Chengdu Xingtongli Power Supply Equipment Co., Ltd. |

|

Verified Suppliers

|

|

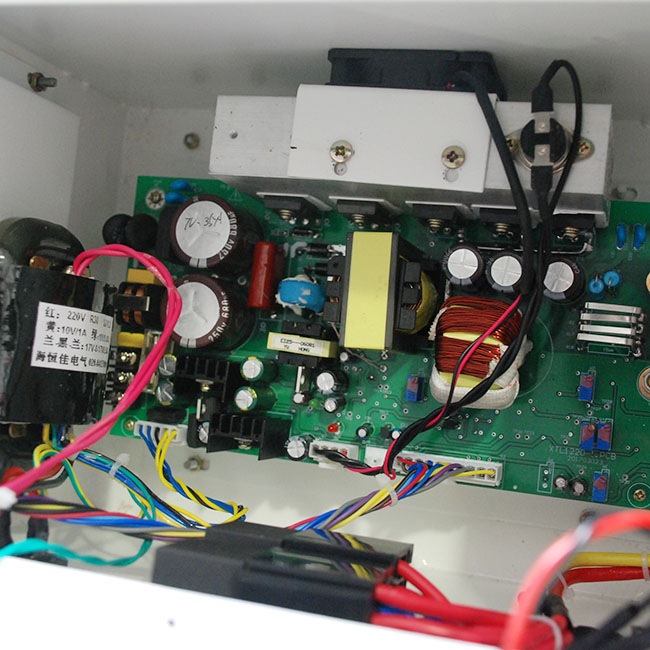

12 Volt 5Amp wall mounting Water treatment System Power Supply Specification and parameter

Description of high frequency electrolytic power:

The use of electrical dissociation, with the aid of chemical

coagulants, to remove pollutants in wastewater or to convert toxic

substances into non-toxic substances is called

electro-flocculation.

The reaction principle of electro-flocculation is to use aluminum,

iron and other metals as anodes. Under the action of direct

current, the anode is eroded to produce Al, Fe and other ions.

After a series of hydrolysis, polymerization and oxidation of

ferrous iron, it develops into various hydroxyl groups. Complexes,

polynuclear hydroxyl complexes and even hydroxides cause the

colloidal impurities and suspended impurities in the wastewater to

coagulate and separate. At the same time, the charged pollutant

particles swim in the electric field and part of their charge is

neutralized by the electrode. Promote its stability.

When the wastewater is subjected to electrolytic flocculation

treatment, it not only has the function of coagulation and

precipitation of colloidal impurities and suspended impurities, but

also can remove a variety of pollutants in the water due to the

oxidation of the anode and the reduction of the cathode.

Product use

This product is widely used in wastewater treatment in printing and

dyeing, dye chemical industry, hospital, leather, electroplating

and other industries

The electrolytic method is mainly used to treat chromium-containing wastewater and ***-containing wastewater. In addition, it is also used to remove *** ions, oil and suspended matter in wastewater; it can also coagulate and adsorb dye molecules in wastewater in a colloidal or dissolved state, and redox can destroy chromophores and obtain Depigmentation effect. Experimental research on the treatment of wastewater containing phenol, cadmium, sulfur, and organic phosphorus, as well as wastewater from the food industry using electrolytic methods is also underway.

Sewage treatment power supply equipment can be widely used in the treatment of various industrial wastewater, agricultural wastewater, ***, domestic sewage, electrolytic wastewater (that is, to recover recyclable metal ions in wastewater or to process organic substances through electrolysis), etc.

specification

| input voltage | 220v 1 phase 50/60hz |

| Output voltage | 0~12v adjustable |

| Voltage stability | 0~5a adjustable |

| Current stability | ≤1% |

| Ripple factor | 1%-2% |

| efficiency | ≥90% |

| weight | 12kg |

| dimension | 270*220*88mm |

| Stabilization mode | Current stabilization/Voltage stabilization (Switchable easily) |

| Adjustment range | Voltage/Current from 0-100% continuously adjustable within rated range |

| Cooling system | Air cooling |

| Control method | local control/remote control/plc control |

| Display contents | Voltage meter/Current meter/Working/Over temp/Error, |

| Protection method | Input over-voltage/Under-voltage/Over current/Output short/Over heating self protection etc.. |

| Operating temperature | -20-50℃ |

| Ambient temperature | -30-65℃ |

| Ambient humidity | ≤90% |

Application of 12 Volt 5Amp wall mounting Water electrolytic treatment System Power Supply :

Mainly used in non-ferrous metal electrolysis: aluminum, magnesium, zinc, lead, copper, manganese and manganese dioxide; gold, silver and other metals smelting; neodymium iron boron rare earth smelting; hard alloy, diamond smelting; salt water, potassium electrolysis to produce caustic soda, potash, sodium system; fire electrical heating materials, and other types of high-power DC power supply.

| 1, Placing rectifier and keep the body stability; ensure good ventilation. |

| 2, Checking anodizing rectifier out cover if loosing. |

| 3, Connecting shell to ground to prevent static electricity. |

| 4, Conecting the AC input wire |

| 5, Connecting the DC output copper bars |

| 6, Connecting the rectifier remote control box,if local control ,skip this step |

| 7, Turn on air switch, then the fan starts to rotate and the power indicator light. |

| 8, Clockwise rotation adjustment button, voltmeter degree increases, working indicate light lighting. |

| 9, Adjust knob to maximum, then the voltmeter should indicate the rated voltage, current meter indicates the load volume accordingly. |

| 10, Disconnect the air switch, turn off the rectifier |