Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Advanced Manufacturing Technology 304SUS Tomato Production Line 100T/D

Product description of tomato processing plant

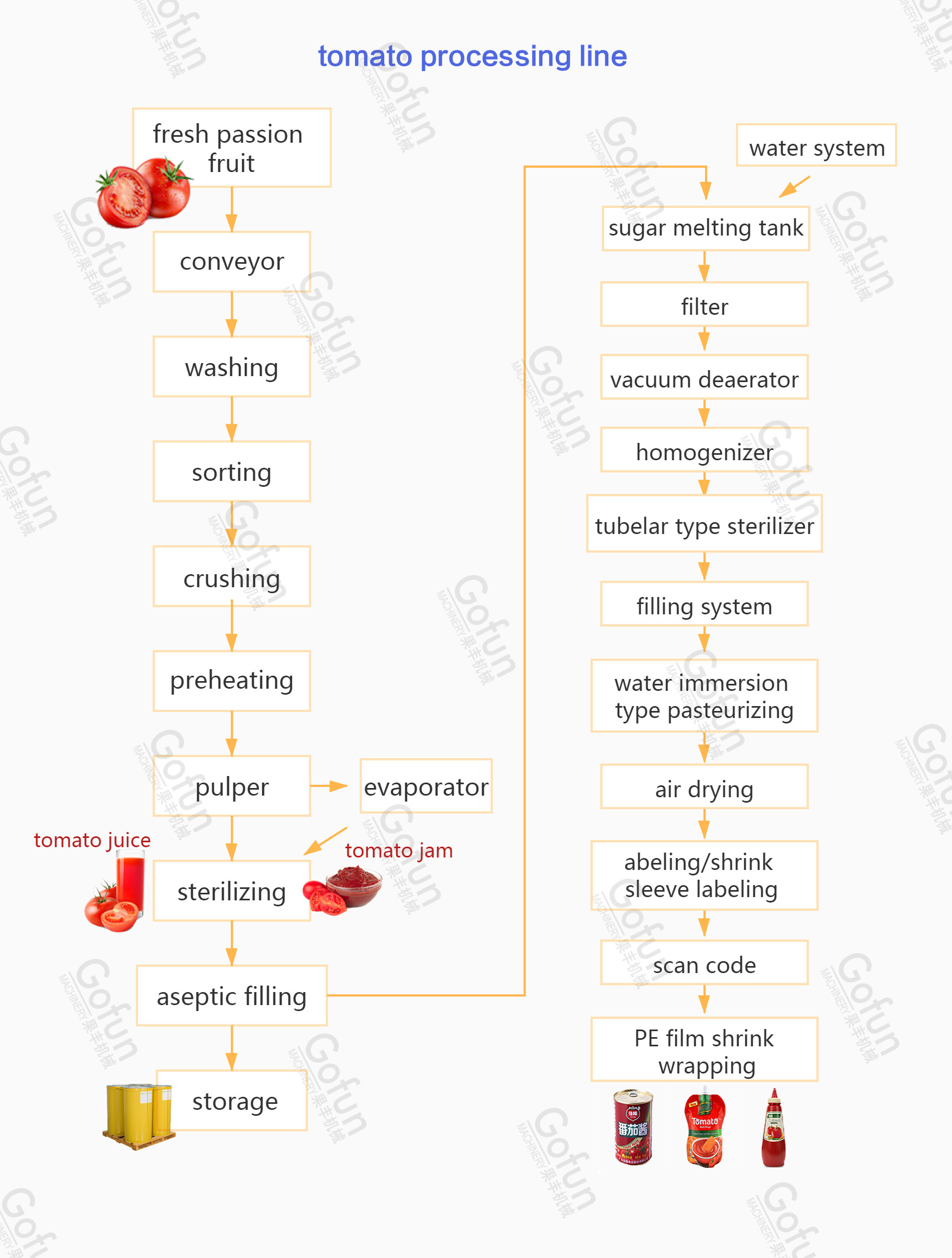

The tomato processing line is designed to transform fresh tomatoes into various final products, including popular items such as tomato paste, tomato sauce, ketchup, and tomato juice. The processing line consists of several essential components: a fresh tomato receiving system, a washing system, a sorting system, a crushing system, a pulping and refining system, a filtration system, a concentrating system, a sterilizing system, and an aseptic filling system. By following this process, we can obtain tomato paste packaged in aseptic bags within drums.

