Chengdu Xingtongli Power Supply Equipment Co., Ltd. |

|

Verified Suppliers

|

|

60v 500a Anodizing Power Supply

Aluminum anodizing characteristics:

The process of using aluminum or aluminum alloy products as the anode, placing it in an electrolyte solution for energization treatment, and forming an aluminum oxide film on the surface by electrolysis is called anodization of aluminum and aluminum alloys. After anodizing, an aluminum oxide film can be formed on the surface of a few microns—a few hundred microns. Compared with the natural oxide film of aluminum alloy, its corrosion resistance, abrasion resistance and decoration are all significantly improved and improved.

the principle of aluminum anodization is essentially the principle

of water electrolysis. When the current passes, the following

reactions will occur:

On the cathode, H2 is released according to the following reaction:

2H + + 2e → H2

On the anode, 4OH-4e → 2H2O + O2, the precipitated oxygen is not

only molecular oxygen (O2), but also atomic oxygen (O), and ionic

oxygen (O-2), usually expressed as molecular oxygen in the reaction

.

The aluminum as the anode is oxidized by the oxygen deposited on it

to form a anhydrous Al2O3 film: 2AI + 3[O] = AI2O3 + 1675.7KJ It

should be pointed out that not all generated oxygen interacts with

aluminum, and part of it is precipitated in gaseous form .

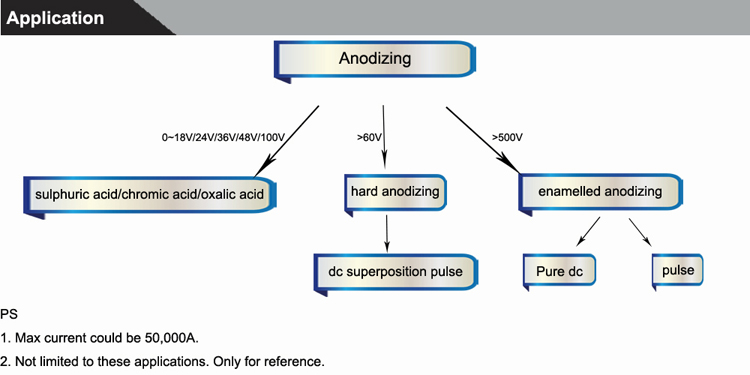

Types of anodization Anodization has long been widely used in

industry. There are many ways to name different names. There are

several classification methods:

According to the current type, there are: direct current anodizing,

alternating current anodizing, and shortening the production time

to the required thickness. The film layer is thick, uniform and

dense, and the pulse current anodizing with significantly improved

corrosion resistance.

According to the electrolyte, there are: sulfuric acid, oxalic

acid, chromic acid, mixed acid and natural coloring anodizing with

organic sulfonic acid solution.

According to the nature of the film layer, there are: anodization

of ordinary film, hard film (thick film), porcelain film, bright

modification layer, semiconductor barrier layer, etc.

The direct current sulfuric acid anodic oxidation method is most

commonly used because it has anodizing treatment suitable for

aluminum and most aluminum alloys; the film is thick, hard and

wear-resistant, and it can obtain better corrosion resistance after

sealing the hole; The film is colorless and transparent, with

strong adsorption capacity and easy to color; the processing

voltage is low and the power consumption is low; the processing

process does not need to change the voltage cycle, which is

conducive to continuous production and practical operation

automation; sulfuric acid is less harmful to human body than

chromic acid and has a wide supply , Low price and other

advantages.

In the past decade, my country's construction industry has

gradually used aluminum doors and windows and other decorative

aluminum materials, and their surface treatment production lines

have adopted this method.

Specification

| SPECIFICATIONS FOR GKD60-500CVC | |||

| Input AC | 380V±10% | 3 phase | 50/60Hz |

| Output DC | Volt | 0~60V Adjustable | |

| Current | 0~500A Adjustable | ||

| Power | 30KW | ||

| Efficiency | >85% | ||

| output Frequency | 40KHz fixed | ||

| Protection | Short circuit protection Overheating protection Phase lack protection Input over/low voltage protection | ||

| Working Condition (Temperature) | -10℃~50℃ | Control mode | Panel control Remote control |

| Net weight | 90kg | Working mode | Constant Voltage(CV) Constant Current(CC) |

| Dimension(mm) | 750*560*780mm | Cooling way | Air cooling |

Characteristics of aluminum anodized dc rectifier:

It has the advantages of small size, light weight, high efficiency and high control precision.

The pulse width modulation power supply introduces the international advanced technology, adopts the international brand IGBT power module;

Perfect protection function, with stable voltage and stable current working mode, and with filtering, overvoltage, overheat, short circuit, missing phase protection function and soft start function.

The power supply adopts special design control system, and the internal structure is acid and alkali resistant, which greatly improves the service life of the product.

A. Digital timing system;

B. Ampere hour meter;

C. Standard interface;

D. Control signal interface.

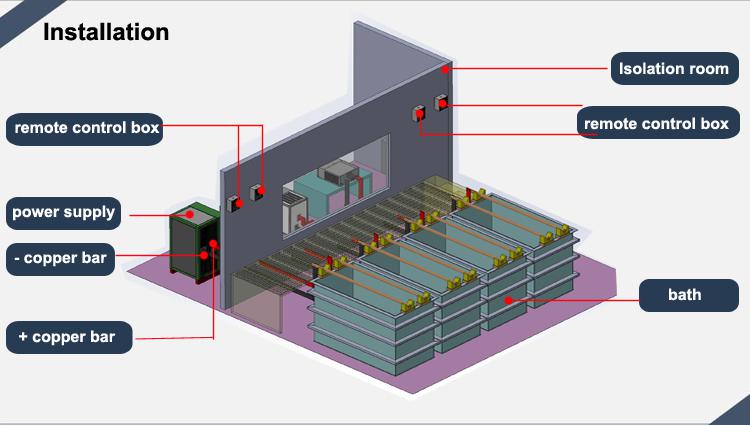

How to install rectifier

This is installation way for remote control rectifier. Not only

this way.

1. To connect copper bar with bath/tank

2. To ensure power supply/rectifier is grounded

3. To ensure there is enough water for water cooling type power

supply/rectifier

4. We advice that all rectifiers should be isolated to increase of

its life.