Shenzhen Adkiosk Technology Co., Ltd. |

|

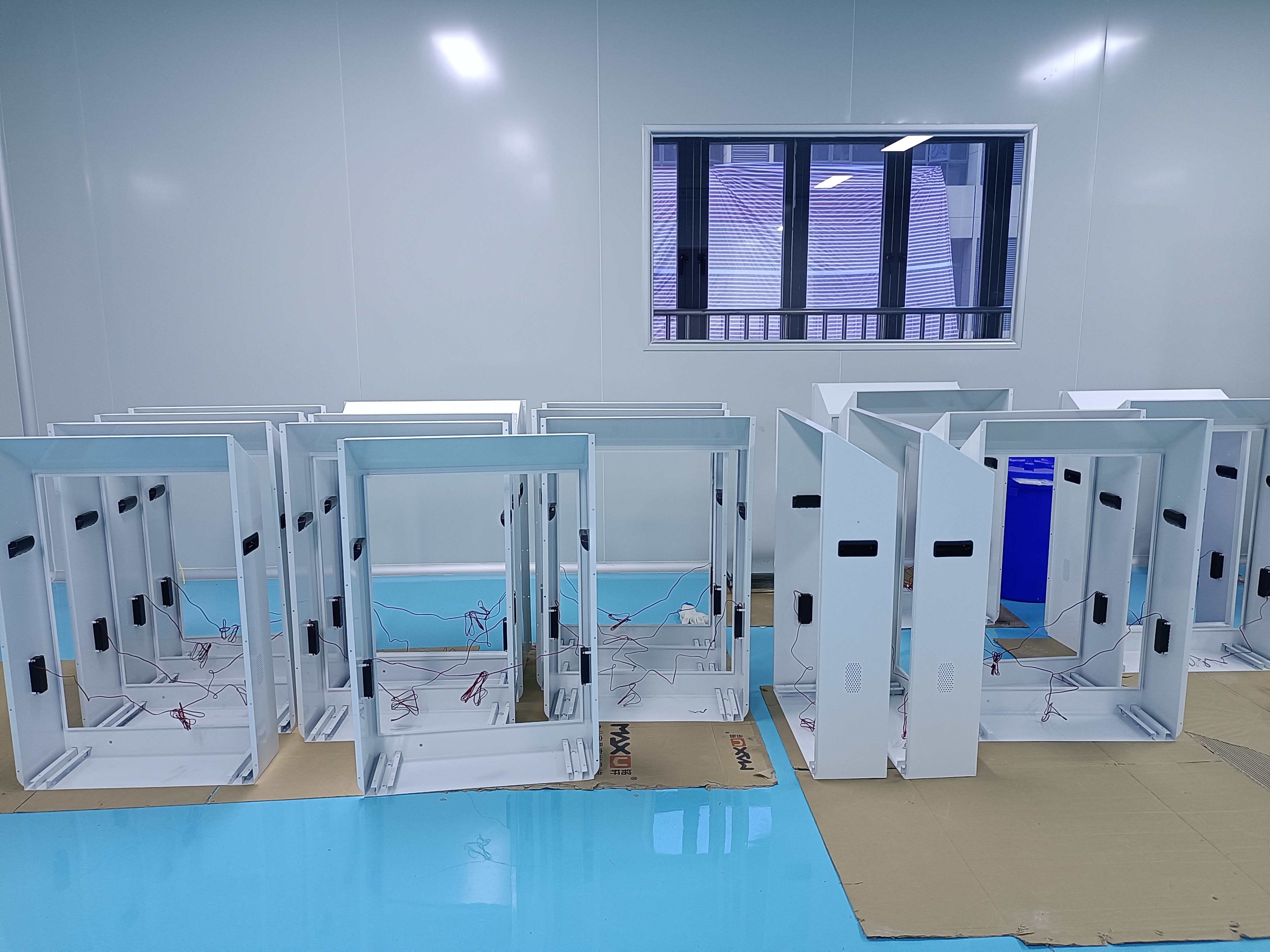

Customized Service All kinds Of Floor Standing Kiosk ODM OEM Sheet Metal Frame Fabrications

Surface Treatment Optional | ||||||

Style | As machined Smoothed Powder Coated Brushing Anodized Hardcoat Electropolished Bead Blasted Anodized Clear or Color etc. | |||||

Material Available Optional | ||||||

Combination Method | All metals All metals+Plastic (e.g aluminum, steel,nylon, ABS) All metals ( e.g aluminum, steel) Aluminum and Titanium alloys Metal+plastic (e.g aluminum, ABS) Aluminum and Titanium alloys etc. | |||||

Common problems of metal material sheet metal chassis processing

1. Expansion methods should be integrated to save raw materials and

processability.

2. Effective method of selecting gaps and edging strips, t=0.2

below 2.0, t=0.5 below 2-3, long side wrapped short side (door

frame type)

3. Effective consideration of dimensional tolerances. Dimensions:

negative difference to the end, positive difference to the end,

hole shape specifications: positive difference to the end, negative

difference to half.

4. The direction of the burr

5. Make a cross-sectional view of tooth extraction, pressure

riveting, tearing, stamping die and projection (bag) orientation.

6. Check raw materials, plate thickness and plate thickness

tolerances.

7. The processing of sheet metal chassis has a unique viewing

angle, and the bending viewing angle is semi-long (generally r=0.5)

to detect and proceed.

8. Pay attention to areas that are very easy to be mistyped

(similar and different).

9. Areas with more specifications have to be enlarged and enlarged

10. The painting area must be marked

11. The plating on the surface of the sheet metal chassis must be

symmetrical, and no suspension or bottom end should be exposed.

12. The logo should be detailed, clear, durable and reliable. The

serial number of the logo should not be lost.

13. The control panels of the sheet metal chassis should be

leveled, without deformation or distortion, and the perforations of

the cabinet doors should be symmetrical and neat.

14. The specifications should meet the requirements, and the

difference should not be too large.

Because the processing technology and raw material selection of

sheet metal chassis manufacturers are different, the quality of the

processed sheet metal chassis server cabinet chassis is also

different. Because of the different requirements, the quality of

the main box is also different. There are different types of car

chassis, but no matter how different they are, it's all for a

reason.