Furthermore, the tomato paste in aseptic bags can undergo further processing to create tomato ketchup, sauces, and juice. These products can be packaged in sachets, stand-up pouches, metal cans, PP containers, bottles, gable tops, and other suitable packaging formats.

Gofun can not only provide the tomato processing equipment for the plant but also provide the one-stop solution from A to Z, which includes:

Main parameters of tomato production line

| Product name: | One-stop solution for tomato processing line |

| Fresh fruit input capacity: | 500kg per hour ~ 25 tons per hour |

| Raw material: | Fresh tomato, tomato paste |

| End product: | Tomato paste, tomato sauce or ketchup, tomato juice, etc |

| Final product Brix: | 28%~30%, 36%~38% |

| Final package: | Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc |

| The main material for machines: | Food grade SUS304 or SUS316 |

| Warranty: | 12 months after commissioning |

| Operator needed: | About 10~12 persons |

| Voltage: | 380V 50Hz/ 110V 60Hz/ 415V 50Hz |

| (adjustable to client's country standard) | |

| Advantages: | Energy-saving, high efficiency, water-saving |

Flowchart of tomato paste/ sauce or ketchup processing

FRESH TOMATO ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ PREHEATING ⇒ PULPER & REFINER ⇒ EVAPORATING ⇒ STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

Case photos

Features

1. Low price and high cost-effectiveness: The price is the most favorable among peers for the same quality.

2. Quality and reliability: The equipment complies with international standards and

certifications, such as ISO certification, etc.

3. Adaptability and flexibility: The flexible production line can handle tomato products of

different specifications, packaging and processing methods.

4. Energy efficiency: Consider choosing energy-efficient equipment to reduce energy

costs and reduce dependence on energy.

5. Local adaptability: Ensure that the equipment adapts to the local environment and

working conditions. Select equipment appropriate for the region,

taking into account factors such as climate conditions, power

supply, equipment size, and equipment installation requirements.

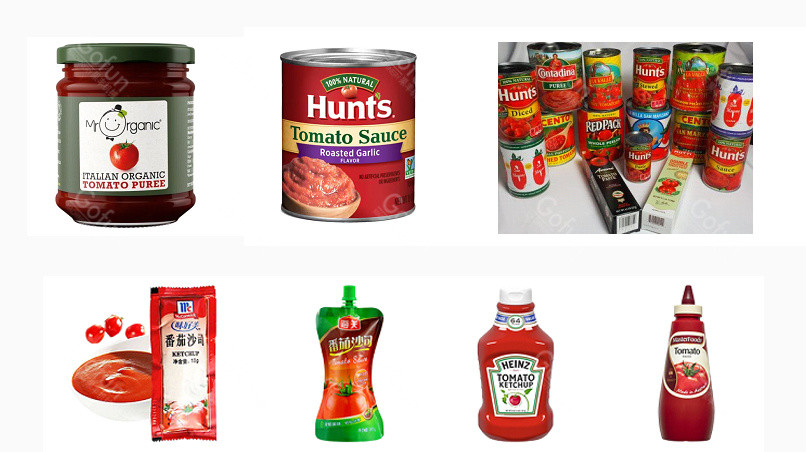

Final products & Package types for tomato project

Shanghai Gofun machinery company offers all kinds of the tomato processing line.

The raw material can be fresh tomato, tomato paste, etc. And the final product can be tomato paste, tomato ketchup, tomato sauce, tomato juice, tomato powder, whole peeled tomato, etc.

For the final package, it can be an aseptic bag, metal can, sachet, stand-up pouch, PP container, glass bottle, PET bottle, gable top, etc.

After-Sales Service

1. Oversea technical support

2. Oversea equipment maintenance

3. English speaking engineers available to provide technical support

Our Services for tomato processing plant

1. Technical support

2. Marketing suggestion

3. Final packing suggestion and design

4. Factory building and design