Longkou FuChang Packing Machinery Co.,Ltd |

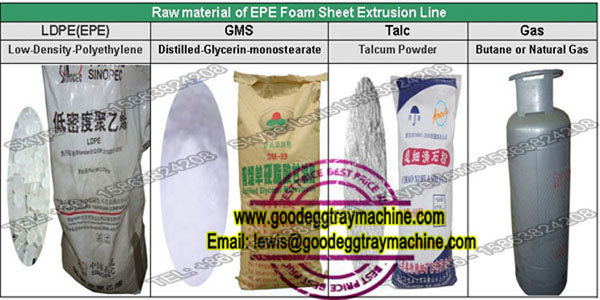

Raw material: LDPE, GMS, TAC, Talc, Butane or Natural Gas

Sheet Width:1000-2000MM

Sheet thickness:2.0-15.0mm

Capacity:7T/day

Main Technical Parameters of EPE/PE/LDPE Peral Cotton Making machine: | |||||||

Model: |

| FCFPM-90 | FCFPM-105 | FCFPM- 120 | FCFPM-150 | FCFPM-170 | |

Extruder: |

| 90/55 | 105/55 | 120/55 | 150/55 | 170/55 | |

Screw speed: | r/min | 5-45 | |||||

Foaming Ratio: |

| 10-40 | |||||

Product width: | mm | 800-1600 | 1000-2000 | 1000-2000 | 1000-2000 | 1000-2000 | |

Product thickness: | mm | 0.5-3.0 | 0.5-5.0 | 0.8-8.0 | 1.0-10.0 | 2.0-15.0 | |

Cooling Method |

| Air-cooled, water-cooled | |||||

Installed Power | kw | 90 | 100 | 120 | 150 | 180 | |

Dimension: | m | 20×2.3×2.2 | 23×2.3×2.2 | 25×2.3×2.2 | 30×2.3×2.2 | 32×2.3×2.2 | |

Weight: | T | 6 | 8 | 12 | 15 | 17 | |

| 1.EPE Foam Sheet Extrusion Line Working flow: | |

| 2.EPE Foam Sheet Extrusion Line Working flow: |

Main Technical Parameters of EPE Foam Sheet Extruder Line: | |||||||

Model: |

| FCFPM-90 | FCFPM-105 | FCFPM- 120 | FCFPM-150 | FCFPM-170 | |

Extruder: |

| 90/55 | 105/55 | 120/55 | 150/55 | 170/55 | |

Screw speed: | r/min | 5-45 | |||||

Foaming Ratio: |

| 10-40 | |||||

Product width: | mm | 800-1600 | 1000-2000 | 1000-2000 | 1000-2000 | 1000-2000 | |

Product thickness: | mm | 0.5-3.0 | 0.5-5.0 | 0.8-8.0 | 1.0-10.0 | 2.0-15.0 | |

Cooling Method |

| Air-cooled, water-cooled | |||||

Installed Power | kw | 90 | 100 | 120 | 150 | 180 | |

Dimension: | m | 20×2.3×2.2 | 23×2.3×2.2 | 25×2.3×2.2 | 30×2.3×2.2 | 32×2.3×2.2 | |

Weight: | T | 6 | 8 | 12 | 15 | 17 | |

Contact: | Mr Lewis |

Email: | |

Skype: | lewis15863824208 |

Gtalk: | |

Yahoo Messenger: | |

Mobile: | +86-15863824208 |

Website: | |

We are the professional manufacturer of Pulp moulding Machine and EPE Foam Extruder Line etc in Longkou ,Shandong Province, China. | |