Doming System is used to apply a two component resin on a label,

decal or another non-porous surface. After curing it becomes 3D,

transparent, giving at the same time mechanical and chemical

resistance properties.

Main advantages:

- Easy to start and use you need to print and kiss

-cut labels or stickers only

- Low investments

- High quality product no environmental influence (UV, water,

temperature)

- Resistant product scratch and chemical resistant (oil, gas,

alcohol etc.)

- Wide operation temperature range from -600C to 1200C

- Additional UV protection protects color of label from UV lights

- NOT toxical

Main applications:

Doming has many applications in various markets: Souvenirs, Gifts

(labels, decals, keyrings, pens, magnets, broaches, pins etc.);

Promotional, POS (business promotional tools, badges etc),

Industrial (identification labels, equipment labels, computer

badges, beer equipment decals, refrigirator and air conditioner

labels, packaging etc.), Interior design (glass, mirror design

elements, protection elements, polymeric mosaic etc.), Textile

design (thermotransfer labels, sew labels, T-Shirt, sport uniforms

and equipment, bags, shoes etc.), Automotive, Tuning (labels for

cars, decals for wheels, decorative elements, sew labels for

interior etc.)

Machine picture

Machine description and working principle

Compound materials A & B are kept in two tanks separately. There are two

sets of metering pumps inside the machine for metering A and B resin by setting ratio, draining out material individually from tank A & B. Liquid A & B mix with

each other in the mixer pipe and dispensed out according to the

programmable data.

Machine Breif introduction

1. The whole bucket of glue only be placed on the tank side of the

machine, and the equipment can be automatically extracted without

manual pouring into the storage bucket.

2. The storage tank can be customized according to the potting of

AB glue in each hour.

3. The storage tank has automatic defoaming function and material

location level detection function.

4. The tank can be customized according to your glue need, such as:

automatic stirring, automatic constant temperature, air drying,

etc. ..

5. High-precision screw pump (gear pump / plunger pump) pushes glue

through the cavity, with high pressure and fast glue output.

6. The servo motor drives the screw pump , the speed of each pump

can be set separately, to keep the flow speed of each pump, To

achieve the required mixing ratio (1: 1--1: 10 adjustable).

7. Equipped with dynamic mixing device to make the mixing of glue

more uniform.

8. Equipped with automatic cleaning function, no need to manually

cleaning the machine, avoid manual cleaning trouble.

9. Equipped with 500 * 500mm mechanical arm, which can edit the

running path, To actual perfect potting ab glue at correct location

on product

Options:

1.Dispensing with Dozing nozzle or Static mixer/dynamic mixer

2.Constant or Variable resin:hardener mixing-ratio

3.Single or Multi Dispenser Potting

4.Fixed or Moveable dosing nozzle (Dispensing)

(X-Y-Z axis movement or interpolation)

5.Automatic Loading & Unloading of Trays

6.Ability to dosing different quantities of raw materials to

different locations in one program

7.Automation: pre-heating and curing oven with conveyor

8.Extra degassing tanks for uninterrupted production

Dosing Pumps

1. Very precise even at very low volumes

2.Constant mixing ratio ensures faultless dosing

3. Metering pumps ensures minimal amounts of reactive mix

4.Temperature controlled design

5. Resistant to abrasion even when filled with high abrasive

casting resins and does not require maintenance

Machine Vacuum Tank Agitator

1. Full homojenization

2.No sedimentation

3. Perfect degassing

Static Mixer /dynamic mixinng

1.Perfect homogenization without dead space

2. Abrasion resistant & low maintanence

3.Temperature controlled design

4. Ensures optimal viscosity of reactive compounds at constant

temperature

5.Provides very long service life with a closed cleaning system

Technical Specifications

1.Vacuum PumpUp to 1mbar

2.Nozzle Movement Motor: AC servomotor Linear X,Y,Z axis

3.Nozzle Movement DistancesX:500mm, Y:500mm, Z:100mm

4. Control SystemPLC

5. Power SupplyTriple Phase 220V +/-10%, 50 / 60Hz

6. Air Pressure6 Bar

7. Touch Screen7 inch

8. Barrel size: 10L,30L,40L for optional

Machine Prameter

Models: | KPD-500 Automatic Multifunctional Glue Potting Machine |

Suitable process: | It can be used as a stand-alone machine or with the customer’s

original assembly line to achieve on-line gluing. |

Proportion of glue: | 10:1 – 1:1 |

hybrid approach: | Dynamic stirring mixing/static |

Machine Stroke: | 500x500x100mm |

speed | X,Y axle 400mm/s |

accurate | ±0.05mm |

Programme stock: | 999 |

programmer | Teach-In Programming |

metrological: | High precision metering pumps |

control method: | PLC+touchscreens |

input method: | Touch screen + buttons + IO |

Appearance Material: | Industrial square tube welding + 6061 alloy + cold rolled plate |

