jiangsu jzer Automation Technology Co.,Ltd. |

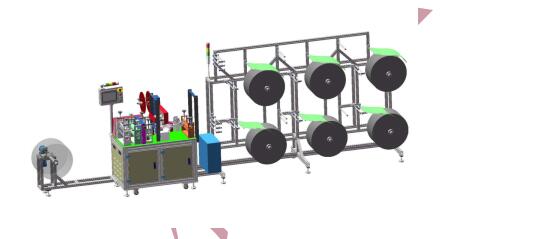

Open Design KN95 Face Mask Making Machine With Man - Machine Combination

This KN95 face mask machine is a semi-automatic KN95 face mask production line. The production line consists of a material rack, a mask film machine, an earloop welding machine and a edge banding machine.

Semi-automatic Film machine introduction

Product introduction

The equipment solves the defects of the current fully automatic line, which is difficult to operate and has a high defect rate. The equipment only needs 1 person, using the touch screen method, manual and automatic switching. Automatically built nose bridge, knurling, rolling cutting are achieved

Product Features

1. Adopt open design, good window.

2. Man-machine combination, debugging and easy maintenance.

3. Easy to operate, low cost, strong and durable.

technical parameter

| No. | Name | Parameter |

| 1 | Type | 2AT.JZKZHRDBZD-A |

| 2 | Size | 370 (length) * 80 (width) * 150 (height) |

| 3 | Weight | Total equipment weight ≤ 200KG Ground load 200KG / ㎡ |

| 4 | Working power supply | 220VAC ± 5% 50HZ grounding protection Rated power ≤10KW (including welding machine) |

| 5 | Compressed air | 0.4-0.6MP (clean water after dehydration, no oil, filtration, pressure stabilization), use flow rate is about 300L / min) |

| 6 | Production efficiency | 20-40PCS/min |

| 7 | product qualification rate | 99% (except for the original material and human operation) |

| 8 | Main accessories | Cylinder: AirTAC Screw guide rail: HIWIN / TBI PLC: Mitsubishi or Xinjie |

| 9 | Operating environment | General workshop environment is acceptable (no corrosive odor, no dust) |

Semi-automatic earloop welding machine introduction

Product introduction:

This equipment solves the defects of the current fully automatic line, difficult operation, high defect rate, etc., only one person is required in the equipment, using automatic induction and manual button type, the equipment automatically cuts the ear strap line, automatic alignment, automatic welding, and quickly reaches product quality demand.

product Features

1. Use open + closed design, good window. High safety, reduce work injury

2. Man-machine combination, debugging and easy maintenance.

3. Easy to operate, low cost, strong and durable.

technical parameter

| No. | Name | Parameter |

| 1 | Type | 2AT.JZKZHRDBZD-A |

| 2 | Size | 700 (length) * 600 (width) * 1500 (height) |

| 3 | Weight | Total equipment weight ≤200KG Ground load 200KG / ㎡ |

| 4 | Working power supply | 220VAC ± 5% 50HZ grounding protection Rated power ≤10KW (including welding machine) |

| 5 | Compressed air | 0.4-0.6MP (clean water after dehydration, no oil, filtration, pressure stabilization), use flow rate is about 300L / min) |

| 6 | Production efficiency | 20-40PCS/min |

| 7 | product qualification rate | 99% (except for the original material and human operation) |

| 8 | Main accessories | Cylinder: AirTAC Screw guide rail: HIWIN / TBI PLC: Mitsubishi or Xinjie |

| 9 | Operating environment | General workshop environment is acceptable (no corrosive odor, no dust) |

Semi-automatic V-shaped edge banding machine

This equipment solves the defects of the current fully automatic line, difficult to operate, high defect rate, etc., only one person is required to use the equipment, the foot switch type is adopted, the equipment automatically depresses the ultrasonic wave, the manual alignment is accurate, convenient, automatic welding, quickly meet the product quality requirements .

Product Features

1. Adopt open design, good window.

2. Man-machine combination, debugging and easy maintenance.

3. Easy to operate, low cost, strong and durable.

| No. | Name | Parameter |

| 1 | Type | 2AT.JZKZHRDBZD-A |

| 2 | Size | 700 (length) * 600 (width) * 1500 (height) |

| 3 | Weight | Total equipment weight ≤200KG Ground load 200KG / ㎡ |

| 4 | Working power supply | 220VAC ± 5% 50HZ grounding protection Rated power ≤10KW (including welding machine) |

| 5 | Compressed air | 0.4-0.6MP (clean water after dehydration, no oil, filtration, pressure stabilization), use flow rate is about 300L / min) |

| 6 | Production efficiency | 20-40PCS/min |

| 7 | product qualification rate | 99% (except for the original material and human operation) |

| 8 | Main accessories | Cylinder: AirTAC Screw guide rail: HIWIN / TBI PLC: Mitsubishi or Xinjie |

| 9 | Operating environment | General workshop environment is acceptable (no corrosive odor, no dust) |

1. Components:

| Product name | Semi-automatic film machine | Semi-automatic earloop welding machine | Semi-automatic V-shaped edge banding machine |

| Quantity | 1 set | 1 set | 1 set |

1, Semi-automatic Film machine

2, Semi-automatic earloop welding machine

3, Semi-automatic V-shaped edge banding machine