Guangzhou Ailusi Machinery Co., Ltd. |

|

Verified Suppliers

|

|

The Cosmetic Liquid Mixer Detergent Heated Mixing Reactor Mixing Tank with Agitator Blender is a versatile and essential equipment for the cosmetic and detergent manufacturing industries. This high-quality mixing reactor is designed to efficiently blend various cosmetic and detergent formulations, ensuring consistent product quality.

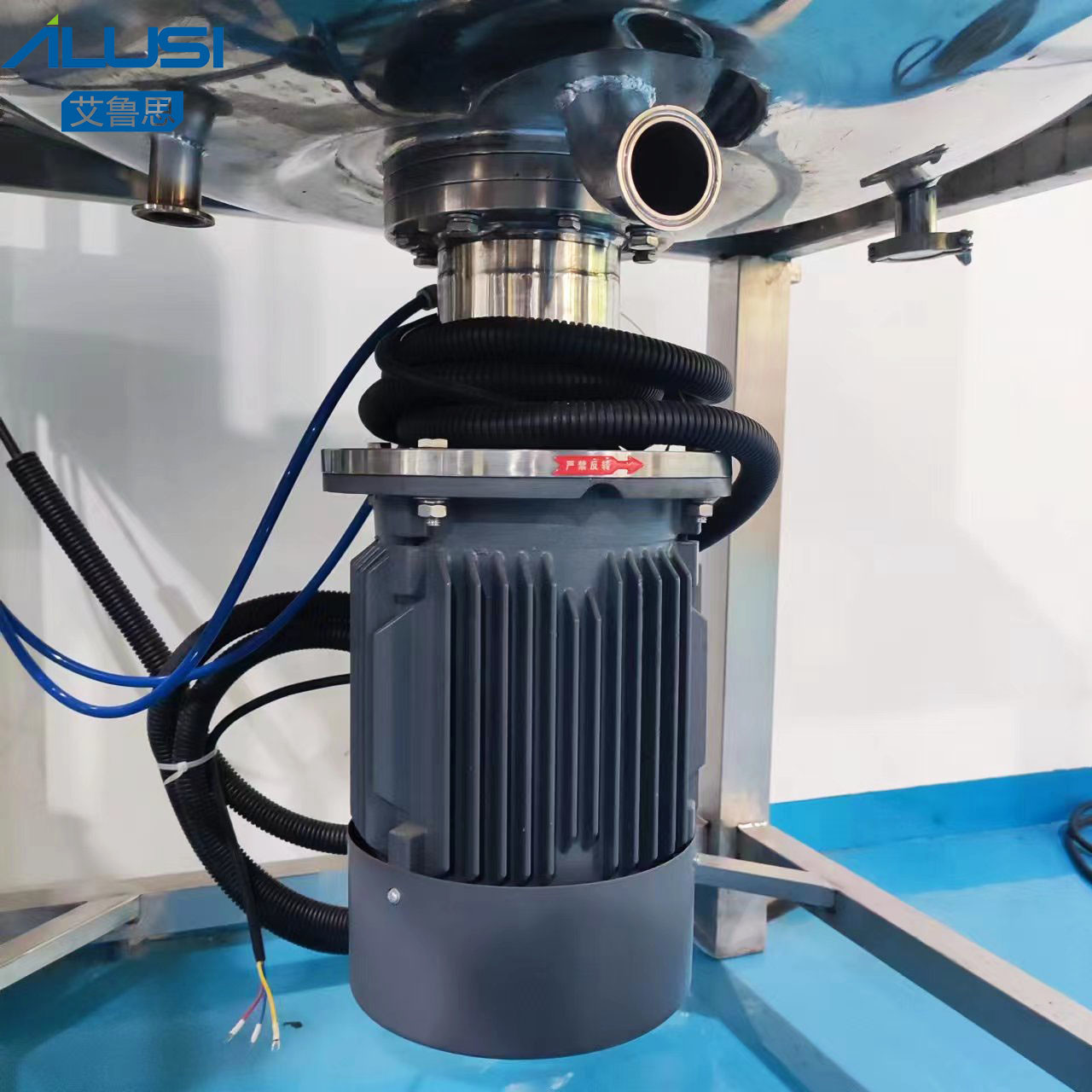

Equipped with a powerful agitator and heating capabilities, it facilitates thorough mixing and uniform temperature control, critical for the production of cosmetics and detergents. The tank's durable construction and agitator design enable it to handle a wide range of viscosities and ingredients, making it suitable for various formulations.

With its precise control and reliable performance, this mixing reactor enhances productivity, reduces production time, and ensures the homogeneity of your cosmetic and detergent products. It is a must-have tool for manufacturers looking to maintain product quality and efficiency in their production processes.

FEATURES

| Model | AHM-300 | Working capacity | 300L |

| Heating method | Steam/electric | Working capacity | Frame wall scraper mixing |

| Mixing motor power | 3KW | Mixing frequency | 3KW |

| Mixing Speed | 0-65rpm | Homogenizer frequency | 5.5KW |

| Bottom Homogenizer power | 5.5KW | Homogenizer type | Internal and external circulation(option) |

| Control method | Button control | Frequency converter | Delta/Panasonic/Mitsubishi |

| Electrical components | Schneider/Delixi | Tank materials | Inner layer 5mm/SUS316 Middle layer 5mm/SUS304 Outer layer 3mm/SUS304 |

PRODUCT CONFIGURATION

|  |  |

| Siemens BEIDE Motor | Reducer | Delta Frequency inverter |

|  |  |

| Stator and rotor | rotor | Materials SUS304&316L(TISCO) |

|  |  |

| Burgmann Mechanical seal | NSK Bearing | Omron temperature controller |

|  |  |

| Indicator light, Schneider | Button , Schneider | Current Transformer,Delixi |

|  |  |

| Time Relay | Breaker | AC contactor |

CERTIFICATION

MATERIALS SOURCE

Factory:

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.

FQA:

Q: How can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except

weekend and holidays). If you are very urgent to get the price,

please email us or contact us in other ways so that we can offer

you a quote.

Q: Can I buy samples placing orders?

A: Yes.Please feel free to contact us.

Q: What is your lead time?

A: It depends on the order quantity and the season you place the

order.Usually we can ship within 10-20 days for small quantity,and

about 30 days for large quantity.

Q: What is your payment term?

A: T/T,Western Union,L/C,and Paypal.This is negotiable.

Q: What is the shipping method?

A: It could be shipped by sea,by air or by express(EMS, UPS, DHL, TNT,

FEDEX and ect).