Longkou FuChang Packing Machinery Co.,Ltd |

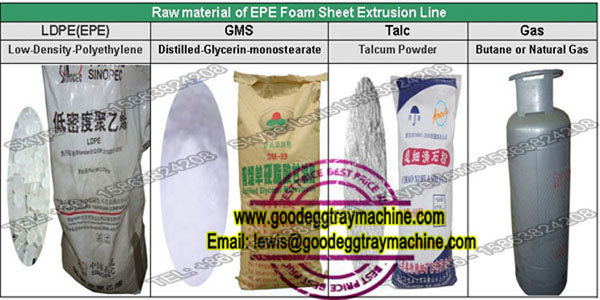

Raw material: LDPE, GMS, TAC, Talc, Butane or Natural Gas

Sheet Width(mm):800-600,1000-2000

Sheet thickness(mm):0.5-3.0,0.5-5.0,0.8-8.0,1.0-10.0,2.0-15.0

Capacity(T/day):2,2.5,3,5,7,10

Good quality EPE foam roll underlay extruder:

EPE Foam Sheet is a new type of packing material also named as pearl cotton .It is an ideal substitute of traditional packing material for many advantages including dampproof, shockproof, sound insulation, heat preservation and high plasticity. As a new type packing material it is widely used in the packing of electronic product, commodity, glass, ceramic, household apparatus, spraying, furniture, hardware product and toy.

| 1.EPE Foam Sheet Extrusion Line Working flow: | |

| 2.EPE Foam Sheet Extrusion Line Working flow: |

Main Technical Parameters of EPE Foam Sheet Extruder Line: | |||||||

Model: |

| FCFPM-90 | FCFPM-105 | FCFPM- 120 | FCFPM-150 | FCFPM-170 | |

Extruder: |

| 90/55 | 105/55 | 120/55 | 150/55 | 170/55 | |

Screw speed: | r/min | 5-45 | |||||

Foaming Ratio: |

| 10-40 | |||||

Product width: | mm | 800-1600 | 1000-2000 | 1000-2000 | 1000-2000 | 1000-2000 | |

Product thickness: | mm | 0.5-3.0 | 0.5-5.0 | 0.8-8.0 | 1.0-10.0 | 2.0-15.0 | |

Cooling Method |

| Air-cooled, water-cooled | |||||

Installed Power | kw | 90 | 100 | 120 | 150 | 180 | |

Dimension: | m | 20×2.3×2.2 | 23×2.3×2.2 | 25×2.3×2.2 | 30×2.3×2.2 | 32×2.3×2.2 | |

Weight: | T | 6 | 8 | 12 | 15 | 17 | |

Contact: | Mr Lewis |

Email: | |

Skype: | lewis15863824208 |

Gtalk: | |

Yahoo Messenger: | |

Mobile: | +86-15863824208 |

Website: | |

We are the professional manufacturer of Pulp moulding Machine and EPE Foam Extruder Line etc in Longkou ,Shandong Province, China. | |