Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Long Service Life Ss304/316L Tomato Ketchup Processing Line 1-10T/H

Product description of tomato processing line

The tomato processing line is to process fresh tomatoes into different types of tomato products. Such as tomato paste, tomato sauce & ketchup, and tomato juicer from raw tomatoes to final products in aseptic bagged drums.

Barrel Aseptic Bag Ketchup can also further pack ketchup, sauce, juice, in pouches, stand-up pouches, metal cans, PP containers, bottles, gable tops, etc.

Main parameters of tomato production line

| Product name: | One-stop solution for tomato processing line |

| Fresh fruit input capacity: | 500kg per hour ~ 25 tons per hour |

| Raw material: | Fresh tomato, tomato paste |

| End product: | Tomato paste, tomato sauce or ketchup, tomato juice, etc |

| Final product Brix: | 28%~30%, 36%~38% |

| Final package: | Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc |

| The main material for machines: | Food grade SUS304 or SUS316 |

| Warranty: | 12 months after commissioning |

| Operator needed: | About 10~12 persons |

| Voltage: | 380V 50Hz/ 110V 60Hz/ 415V 50Hz |

| (adjustable to client's country standard) | |

| Advantages: | Energy-saving, high efficiency, water-saving |

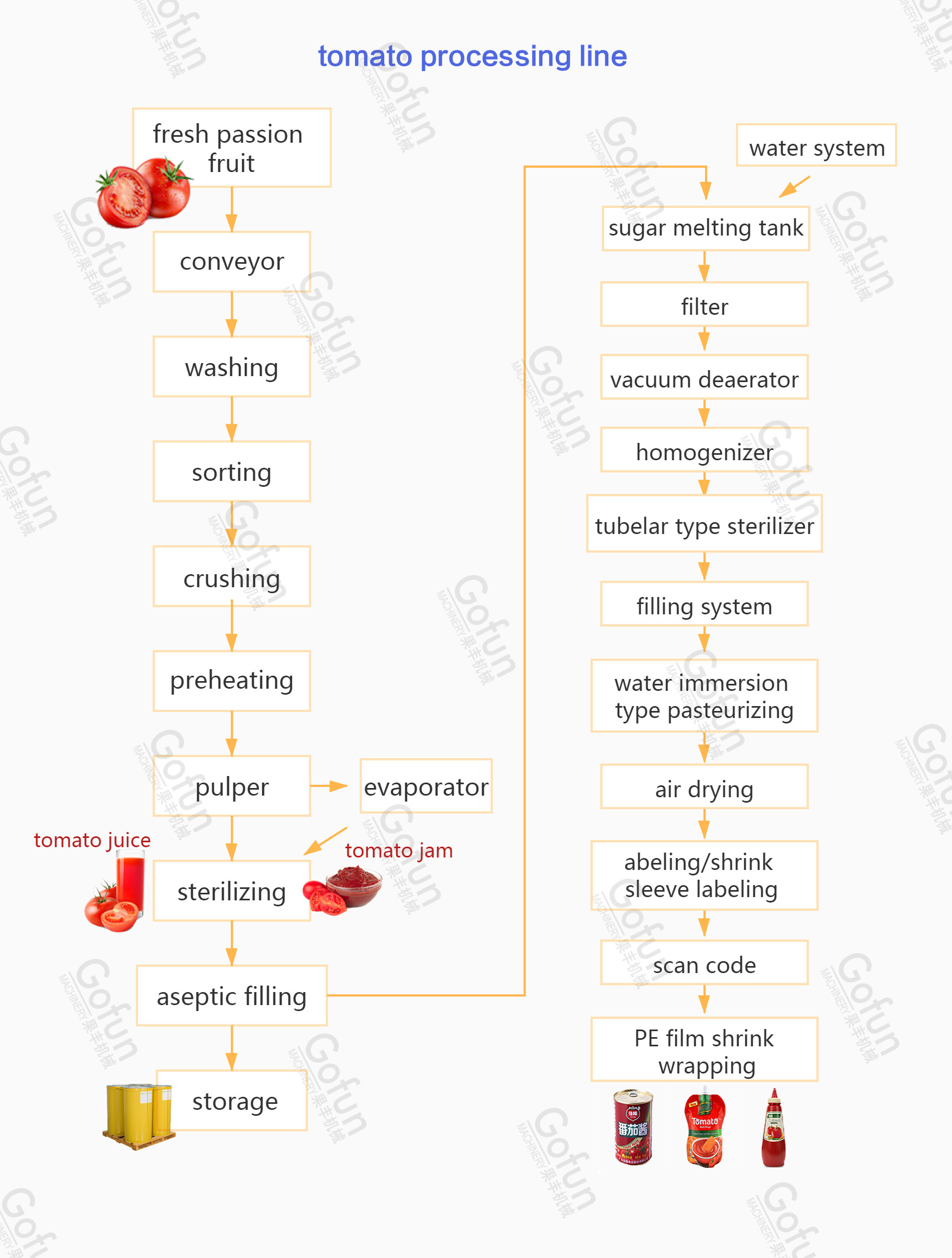

Flowchart of tomato paste/ sauce or ketchup processing

Key process of the tomato paste processing line

Now Shanghai Gofun Machinery Co., Ltd. will briefly introduce the steps of the tomato paste processing production line and show its working principle.

1. Discharge platform

Fresh tomatoes are generally transported by truck. So we designed an unloading platform that uses water guns to unload the fresh fruit/tomatoes from the truck and water to transport the fresh fruit/tomatoes to the processing line. The unloading platform also has the ability to pre-wash fresh fruit and tomatoes before processing.

2. Elevator

This device is utilized for transporting fresh fruit from the exterior of the building to the interior.

3. Washing

Prior to being crushed, fresh fruits ought to be thoroughly cleaned by washing. It is feasible to employ both a bubble washer and a spray washer concurrently. For more stringent cleaning needs, supplementary cleaning steps may be incorporated. Moreover, the cleaning efficacy can be improved by integrating ultrasonic and ozone cleaning methods.

4. Sorting

Subsequent to the washing process, the surface of the fruits will be clean, and a visual inspection can be conducted by humans to assess the condition of all fruits. Any defective tomatoes can be manually sorted out during this process.

5. Crushing for tomato processing

The GFM-FC series crusher has the most advanced working principle, higher manufacturing precision and highest crushing capacity. This machine is primarily employed for grinding a variety of fruits and vegetables, including but not limited to tomatoes, apples, pears, strawberries, and celery. By crushing the raw materials into small particles, the efficiency of subsequent processing stages can be improved. The machine is composed of several components, such as a feed hopper, side cover, frame, main shaft, bearing block, motor, motor structure, and exit hopper.

