Chengdu Xingtongli Power Supply Equipment Co., Ltd. |

|

Verified Suppliers

|

|

DC Power source for tank electrolysis with air cooling remote control

Description of high frequency electrolytic power supply:

1. The structure of single main cabinet or double main cabinet plus control cabinet can be configured according to the user's requirements.

2. When the DC output current is ≥ 10kA, the whole circuit in parallel with the reverse rectifier circuit is adopted, which greatly reduces the eddy current loss and improves the efficiency of the electrolytic power supply.

3. The control mode can be divided into open-loop (manual) and closed-loop (automatic) according to the production process requirements, and can be converted to each other. The output phase number of DC current can be divided into 6, 1224, 36 and 48 phase pulse rectifiers according to the harmonic current standard, eliminating the pollution of power rectifiers 3, 5 and 7 on the power grid.

4. This series of electrolytic power supply has over-current, over-voltage, short circuit, branch, under phase, high water temperature, water pressure, oil temperature and high / low, high oil pressure protection, fully integrated control circuit.

5. The main control board adopts high anti-interference and high-power digital circuit trigger system, which has strong anti-interference ability. It has the advantages of high control accuracy, good stability and reliable operation.

6. The cabinet adopts cutting magnetic link to reduce eddy current loss. The cabinet adopts overall plastic spraying.

7. Control mode: integrated analog control and computer control.

Specification

| SPECIFICATIONS FOR GKD48-100CVC | |||

| Input AC | 380V±10% | 1phase | 50/60Hz |

| Output DC | Volt | 0~48V Adjustable | |

| Current | 0~100A Adjustable | ||

| Power | 4.8KW | ||

| Efficiency | >85% | ||

| output Frequency | 40KHz fixed | ||

| Protection | Short circuit protection Overheating protection Phase lack protection Input over/low voltage protection | ||

| Working Condition (Temperature) | -10℃~50℃ | Control mode | Panel control Remote control |

| Net weight | 18kg | Working mode | Constant Voltage(CV) Constant Current(CC) |

| Dimension(mm) | 520*395*165mm | Cooling way | water cooling |

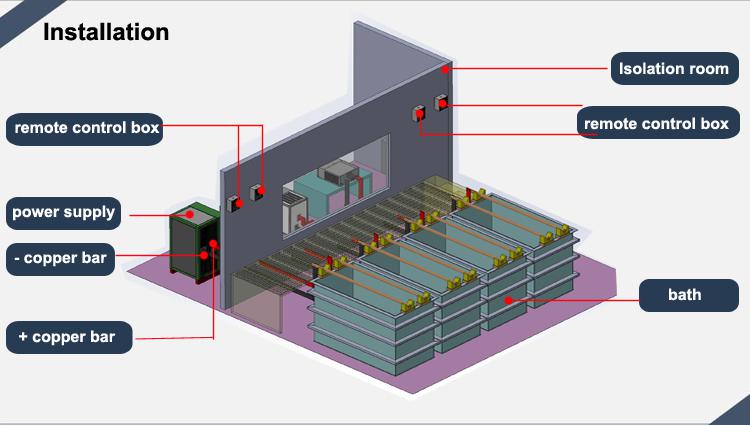

How to install rectifier

This is installation way for remote control rectifier. Not only

this way.

1. To connect copper bar with bath/tank

2. To ensure power supply/rectifier is grounded

3. To ensure there is enough water for water cooling type power

supply/rectifier

4. We advice that all rectifiers should be isolated to increase of

its life.

1. Principle of electrolysis

① Concept: The process of causing current to pass through the electrolyte solution to cause redox reactions at the cathode and anode is called electrolysis;

The device that can be converted into chemical energy is called an electrolytic cell.

②Formation conditions of electrolytic cell: the electrode connected to the positive electrode of the power supply is the anode, and the electrode connected to the negative electrode of the power supply is the negative electrode

Poles; both poles are immersed in the same electrolyte solution at the same time; forming a closed circuit, so that it can form a working electrolytic cell.

③ Bipolar reaction: the anode loses electron oxidation reaction, and the cathode gets electron reduction reaction; the electron flow method

Starting from the negative electrode of the electrode, through the cathode of the electrolytic cell, and then from the anode of the electrolytic cell back to the positive electrode of the power supply.

2. Application of electrolysis principle

(1) Electroplating: The process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. When plating,

The coated metal serves as the anode, the plated object serves as the cathode, and the electrolyte solution containing the coated metal ions serves as the plating solution. Direct current for electroplating

For power supply.

(2) Electric smelting: electrolytic molten electrolyte can be refined into active metals. Such as potassium, sodium, calcium, magnesium, aluminum and other metals. When the electricity

When flowing through molten metal chloride or oxide, the negative electrode of the current is the strongest "reducing agent", and the metal cation will be in the negative

Extremely reduced reaction and precipitation.