Zhangjiagang Guangda Special Material Co., Ltd. |

|

Verified Suppliers

|

|

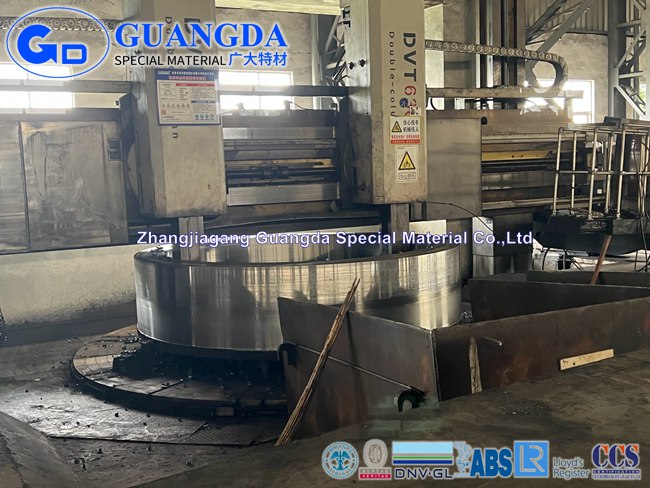

Ring Rolling Forging Max 6300mm Forged Rings Forged Rings Manufacturer

Open die forging is the process of forming and shaping metals by hammering, pressing or rolling. The process begins with starting stock, usually a cast ingot (or a "cogged" billet which has already been forged from a cast ingot), which is heated to its plastic deformation temperature, then upset or "kneaded" between dies to the desired shape and size.

Guangda provide different kind of forging rings . We strictly control the whole production chain, from melt to the rolling of the rings. Guangda can offer rings of diameters up to 6300 mm and weights up to 60,000 kg.

Rolled Rings Open Die Forgings Specifications

| Company type | Science and Technology innovation board listed company. Stock code :688186 |

| Completed supply chain | Guangda is an leading and integrated steel manufacturer from smelting, forging, heat treatment to precision smart manufacturing . |

| Shape | Ring, Shaft, disc, round plate, Dysplasia forgings etc. |

| Annual capacity for the forgings | 300,000.00 ton |

| Max length/Diameter for rings | 6300mm |

| Max weight | 60T |

| Machining | Turning, milling, boring ,grinding, finished machining, gear shaping ,gear hobbing, gear grinding capability. |

| Heat treatment | Normalizing, QT, Soft annealed, Stress relieved, annealing, carburizing, Isothermally annealed, nitriding with complete heat treatment capacity |

| Surface treatment | High-pressure cleaning, sand blasting and thermal spraying. Complete surface treatment capability. |

| QC Certificate | PED,DNV, BV, Rina, ISO, GL, ABS, LR etc. |

Test for Rolled Rings Open Die Forgings

Rolled Rings Open Die Forgings material we could provide

| Type | Material |

| Carbon steel | C15,C22,C25,C30,C35,C40,C45,C50,C55,C60,S355J2G3 etc. |

| Alloy steel | 25CrMo4,42CrMo(S)4,AISI4130,AISI4140,AISI4150,34CrNiMo6,30CrNiMo8, 31CrMoV9,16MnCr(S)5,20MnCr(S)5,51CrV4,20MnCr5,20CrMnMoH 18CrNiMo7-6,etc. |

| Stainless steel | 630 17-4PH,630 17-7PH, 632 15-7MoPH,XM12 15-5PH,2205,2507,F55,2205 etc. |

| Tool and die steel | H11-1.2343,H13-1.2344, 1.2738,1.2718 ,1.2343, 1.2312 ,XPM , NAK80, DVA etc. |

| Special steel | GH2132, GH3030, GH3128, GH4145 ,GH4169 ,GH4080 ,Inconel600 ,Inconel601 ,Inconel625 ,Inconel718 N07718 / GH4169, Inconlex - 750 ,Incoloy800H,Incoloy825,Incoloy901,Incoloy925,Incoloy926 etc. |

About Guangda

Zhangjiagang Guangda Special Material Co.,Ltd was established in

2003, is one of the forging manufacturer for research and

development, production, sales, service as one of the comprehensive

company. We located in Jiangsu Province besides Shanghai. We

provide different forgings of shaft ,gear blank , ring rolling,

rough machining, heat treatment and finish machining. Our annual

production capacity is 500,000 tons for various of free-die

forgings, ring rollings .

We are qualified by the classifications such as PED,DNV, BV, Rina, ISO, GL, ABS, LR .Act as the high-tech enterprises with high-quality special alloy materials as the core business belong to the "advanced iron and steel materials" industry under the strategic emerging industries supported by the state.

There are two major product systems of alloy materials and alloy products:The alloy materials include high quality gear steel, high quality die steel, special stainless steel, high temperature alloy, ultra-high strength steel and other new material products encouraged by the state; Alloy products mainly include wind power equipment, rail transit and various precision mechanical parts made of alloy materials.

Guangda forgings are widely used in high-end equipment manufacturing industries such as new energy wind power, rail transit, mechanical equipment, aerospace, new energy power, gas turbine, Marine petrochemical, semiconductor chip equipment and so on.

Ring Rolling Forging

Forged Rings

Forged Rings Manufacturer