Drum size: | A barrel 30L, B barrel 10L (can be customised) |

External Dimensions: | 1100×1350 X1600mm |

Gum flow rate: | 1–80g/5sec (customised large glue volume available) |

trajectory: | Punching points, walking straight lines, curves, drawing circles,

arcs, squares, and other irregular shapes. |

Supply Voltage: | AC220V/50HZ |

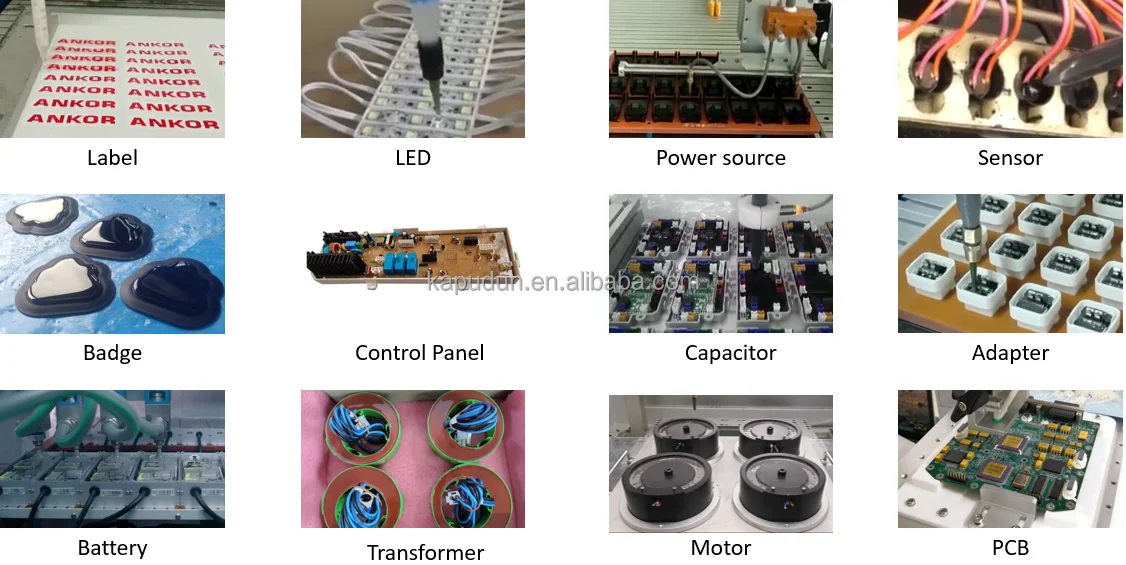

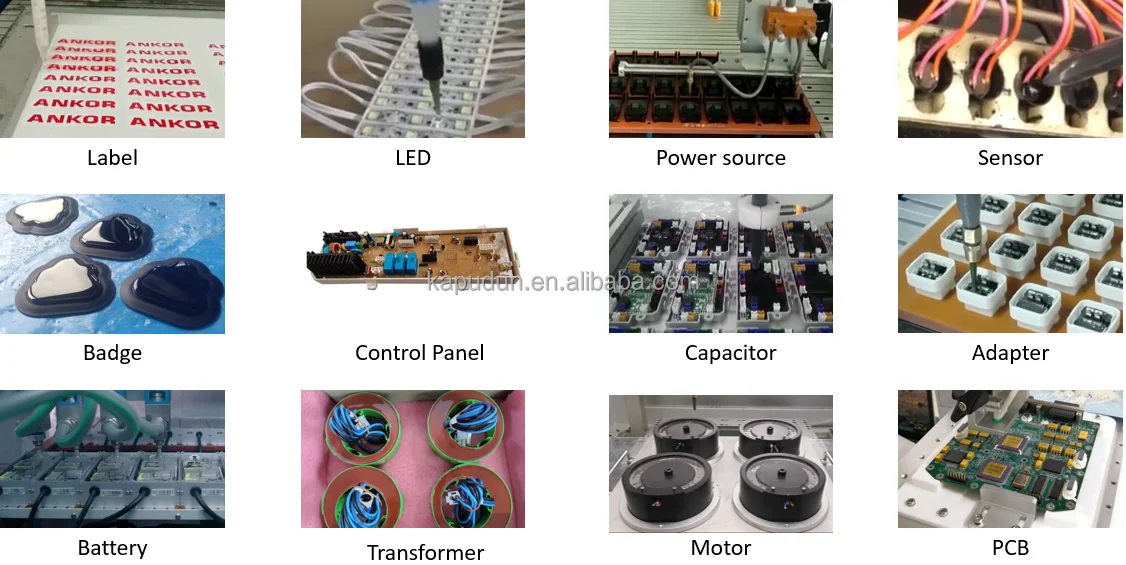

Applications:Potting&isolation &Casting: electronics componnets , PCB board, Capacitor, power supply, transformer, ignition coil, reverse sensor,

circuit board, filter products ,underwater parts, electronic ballast ,aviation parts, aerospace parts.... Dispensing&Dosing : LED strip , led lamp , led bulb , aluminum,led screen , display module ,medical parts,medical liquid filling ....

Bonding&doming : LCD screen ,LOCA bonding,ABS plastic,different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics....

Transformer , capacitance , power module , regulating plate

,protection module , generator , pressure package , soli relay

,fault indicator , Sensors , junction box , clutch , wave filter ,

water meter , boattery cover , rectifier and so on ...

Suitable Material

1K and 2-component polyurethanes, epoxies, acrylics, silicones,

temperature, humidity and UV curing materials.Two component potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU, Ployerster, Polyurethane, UV materials and so on .