BOTO GROUP LTD |

|

Verified Suppliers

|

|

Description:

Xenon lamp weatherproof test chamber equipment can be used for the selection of new materials, improvement of existing materials or assessment of changes in the durability of materials after changes in composition. The device can well simulate the changes of materials exposed to sunlight in different environmental conditions. The equipment tests the light resistance of materials by exposing them to ultraviolet (UV), visible and infrared light. It uses filtered xenon arc lamps to produce a full spectrum of sunlight with maximum compatibility with sunlight. Xenon arc lamps with proper filtration treatment are the best way to test the sensitivity of products to ultraviolet and visible light in the longer wavelength range of direct illumination or sunlight through glass. When you expose your product to direct sunlight outside, it experiences maximum light intensity for only a few hours a day. Even so, the worst exposure occurs only during the hottest weeks of summer.

Scope:

Applicable to light fastness and aging test of textiles, paints, dyes, coatings, rubber, plastics, wood flooring and paper and other materials, with rain, revolution, rotation and spray resistance and other weather resistance.

Standards:

GB / T 8427, ISO 105-B02, GB / T 8430, ISO 105-B04, GB / T 14576, AATCC TM 16, GB / T 15102, GB / T 15104 and so on.

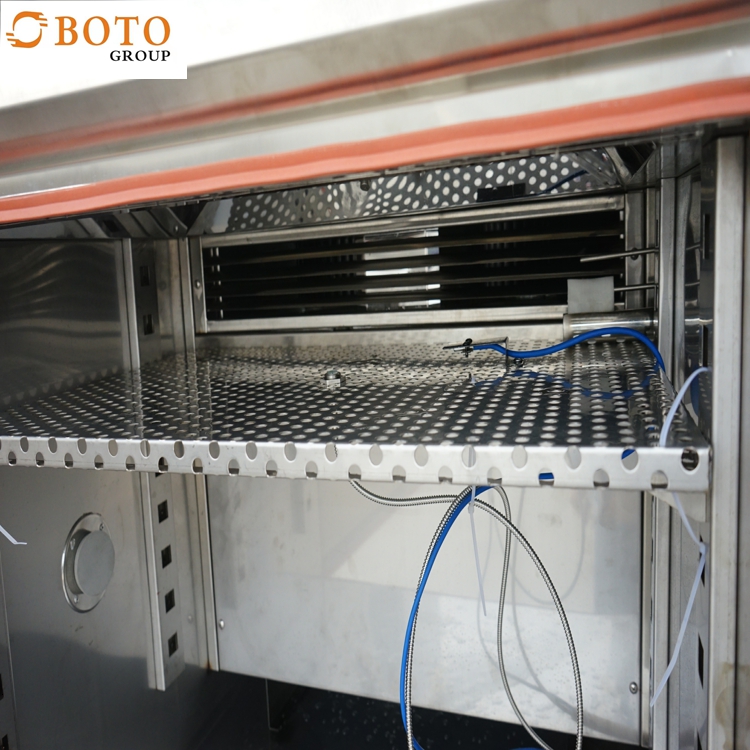

Box structure:

External box material: All of them are made of high quality (t=1.2mm) A3 steel plate CNC machine tool processing, shell surface is sprayed with plastic treatment, more bright and clean, beautiful

Material: imported advanced stainless steel (SUS304)

Insulation material: rigid polyurethane foam + glass fiber

Temperature and humidity circulation system: special air conditioning low noise long shaft fan motor, high and low temperature resistant stainless steel multi-wing impeller, in order to achieve the intensity convection vertical diffusion cycle

Test placement: Xenon lamp with built-in guide rail, articles flat. The hub type xenon lamp uses a fixture to fix the sample, and the sample is a flake specification item.

Sealing: A double-layer high temperature and high tension sealing strip is used between the door and the box to ensure the airtight of the test area

productive process:

It has the following performance characteristics:

1. Adopt full-spectrum xenon lamp luminescent tube;

2, a variety of filter system for choice;

3, rain spraying function;

4. Relative humidity control.

5, test chamber air temperature control system;

Model | B-XD-120 | B-XD-225 | B-XD-408 | B-XD-800 | |

Internal Dim(W*H*D) | 45x60x45 | 50x75x60 | 60x85x80 | 100x100x80 | |

| External Dim(W*H*D) | 107x145x68 | 120x164x92 | 122x169x112 | 162x184x112 | |

| Temperature range | RT+10℃~70℃ | ||||

| Humidity range | 50%~90%RH | ||||

| Radiation intensity of xenon lamp | 550W/m² | ||||

| Spectral wavelength region | 290nm-800nm | ||||

| rainfall time | 0-9999/min | ||||

| Total power xenon lamp | 2KW/6KW | ||||

| type of cooling | forced air cooling/water-cooling | ||||

| Interior | SUS#304Stainless steel plate | ||||

| External material | Coating or SUS#304Stainless steel plate | ||||

Power Source | AV:220V/380V 50/60Hz | ||||

Produce Making Details:

Our company:

Packing/Shipping:

During the whole business process, we offer Consultative Selling service.

1)Customer inquiry process:

Discussing testing requirements and technic details, suggested suitable products to customer to confirm. Then quote most suitable price according to customer requirements.

2)Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photoes to show the proucts appearance. Then, confirm the final solution and confirm final price with customer.

3)Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photoes to show production process.

After finish production, offer photoes to customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing.

Deliver the products in confirmed shipping time and inform customer.

4)Installation and after sale service:

Defines installing those products in the field and providing after-sales support.