jiangsu jzer Automation Technology Co.,Ltd. |

Touch Screen Disposable Face Mask Machine With Independent Innovation Design

This machine is mainly used for the automatic forming of flat masks. After the entire roll of fabric is unrolled, it is driven by rollers, and the fabric is automatically folded and wrapped. Nose bridge rolls unrolled by traction. Cut and import into the hemmed fabric, both sides are welded to seal by ultrasonic welding, and then through the ultrasonic side seal. It is cut and shaped by a cutter; transported to the two mask ear band welding stations through an assembly line. The final mask is formed by ultrasonic welding. After the mask is made, it is transported to flat belt line and collected.

Automatic mask production line, also known as one to three mask production line, composed of a mask body machine and three ear band composed of welding machine. Compared with the single independent type mask making machine, joined the automatic conveyor belt and the connecting port, the unique design in addition to improve the production efficiency, reduce artificial cost, is in order to minimize the artificial participation, and reduce the risks of a mask is pollution in the production process.

Main function

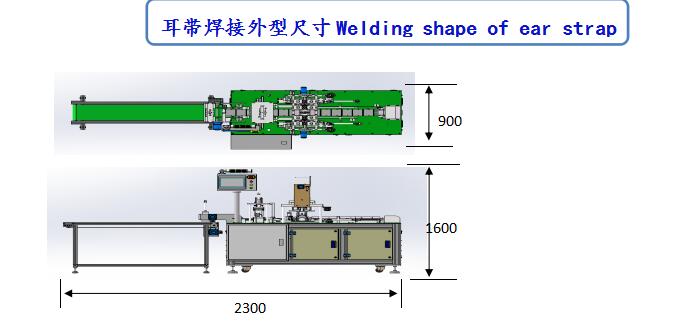

high-speed full-automatic one-tow-two mask machine is mainly composed of the body machine, the flap conveying line and two ear band welding machines.After the machine outputs the mask body, the conveyor belt structure transmits the mask body piece to the turnover mechanism. The mask disc is flipped onto the conveyor belt connected to the ear strap machine by a flip mechanism, then the mask sheet will be transported to the front of the ear belt machine above the mask plate through the conveyor belt, place the mask sheet into the mask plate of the earband machine by pressing down the cylinder, subsequent welding of the ear bands of the mask by the ear band machine, to complete the production of a flat outer ear mask product, the layout of the automatic line is as follows,the whole line is one - tow - two structure.

Features

1. Aluminium alloy structure is adopted, which is beautiful and firm without rust.

2. Computer PLC programming control, high stability, low failure rate and low noise.

3. Servo motor imported from Taiwan, stepper motor drive, high precision.

4. Photoelectric detection of raw materials to avoid mistakes and reduce waste.

5. This equipment can supply 2 inner ear strap machines or outer ear strap machines.

6. The machine adopts pulleys and fixed feet, which is convenient and fast to move, strong in fixation and unshakable.

7. This model is equipped with a new advanced conveyor belt, which automatically collects products with high accuracy, and only needs to be sorted and packed.

technical parameter

1. The length, width and height of the machine: the size of the whole machine is subject to the actual 6500MM * 3500MM * 1600MM

2. Voltage: AC220V 50-60HZ

3. One-to-two production efficiency: more than 100 pieces / min

4. Power: 3.5KW

technical parameters:

Import raw materials, automatic feeding, nose line cutting / feeding, hemming welding, folding scene, forming welding, photoelectric detection, automatic slicing, finished product output, receiving tray sorting, full automation

No. | Name | Parameter |

| 1 | size | 6500 (length) * 3500 (width) * 1950 (height) |

| 2 | Weight | Total equipment weight ≤5000KG Ground load 3500KG / ㎡ |

| 3 | Color | Color Sheet metal warm gray 1C, primary color of aluminum profile |

| 4 | Working power supply | 220VAC ± 5% 50HZ grounding protection Rated power ≤10KW (including welding machine) |

| 5 | Compressed air | 0.4-0.6MP (clean water after dewatering, no oil, filtration, pressure stabilization), use flow rate is about 300L / min |

| 6 | Production efficiency | ≥100PCS/min |

| 7 | The product qualification rate | 99% (except for the original material and human operation) |

| 8 | Main accessories | Cylinder: AirTAC Screw guide rail: HIWIN / TBI PLC: Mitsubishi or Xinjie |

| 9 | Operating environment | General workshop environment is acceptable (no corrosive odor, no dust) |

Item | Material | Specification | Coil outer diameter | Coil inner diameter |

| 1 |

Outer non-woven fabric |

200mm wide roll material |

Recommended less than 600mm |

greater than 65mm |

| 2 |

Inner layer non-woven fabric |

190mm wide roll material |

Recommended less than 600mm |

greater than 65mm |

| 3 |

Melt tape |

175mm wide roll material |

Recommended less than 600mm |

greater than 65mm |

| 4 | Nose bridge strip | 3.0mm wide roll material |

Recommended less than 400mm |

greater than 65mm |

| 5 | ear straps | 2.8mm round coil |