Chengdu Xingtongli Power Supply Equipment Co., Ltd. |

|

Verified Suppliers

|

|

HF switching Rectifier SMR 12v 400a with 380v 3 phase AC input Specification and parameter

Description of high frequency electrolytic power:

switching Rectifier SMR main circuit includes main transformer, power rectifier components and some other testing, protection devices. Power supply main transformer function is to reducing AC current/voltage to the plating technical process required voltage value. Thyristor rectifier uses frequency (50Hz/60Hz) transformer, while high-frequency switching power supplies using high frequency (10 ~ 50kHz) transformer. Detection devices include voltage meter, current transformers. Protection device is mainly used for power rectification components over-current protection. The control circuit includes a thyristor or IGBT, trigger control circuit, power soft-start circuit, over-current, over-voltage protection circuit, power phase protection circuit.

| input voltage | 380v 3 phase 50/60hz |

| Output voltage | 0~12v adjustable |

| Voltage stability | 0~400a adjustable |

| Current stability | ≤1% |

| Ripple factor | 1%-2% |

| efficiency | ≥90% |

| weight | 25kg |

| dimension | 520*395*165mm |

| Stabilization mode | Current stabilization/Voltage stabilization (Switchable easily) |

| Adjustment range | Voltage/Current from 0-100% continuously adjustable within rated range |

| Cooling system | Air cooling |

| Control method | local control/remote control/plc control |

| Display contents | Voltage meter/Current meter/Working/Over temp/Error, |

| Protection method | Input over-voltage/Under-voltage/Over current/Output short/Over heating self protection etc.. |

| Operating temperature | -20-50℃ |

| Ambient temperature | -30-65℃ |

| Ambient humidity | ≤90% |

Cabinet: HF switching Rectifier SMR with timer adopts magnetic cut links, reduce eddy current losses, and cabinet as a whole spray painting | Structure: HF switching Rectifier SMR with timer with reasonable structure design, isolated the inverter part and , rectification part , convenient to disassemble and maintenance |

Radiator: radiator capacity expanded 1.5 times,make sure better cooling effect | switch control way: adopt full bridge phase shifting soft switch,reduct IGBT loss,save engergy |

Main transformer: 60v 125A Switch Mode IGBT TR rectifier for electrochilorination system adopts amorphous core,increase transformer efficiency,reduct the transformer temperature rise,cut the rectifier weight,improve the power supply stability, reliability | Core & Schottky diode: core capacity expanded 1.5 times schottky diode expands 4 times

|

Board : all control boards did anticorrosion treatment with imported three defense lacquer | IGBT: IGBT capacity expanded 3 times,make the power supply more reliable |

Application ofHF switching Rectifier SMR :

Mainly used in non-ferrous metal electrolysis: aluminum, magnesium, zinc, lead, copper, manganese and manganese dioxide; gold, silver and other metals smelting; neodymium iron boron rare earth smelting; hard alloy, diamond smelting; salt water, potassium electrolysis to produce caustic soda, potash, sodium system; fire electrical heating materials, and other types of high-power DC power supply.

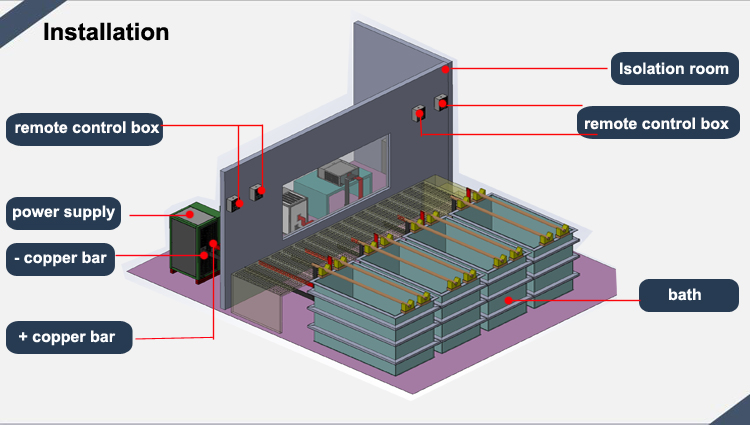

| 1, Placing rectifier and keep the body stability; ensure good ventilation. |

| 2, Checking anodizing rectifier out cover if loosing. |

| 3, Connecting shell to ground to prevent static electricity. |

| 4, Conecting the AC input wire |

| 5, Connecting the DC output copper bars |

| 6, Connecting the rectifier remote control box,if local control ,skip this step |

| 7, Turn on air switch, then the fan starts to rotate and the power indicator light. |

| 8, Clockwise rotation adjustment button, voltmeter degree increases, working indicate light lighting. |

| 9, Adjust knob to maximum, then the voltmeter should indicate the rated voltage, current meter indicates the load volume accordingly. |

| 10, Disconnect the air switch, turn off the rectifier |