Changshu Changhua Zhizao Technology Co., Ltd. |

|

Dual System 52inch 3/5/7G Flat Knitting Machine

PRODUCT DESCRIPTION:

Different types of garments that we can knit on flat knitting

machines range from edgings, trimmings and collars to garment

panels and integrally knitted garments. We can efficiently

manufacture products like jumpers, pullovers, cardigans, dresses,

suits, trouser suits, hats, scarves as well as many other

accessories on these straight-bar machines.

Articles knitted on flat machines range from trimmings, edgings and

collars to garment panels and integrally knitted garments. The

common products: jumpers, pullovers, cardigans, dresses, suits,

trouser suits, hats, scarves, accessories, ribs for straight-bar

machines (fully fashioned machines). Cleaning clothes,

three-dimensional and fashioned products for technical

applications, multiaxial machines are under development.

PRODUCT FEATURES:

| Gauge | 3G,3.5G,5G,7G,5/7G,9G,10G,12G,14G |

| Knitting width | 52,56,60,66,72,80,88,100inch |

| Knitting system | double System |

| Knitting function | Stitch Trasfer, independent suspension,pointelle,intarsia,jacquard,apparent or hide shaping and other regular or inregular patterns. |

| Knitting speed | Controlled by servo motor with 32 sections optional, Max 1.2M/S.The serve motor combines precise feedback control system with high-speed digital signal processor(DSP)to control IGBT to achieve accurate electric current output. |

| Racking system | Controlled by AC servo-motor,racking within 2 inches an with fine adjusting function. |

| Stitch density | Controlled by stepping motor, 32 sections stitch selectable adjustable scopesupported by subdivision technology: 0-650, the length of the knitwear can be accurately controlled. |

| Stitch transfer | Triangular integrated designing enables independent or simultaneous stitch transfer to realize more efficient production. |

| Roller system | Infrared alarm,Computer programs instruction, stepper motor control,32-stagetension selection with an adjustable range between 0-100. |

| Yarn carrier | 4 guide rails and 2*8 nozzles,shiftable at any postion of the needle bed. |

| Protection system | The machine alarm system will set off when yarn-breaking, knots, floating yarn,rewinding, end of knitting, racking failure, needle breakage or Program error, also set up the safety auto-lock protect device. |

| Control system | 1. LCD touch screen, graphical interface.USB and network compatible,with expanded memory of up to 2G.A great amount of patterns can bestores and mobilized for use at any time as perproduction requirements. 2. Monitoring display:Various operating parameters can be displayed and can be adjusted anytime when the machine is running,making operations as convenient and time-saving as possible. 3. Design system and control system(software)are easy to update for free. 4. Multi-language operating system:There are Chinese,English,Spanish andArabic Versions.Languages can be switched according to customer requirements. |

| Network function | High speed network can coordinate up to 250 machines;the knitting data can be uploaded downloaded and shared. |

| Power | Single-phase 110V/220V/three-phase 380V,adopt advanced CMOS technology,having memorizing function at power shock stop.(Optional British plug) |

