Chengdu Xingtongli Power Supply Equipment Co., Ltd. |

|

Verified Suppliers

|

|

AC to DC plating Rectifier 8V 1000A

Specification

| SPECIFICATIONS FOR GKD8-1000CVC | |||

| Input AC | 380V±10% | 3phase | 50/60Hz |

| Output DC | Volt | 0~8V Adjustable | |

| Current | 0~1000A Adjustable | ||

| Power | 8KW | ||

| Efficiency | >85% | ||

| output Frequency | 40KHz fixed | ||

| Protection | Short circuit protection Overheating protection Phase lack protection Input over/low voltage protection | ||

| Working Condition (Temperature) | -10℃~50℃ | Control mode | Panel control Remote control |

| Net weight | 70kg | Working mode | Constant Voltage(CV) Constant Current(CC) |

| Dimension(mm) | 665*490*270mm | Cooling way | air cooling |

Features

Electro plating power supply provide power supply to a variety of plating bath. Plating can be divided into direct current plating, cycle pole reverse plating, and pulse electroplating etc.. Early plating power supply used by AC motors – DC generator units, since the 1980s has gradually been replaced of power electronic devices composed plating power supply.

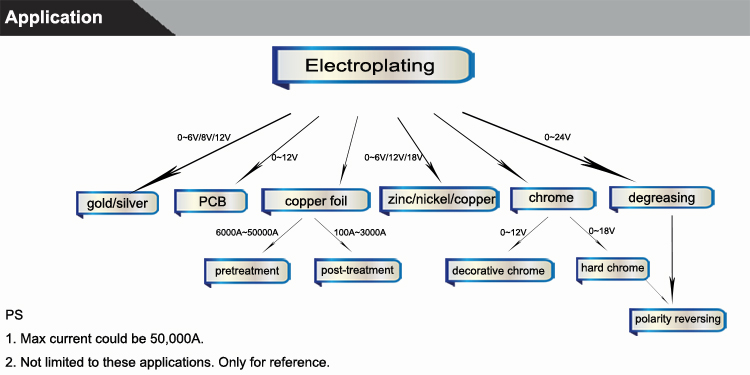

AC to DC plating rectifier application:

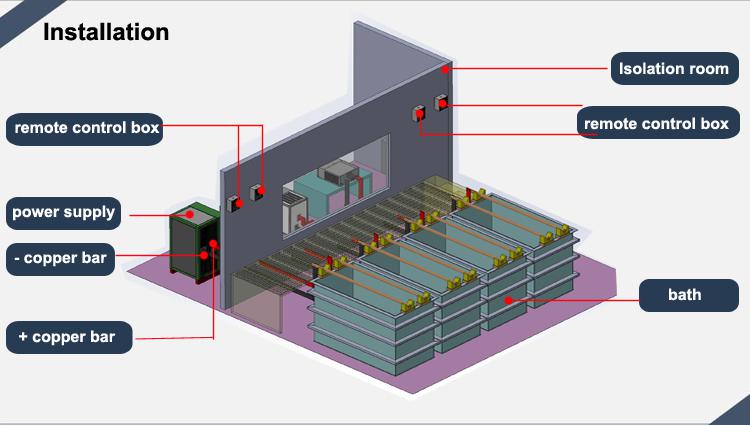

How to install rectifier

This is installation way for remote control rectifier. Not only

this way.

1. To connect copper bar with bath/tank

2. To ensure power supply/rectifier is grounded

3. To ensure there is enough water for water cooling type power

supply/rectifier

4. We advice that all rectifiers should be isolated to increase of

its life.

Electroplating technology

As electronic components become increasingly smaller, the use of electroplating to manufacture the components and interconnects between these devices has become significantly more important. Historically, a simple powerstat was used to control the rectifier output.

As the power requirements changed and the plating requirements continued to be more sophisticated, electroplaters started to specify outputs with a ripple of less than 5%, so chokes and capacitors were used to smooth the output. Now switching power supplies are becoming the industry standard because of their small footprint, good regulation, and low ripple.

Plating is essentially a molecule-by-molecule process where soluble metal ions dissolved in water pick up electrons from the rectifier at the cathode. The electrons convert the metal ions back into the solid metal. For the metal ions to be reduced to the metal, the predominant flow of electrons has to be into the workpiece, which is at the cathode.

A power supply used for plating is considered a dc supply as long as more electrons flow into the piece being plated than are removed from it. If more electrons are removed from the workpiece than flow into it, the workpiece either dissolves or anodizes depending on the type of metal.