Weifang Kaide Plastics Machinery Co., Ltd |

|

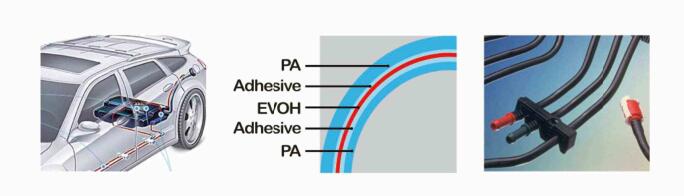

Multilayer Automobile PA Nylon Oil Tube Extrusion Machine

Automotive Fuel Tube Making Machine

PA multilayer composite pipe of automotive fuel system is

internationally widely used in car fuel oil system which features a

kind of portable, high performance and environmental protection

line products.

PA automotive fuel tubes have different layer structure, like two

layer, 3 layer and 5 layer with oxygen barrier. its outside

diameter has 6 mm, 8 mm, 10 mm and other different specifications.

PA multilayer oxygen barrier pipe can effectively reduce the

automobile emission pollution to the environment, and meet the

higher environmental requirements. At the same time multilayer

composite pipe possesses excellent resistance to penetration

performance, can satisfy the EU-III standards.

.

Multilayer Pipe Structure:

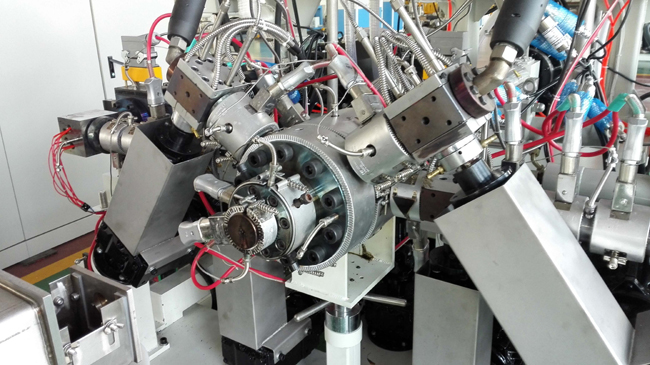

TECHNICAL DATA

| lINE Model | Screw diameter | Production Scope | Production Speed |

|---|---|---|---|

| KDFPA-45 | 45/45/30mm | 6-20mm | 40m/min |

| KDFPA-65 | 65/45/30mm | 6-20mm | 80m/min |

PA fuel tube sizes:

| No. | Pipe Size (mm) | Outer diameter (mm) | Thickness (mm) |

| 1 | Ø4×0.75 | Ø4±0.1 | 0.75±0.1 |

| 2 | Ø6×1 | Ø6±0.1 | 1±0.1 |

| 3 | Ø8×1 | Ø8±0.1 | 1±0.1 |

| 4 | Ø10×1 | Ø10±0.1 | 1±0.1 |

| 5 | Ø12×1.25 | Ø12±0.1 | 1.25±0.1 |

| 6 | Ø14×1.5 | Ø14±0.1 | 1.5±0.1 |

MULTILAYER AUTOMOBILE FUEL PIPE MACHINE

MORE INFORMATION NEEDED,

PLS CONTACT US RIGHT NOW!!