Wujiang Chengrong Textile Weaving Machine Factory |

|

Verified Suppliers

|

|

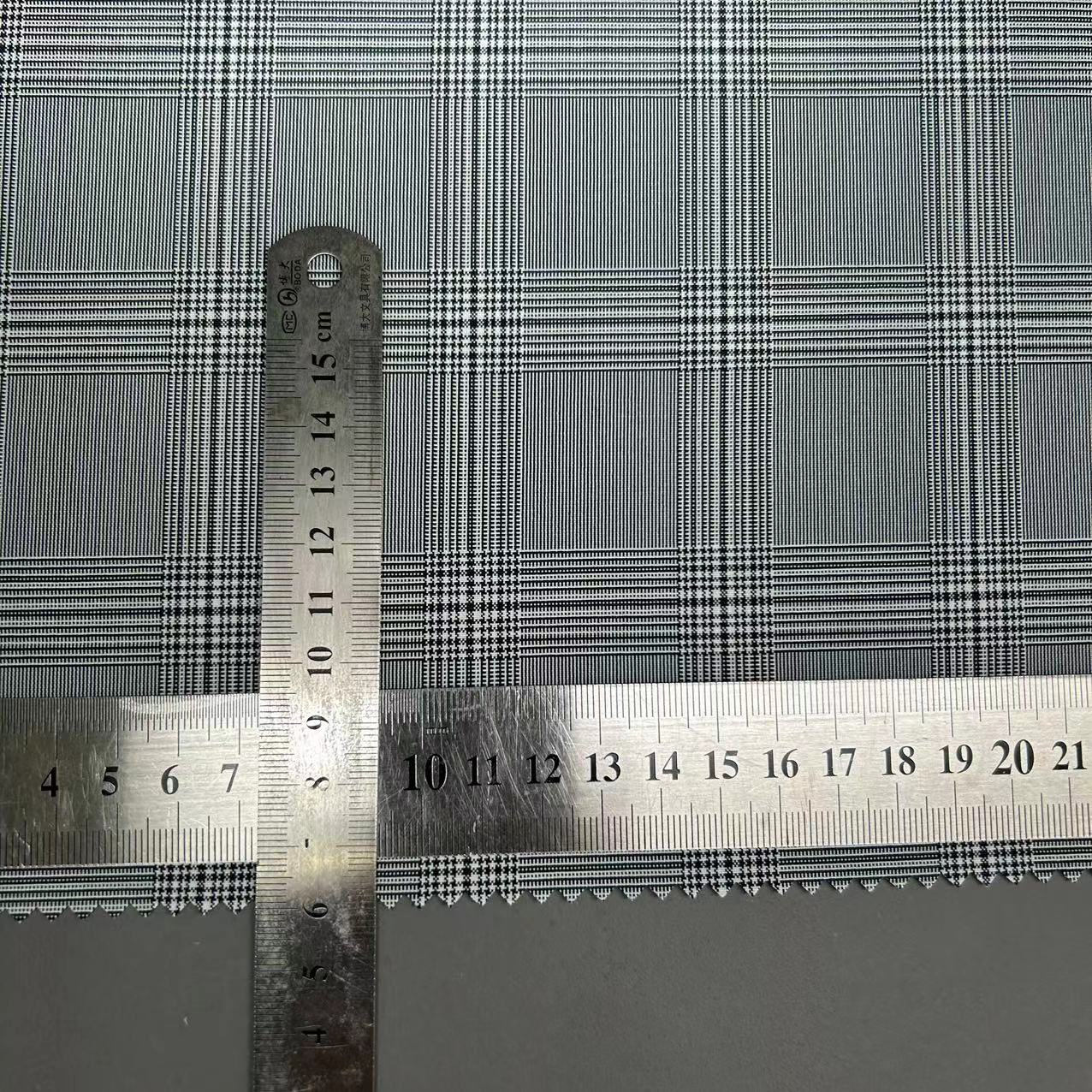

CR-15 Black And White Cationic Polyester Four-Way Stretch Grid

Fabric.200D+200D+40D*2,172GSM,97%Polyester 3%Spandex

1 . Descriptions:

Black and white cationic polyester four-way stretch grid fabric achieves a three-dimensional dual-color effect through cationic dyeing. The cationic dyes selectively color the polyester fibers, while the polyester remains uncolored. This results in a striking dual-color appearance with a sense of depth. The fabric's four-way stretch capability allows for comfortable movement, making it suitable for a variety of applications such as sportswear, activewear, and other garments that require both style and flexibility.

2.Specifications:

| Name: | Black and white cationic polyester four-way stretch grid fabric. |

| Yarn count: | 200D+200D+40D*200D+200D+40D |

| Material | 97%Polyester 3%Spandex |

| Weight: | 172GSM |

| Width | 57"58" |

| Color: | Can be dyed or printed. |

| Style: | Jacquard |

3 . Features:

When dyeing with cationic dyes and polyester, there are several important considerations regarding temperature, process, and precautions. Here's a detailed explanation in English:

1.Temperature: The dyeing temperature for cationic dyes on polyester typically ranges from 120°C to 130°C (248°F to 266°F). However, it is crucial to follow the specific dye manufacturer's instructions as the recommended temperature may vary. Maintaining the correct dyeing temperature is essential for achieving proper dye absorption and color fastness.

2.Process: Here are the key steps to consider during the dyeing process:

a. Preparation: Pre-treat the fabric by scouring and washing to remove any impurities, oils, or sizing agents that could interfere with dye absorption.

b. Dye Solution Preparation: Dissolve the cationic dyes in water, following the manufacturer's recommended dye-to-water ratio and any additional instructions for the specific dye being used.

c. Dye Bath Preparation: Fill a dye bath with water at the desired temperature, usually around 60°C to 70°C (140°F to 158°F). Add the dissolved cationic dye solution to the bath, ensuring proper dispersion.

d. Dyeing: Immerse the fabric into the dye bath, ensuring sufficient agitation to promote uniform dye penetration. Maintain the dyeing temperature within the recommended range, and monitor the dyeing time according to the dye manufacturer's instructions.

e. After-treatment: Once the desired color is achieved, rinse the fabric thoroughly to remove excess dye. Follow this with additional treatments such as a fixing agent or conditioner, if recommended by the dye manufacturer, to enhance color fastness and improve fabric properties.

3.Precautions: Consider the following precautions during the dyeing process:

a. Safety: Handle cationic dyes and dyeing chemicals with proper precautions, including wearing protective clothing, gloves, and eyewear. Follow safety guidelines and local regulations for the handling, storage, and disposal of chemicals.

b. Testing: Conduct dyeing trials on small fabric samples to determine the optimal dyeing conditions, color intensity, and colorfastness before proceeding with large-scale production.

c. Equipment and Material Compatibility: Ensure that dyeing equipment, such as dyeing machines or vessels, is suitable for working with cationic dyes and polyester. Also, verify that the fabric is compatible with the dyeing process and can withstand the required temperatures without adverse effects.

d. Dyeing Uniformity: Promote even dye absorption and color uniformity by properly agitating the dye bath, ensuring adequate fabric movement, and avoiding overcrowding the dyeing equipment.

e. Environmental Considerations: Adhere to eco-friendly practices by properly treating and disposing of dyeing wastewater according to local regulations. Implement measures to minimize water and energy consumption during the dyeing process.

By carefully considering temperature, process, and precautions, you can achieve successful dyeing results with cationic dyes and polyester, ensuring vibrant colors and excellent colorfastness.

4.More pictures: