FOSHAN STAR TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

| Machine dimensions | 8300*1600*2900mm |

| Max glass size | 2000*2500mm |

| Min glass size | 300*350mm |

| Glue thickness | 2mm -15mm |

| Insulating glass finished product thickness | 12mm - 60mm |

| Singe glass thickness | 3-15mm |

| Sealing speed | 4-40 meters/minute (6A spacer bar, 5mm glue depth specification bar) |

| Transmission speed | 4 - 40m/min |

| Load weight | 300kg/m |

| Sealing ambient temperature | 15-40ºC |

| Control method | touchscreen |

| Gas source | Pressure 6Bar , Maximum air consumption 2.0Ms/min |

| Power | 10kw , 380V (50HZ) |

| External wiring entrance | 10m2 wire 63A circuit breaker (5 wires) |

No. | ITEM | BRAND |

1 | Servo motor driver | Yaskawa |

2 | Stepper Motor Driver | Shenzhen Lesai |

3 | 10.4 Touch screen 10.4 inches | Taiwan Wei Lu |

5 | Motion Controller | Yaskawa |

6 | PLC PLC module | Yaskawa |

7 | Frequency converter | Yaskawa |

8 | Low voltage electrical appliances | Schneides |

9 | Photoelectric switch | Korea Autonics |

| No. | ITEM | BRAND |

| 1 | The electromagnetic valve | Taiwan Yadeke |

| 2 | Vacuum suction cup | Festos, Germany |

| 3 | Vacuum generator | Festos, Germany |

| 4 | Precision pressure reducing valve | SMC Japan SMC |

| 5 | Electric proportional valve | SMC Japan SMC |

| 6 | Oil mist separator | SMC Japan SMC |

| No | Iterm | Specification | Material | Brand/Origin | Model |

| 1 | Linear slide | HGW 25CC | high frequency processing | TAIWAN | HSR25 |

| 2 | Linear slide | HGW 15CC | high frequency processing | TAIWAN | Z2-25×50 |

| 3 | Deep groove ball bearing | 6202 | CHINA HARBIN | LMEK25L | |

| 4 | Extended square flange linear bearing | LMEK25LUU | CHINA |

Company Profile:

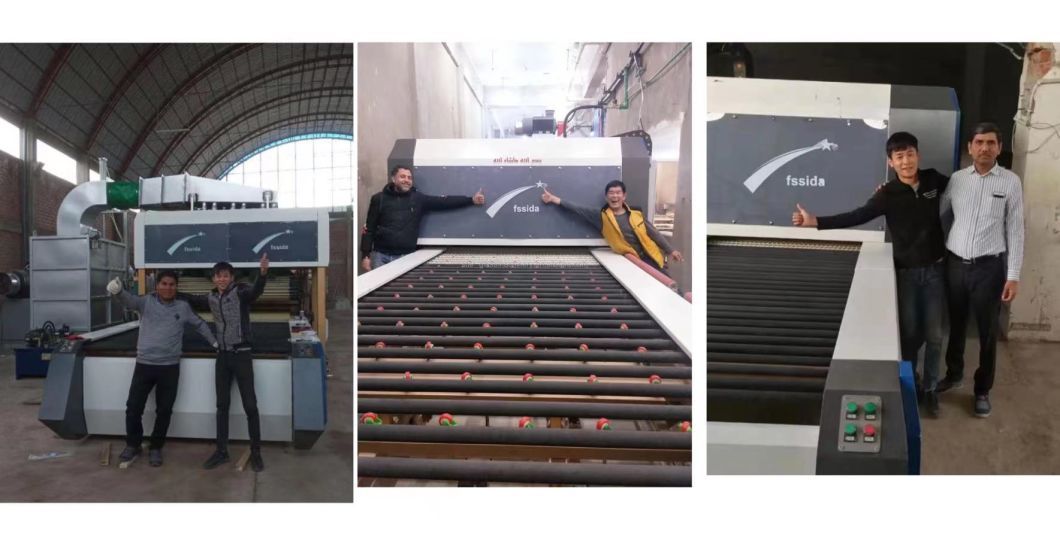

Founded in 2010, Foshan Star Glass Machinery Co., Ltd. is a

high-tech enterprise specializing in the

production, research and development and sales of glass deep

processing machinery. The company is

located in Foshan City, a major glass machinery center.

The company is committed to the production of glass radiant

tempering furnace, convection tempering

furnace, flat bending dual-purpose tempering furnace, automotive

glass bending furnace, nonautoclave

PVB laminating production line.

After years of hard work and exploration, the company has obtained

a number of national patents, and

its technology is ahead of the domestic level. The products sell

well all over China and are exported to

Australia, the United States, the Middle East, India, Vietnam,

South America and other places.

Companies adhering to the principle of quality first,

service-oriented, and constantly improve the

company's level and product quality, and strive to create a

skilled, high-quality team. We will sincerely

cooperate with new and old customers at home and abroad with

sincerity and jointly develop the

bright road of glass machinery manufacturing industry.

nExhibition

1. who are we?

We are based in Guangdong, China, start from 2011,sell to South

America(30.00%),Southeast Asia(20.00%),Mid East(15.00%),Eastern

Europe(10.00%),Africa(10.00%),North America(10.00%),Western

Europe(3.00%),Eastern Asia(2.00%). There are total about 11-50

people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Glass Machine,Glass Furnace,Glass Bending Furnace,Glass Bending And

Tempering Furnace,Glass Machines

4. why should you buy from us not from other suppliers?

Our company has a professional R & D team and a strict quality

management system. 10 years of export experience. Mature

after-sales installation team.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,DDP;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit

Card,PayPal,Western Union,Cash,Escrow;

Language

Spoken:English,Chinese,Spanish,Japanese,Arabic,French,Russian