Henan Tytion Machinery Co., Ltd. |

|

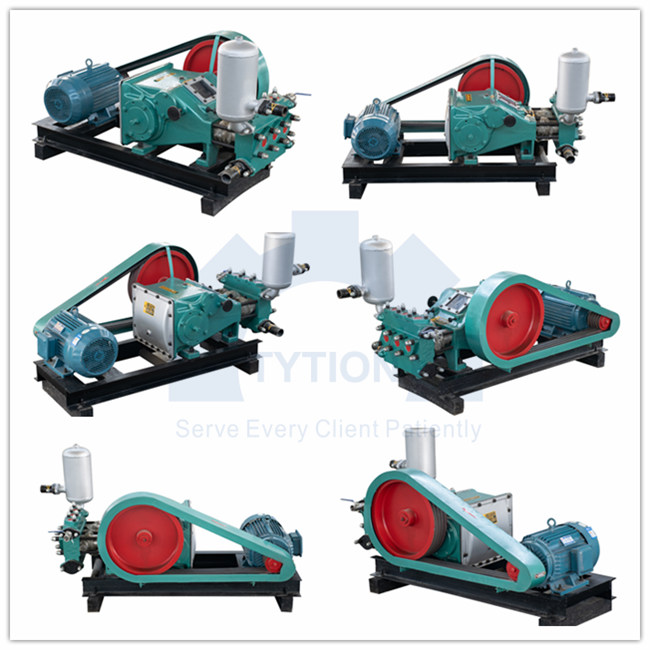

Injection Grouting Machine

Description of Injection Grouting Machine:

Injection grouting machine can pump the mortar, the sand should be screened, the maximum particle size is not more than 5 mm. Sand with particle size less than 1 mm is more than 60% of the total sand. Stones and other impurities (e.g. nails, grass, etc.) should not be mixed in the grouting. It should be a homogeneous mortar with no dry sand or hard blocks. The consistency value is not less than 8 cm and the consistency is 300 G.

Technical parameters of Injection Grouting Machine:

| Cylinder number | 1 |

| Bore diameter | 80mm |

| Piston stroke | 90mm |

| Suction height | 2 meter |

| Diameter of suction pipe | 51mm |

| Diameter of outlet pipe | 32mm |

| Motor power | 5.5kw |

| Main shaft speed | 1440 r/min |

| Working pressure | 5 Mpa |

| Dimension size | 1550×550×80mm |

| Weight | 200kg |

Structure of Injection Grouting Machine:

Injection Grouting Machine is mainly composed of pump body, pump frame, air chamber, shock-resistant pressure gauge, motor, V-belt and pulley cover.

The installation foundation of cement grouting pump should be

smooth and not inclined.

The pump is fixed on the foundation with the foot screw to prevent

the vibration of the pump during operation.

Preparations before pumping:

After the pump has been stopped or reinstalled for a long time, the

following preparations must be made before starting.

1. Check whether there is enough lubricating oil in each part.

2. Check whether the suction pipe of the filter is unblocked.

3. Check whether there is obstruction in the movement of each part.

4. Check the accuracy and reliability of the transmission

mechanism.

5. Check the looseness of fasteners, especially the screw

tightening of rubber piston locking nut, cross head and piston rod

connection thread.

6. Check the suction height of the pump. The maximum suction height

of the pump should not exceed 2.5 meters in areas below 1000 meters

above sea level. In areas above 1000 meters above sea level, the

suction height of the pump should be reduced according to the local

atmospheric pressure reduction.

7.Check the position of the filter immersed in the mud tank.

Generally, the mud level should be below 0.3-0.5 meters, and the

filter should be no less than 0.5 meters away from the bottom of

the mud tank.