6. Preheating

A pre-heater is used to heat the product after grinding, and the temperature is usually adjustable from 45°C to 85°C. This processing step helps increase the juice percentage for the next step and can also preserve the color and taste of the final product.

7. Pulper and refiner

The machine also operates at a speed of 1470 r/min, generating centrifugal force to push the product through the screen, helping to refine the product. I usually use two stages, Pulper and Refiner, but each stage has a different screen. The first stage makes the screen bigger and the second stage makes the screen smaller. Two-stage pulping machine for tomato pulp can reach a yield of 90%-95%. After pulping, separate the tomato skin and seeds from the tomato pulp. The machine works with large capacity and stable performance. Easy to operate and replace sieves. Suitable for many kinds of fruits, such as passion fruit, tomatoes, peaches, apricots, mangoes, apples, etc.

8. Evaporating

The vacuum evaporator is specifically designed for the concentration of tomato sauce under low temperature and vacuum conditions, utilizing a forced circulation system. By employing vacuum cooking, the flavor and nutrition of the sauce can be maximized. During the process, the water present in the tomato pulp is evaporated, resulting in the formation of tomato sauce with a typical Brix level of 28-30% or 36-38%.

9. Sterilizing

A tube-in-tube sterilizer is used to sterilize tomato paste. Sterilization temperature and holding time are adjustable. This machine is used to heat tomato paste to a very high temperature of about 115°C, hold for 30 seconds, and then rapidly cool to ambient temperature. As long as the whole system employs programmable control, it can also be protected. The operation system uses a visual man-machine interface that is convenient for intuitively grasping the operating status of each part of the device.

10. Aseptic Filling

The aseptic filling machine operates in tandem with a tube-in-tube type sterilizer, forming a closed system. Prior to production, the entire system undergoes full sterilization to establish an aseptic environment. Additionally, the filling cavity is protected from steam to maintain a sterile filling environment. Various security measures are implemented, including the use of mirror welding technology to achieve clean and seamless welding lines, as well as an independent control panel. The sterilizer is equipped with CIP and Auto SIP functions, and it can be easily adjusted to accommodate different capacities and sizes of sterilization bags.

11. Storage or go blending

The finished product can be saved or used as an ingredient in tomato sauce or ketchup.