Jiangsu Gaoqi Machinery Co., Ltd |

|

Verified Suppliers

|

|

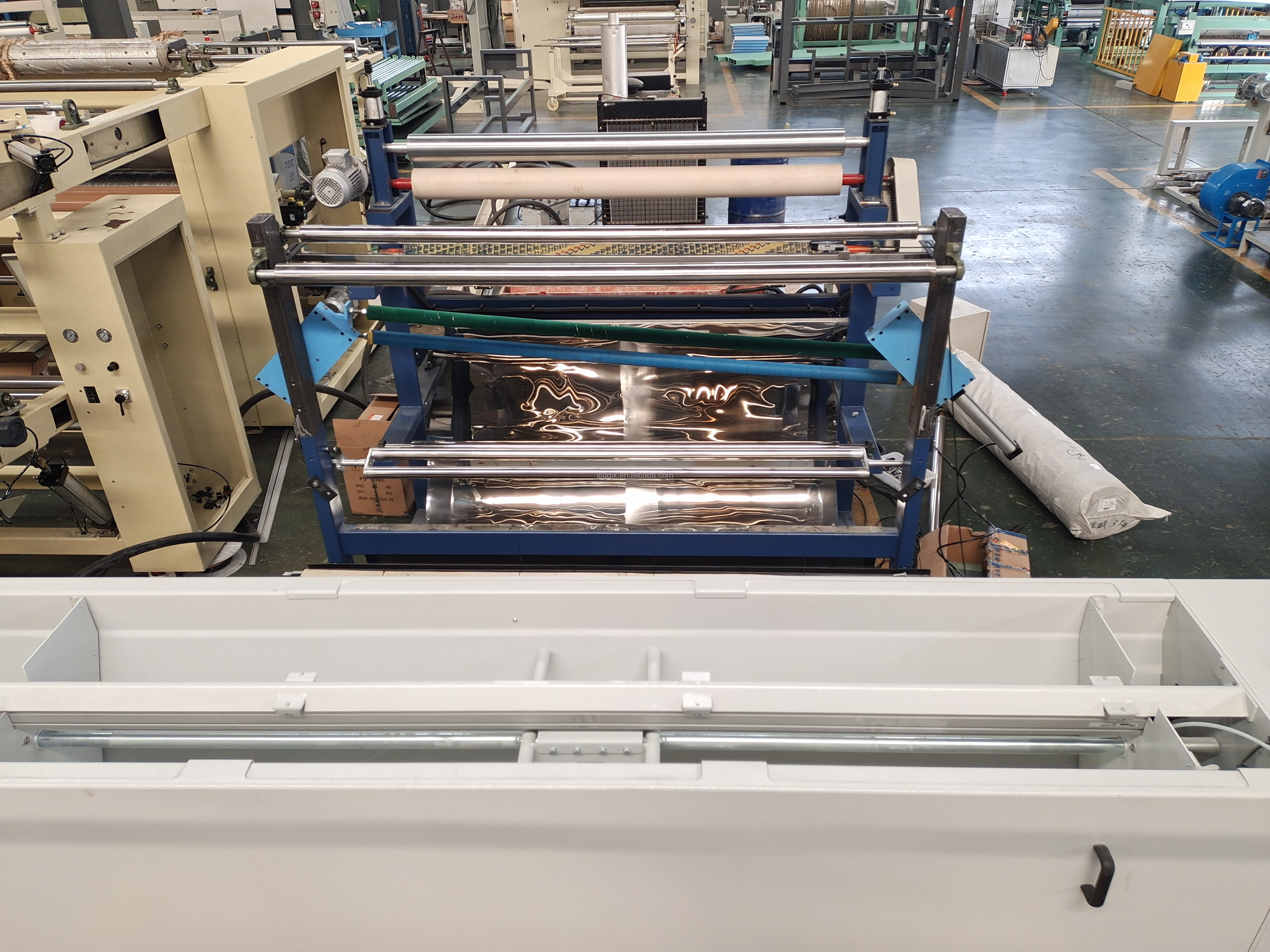

Product | Hot Melt Powder Scattering Coating Laminating Machine |

Brand | GAOQI |

Power supply | 380V, 50Hz, three-phase |

Process speed | 25-35m/min |

Applications: This machine adopts powder dot transfer and coating method to uniformly transfer the hot melt powder onto the substrate. It is suitable for powder-dot coating of pure cotton, poly cotton or other blend fabric about 50-135 g/m2, also it can produce low pressure polythene powder-dot interlining cloth, polyamide (nylon PA) powder-dot interlining cloth, polyester powder-dot interlining cloth, the coating of powder-dot interlining cloth is coated even, also it can fit cotton, leather or fiber to produce all kinds of garment. |

Notice before purchasing duster: A. Please advise what kind of materials need to be dusted,

such as non-woven fabric, felt, composite material, fabric,

leather, etc B. Please advise the thickness (gram weight), width and dusting

effect of the material. C. Please advise the effect configuration, such as automatic,

semi-automatic, volume to volume, volume to match, etc D. Please advise the industry scope of the materials to be dusted |