Ningbo Qiming Machinery Manufacturing Co., Ltd. |

|

Verified Suppliers

|

|

Multi-layer Multi-cavity Extrusion Blow Moulding MP70FS-4 IML In mold labeling for food packing bottle

Introduction:

MP70FS IML is specifically designed for making bottles from 600ml up to maximum 4L. It is hydraulic driven with accrate eletrical control system. MP70FS IML has single stations to increase the production efficiency. Also, it has variety of choice of die heads. With more than 10 years of success in the market, MP70FS IML is updated to be one of the most reliable and popular model in the world.

Advantages:

CLAMPING SYSTEM: HIGHLY DEVELOPED TOGGLE CLAMPING SYSTEM

MP-F Toggle series employs direct-acting clamping system transferring the forces directly to the middle of both of the platens. And it adopts high precision linear guides to provide accurate platen and station movements.

ENERGY SAVING: HIGH STANDARD OF ENERGY SAVING SYSTEM

MP70FS IML is equipped with high standard of energy saving driving systems. All extrusion and hyraulic motors are in IE3/4 energy level. Also, servo energy saving feature can be easily applied.

Machine can keep normal service life only under good conditions.

1.Abide by all notes in this manual strictly.

2. Pay attention to surface cleaning.

3. Check all fasten conponents. Tighten them if they are found loose.

4. Keep enough lubricating of moving surfaces and choose correct lubrication.

5. Rated pressures of all action oil cylinders are 14Mpa. Be careful during

| MP70FS | ||||

| Single station blow molder with horizontal linear mould shuttle | ||||

| Length: | 3600mm | |||

| Width: | 2200mm | |||

| Height | 2360mm | |||

| Key Data | MP70FS |  | ||

| mm | ||||

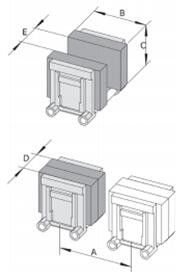

| Linear mould stroke | A | 520 | ||

| Mould Width | B | 500 | ||

| Mould Length | C | 400 | ||

| Mould Thickness | D | 250 | ||

| Opening Stroke | E | 350 | ||

| Platen daylight | D+E | 600 | ||

| Clamping Force | 75kN | |||

| Dry Cycle | 7 sec. | |||

| Centre Distance | 1x2 fold | 160 | ||

| 1x3 fold | 120 | |||

| 1x4 fold | 100 | |||

| 1x6 fold | 60 | |||

| Extruder | φ70 | φ75 | φ80 | |

| Screw Speed | r/min | 0~65 | 0~65 | 0~65 |

| Screw Diameter | mm | 70 | 75 | 80 |

| Screw L/D Ratio | L/D | 24 | 24 | 24 |

| Energy Requirements | ||||

| Extruder Inverter Power | kW | 18.5 | 22 | 30 |

| Extruder Moter Power | kW | 18.5 | 22 | 30 |

| Srew Heating Power | kW | 12.7 | 14.4 | 15.85 |

| Fan Power | kW | 0.14X2 | 0.14X2 | 0.14X2 |

| Oil pump Motor Power | kW | 15 | 15 | 15 |

| Total Power of Machine | kW | 49.14 | 54.34 | 63.79 |

| Air Requirement approx | m3/min | 1.2 | 1.2 | 1.2 |

| Air Working Pressure | Mpa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Cooling Requirements | ||||

| Consumption Cooling Water | L/min | 40 | 40 | 40 |