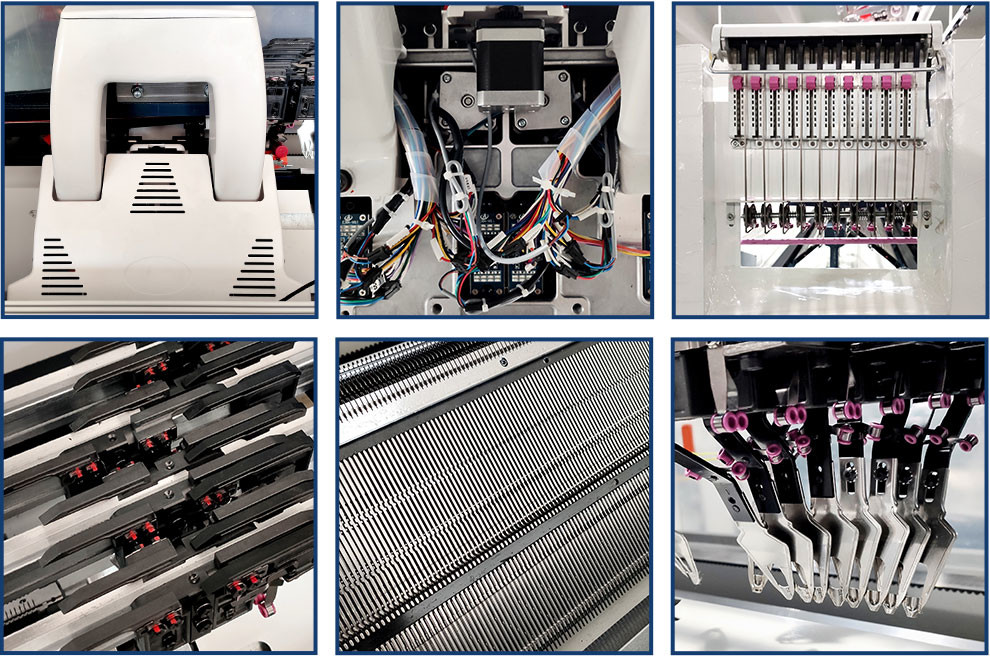

PRODUCT DETAILS

Rack: There are two hills, and two beams connect the hills into a whole, which is a casting. A wrench, a wrench fixing screw, a needle support plate screw, and a needle support plate screw compression spring are installed on the rack.

Needle plate: The steel plate is obtained by refining and heat treatment of high-quality steel, with considerable wear resistance and rust resistance. Slotted holes are milled, and there are large bead, small bead, machine needle, tofu block and fixing screws.

Guide rail: The guide rail is made of castings or special steel. It is fastened to the frame with fixing screws. Generally, there are two front and rear, which are the rails for the machine head. There is a yarn feeder guide above the rear guide rail, which is mainly used for It is used when the yarn feeder moves smoothly left and right with the random head or when changing the yarn feeder.

Faucet: the heart of the flat knitting machine, the parts of the whole machine head are installed on it, its parts include front and rear faders, pusher coke balls and screws, pusher sliders, and bearings are installed on the sliders. The front part of the faucet is equipped with a three-eye cover. The screw that passes through the three eyes is a needle-pulling triangle pull rod. The screw in the center eye is called a live-heart pull-rod screw, a pull-rod well ring and a needle-pulling triangle wrench, a live chicken heart wrench, and a machine head.

The scale plate on the surface is called the scale plate, the small green pressure plate is installed on the scale plate, and the screw in the center of the scale plate is called the two-head screw. The lower ends of the two screws are fastened to the big triangle, the center of the two screws is equipped with a pointer, and the pointer is equipped with an ingot screw. A shuttle rack is installed behind the faucet, and the shuttle rack is equipped with a swing rod and a shuttle rod, and a latch switch is also installed at the back of the machine head. The main part above the machine head is the flower plate.

Flower plate: The flower plate is the center of the flat knitting machine. It has a base plate seat and a panel structure. All triangles are installed on the base plate seat. The triangles on the flower plate include needle triangle, chicken heart triangle, herringbone triangle, and big triangle.

Lead frame part: used to thread the wool yarn output from the bobbin, which can eliminate or reduce the tension fluctuation of the wool yarn, and ensure that the two edges of the fabric are tightly and evenly stitched. It consists of thread take-up spring, adjusting nut and disc tensioner. The elastic force of the thread take-up spring is controlled by the pressing nut, and the clamping force of the disc tensioner is controlled by the adjusting nut.

Yarn feeding part: used to convey wool yarn for weaving.

Pulling mechanism: It adopts heavy hammer pulling, which is used for weaving middle opening and pulling fabric.

Notice:Do not mix the original machine needles with other types of needles on one machine!

APPLICATION FIELDS

PACKAGE AND TRANSPORT:

To make sure the product you buy is safe during transportation,we

use plastic package+wooden package.

In addition,we provide complete packaging methods according to your

requirement,and provide convenience for loading,uploading and

storage as well as save time for checking and delivery.