Hubei EverFLON Polymer Co.,Ltd |

|

PVDF Resin / MFI 3-6 / Virgin Pellets / Molding Processing / Lining Application

it is one kind of pellet PVDF with lower Melting viscosity and suitable for make various PVDF products through injection.

The products made from it have good thermal resistance, outstanding chemical resistance, high mechanical strength and toughness, high abrasion resistance, high dielectric strength, good stability under ultraviolet and nuclear irradiations. It has a wide range of service temperature (-50°C to 150°C).

Brief Introduction

Everflon® PVDF is a fluorinated semi-crystalline thermoplastic which is obtained by polymerizing vinylidene fluoride. Without any additives, it has the intrinsic stability inherent to fluoropolymers even when exposed to harsh environments, providing the user wdith a unique combination of properties resulting in longer equipment life.

Data List of Everflon PVDF Resin H2003

| ITEM | UNIT | ASTM | H2003 |

|---|---|---|---|

| Melt Flow Rate | g/10min 372℃ | D2116 | 3-6 |

| Tensile Strength | Mpa | D638 | >35 |

| Elongation | % | D638 | >300 |

| Melting Point | °C | D4591 | 170 |

Main Processing Way of Everflon PVDF Resin H2003

The Everflon PVDF H2003 Granule is main for Moulding processing.

Properties of Everflon PVDF Resins

• Chemical inert to most acids, aliphatic and aromatic organic

compounds, chlorinated solvents, alcohols

• Very high purity

• Abrasion resistance comparable to that of polyamides

• Low coefficient of friction

• Continuous use within a wide range of temperatures

• Unaffection by UV and good resistance to γ radiation

• Excellent intrinsic fire resistance

• Physiological harmless and approved for contact with food

products

• Good capability for thermoforming and very easily joined by

welding

Main Application of Everflon PVDF H2003

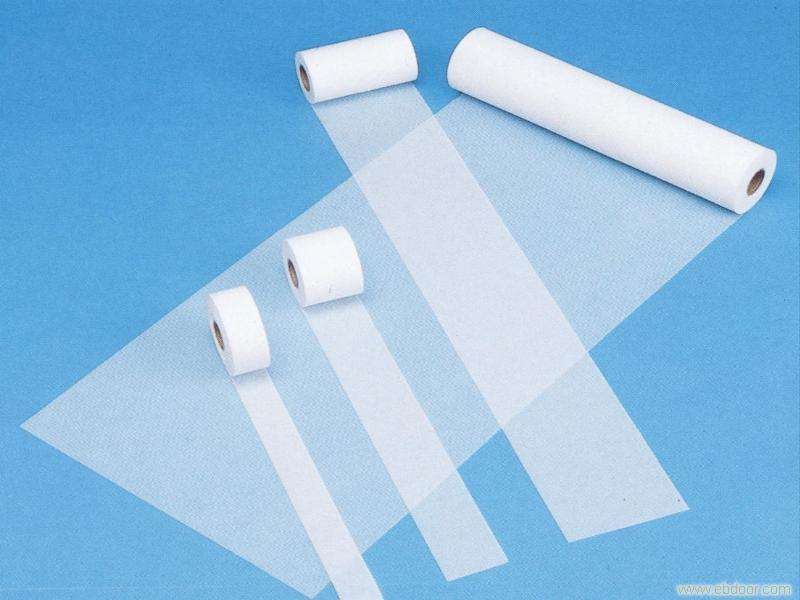

1. Lining

2. Films

Package&Delivery

The properties of Everflon® PVDF resins are not affected by storage time. Ambient storage conditions should be designed to avoid airborne contamination and water condensation on the resin when opening and emptying the packaging.

Everflon® PVDF is packaged in 25-kg, single layer, plastic bags. For convenient shipment, orders of 1,200-kg pallets are recommended.

Before processing, please read the Materials Safety Data Sheet carefully. You could find them from www.everflon.com, or contact us +86-27-84888055 or our local service center, you also should could scan the QR code which on the package to download by your Smartphone.