Chengdu Xingtongli Power Supply Equipment Co., Ltd. |

|

Verified Suppliers

|

|

air cooling 8V 2000A adjustable IGBT plating power supply machine

air cooling 8V 2000A adjustable IGBT plating power supply machine was used to electroplate nickel and other mental. Saving energy, light weight

and small size. We re-desgined 2000A rectifier. It could be smaller and lighter. The weight is lighter than before 10kg.

The magnetic deviation automatic correction circuit is adopted and the total power of magnetic core gets enlarged 1.5 times.

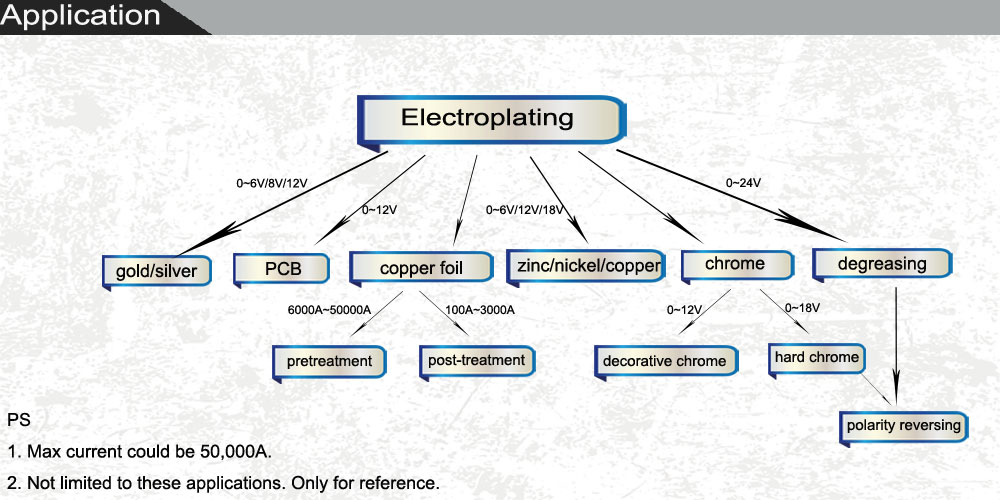

Application

Different volt and current has different applications

Specification

| SPECIFICATIONS FOR GKD(M)(H)10-2000CVC | |||

| Input AC | 380V±10% | 3phase | 50/60Hz |

| Output DC | Volt | 0~8V Adjustable | |

| Current | 0~2000A Adjustable | ||

| Power | 20KW | ||

| Efficiency | >85% | ||

| Switching Frequency | 20KHz | ||

| Protection | Short circuit protection Overheating protection Phase lack protection Input over/low voltage protection | ||

| Working Condition (Temperature) | -10℃~50℃ | Control mode | Panel control Remote control |

| Net weight | 80kg | Working mode | Constant Voltage(CV) Constant Current(CC) |

| Dimension(mm) | 480*600*740mm | Cooling way | Air cooling |

2. Control mode: Local control or Remote control(the length of

cable is determined by customers)

3. Japan IGBT(the default choice) or Germany IGBT are adopted

4. After being phosphated, galvanized and plastic sprayed, the

chassis has excellent corrosion resistence function

5. Easy to operate and repaire

Package:

1. Cabinet

a: Adopting completely digitalized machining

b: Adopting cold rolled production of iron steel sheet, after phosphorization, zinc plating, plastic spray, the rectifier gets better structural

strength and anti-corrosion.

c: Reasonable structure design, isolated inverter design,

rectification part is convenient to disassemble and mend because of

its neat assembling.

d: Radiator gets better cooling effect because of its 1.5 times capacity.

2 Electric control system

a: The rectifier adopts full bridge phase-shifted soft switch

control, ensuring the lowest power loss of IGBT. The capacity of

IGBT become 3 times bigger.

b: The main transformer. It adopts amorphous core to increase transformer efficiency and cool transformer, and not only can lighten rectifier weight,

but also can strengthen rectifier stability and reliability. At its

elementary stage, it adopts series blocking capacitor.

c: Magnetic deviation automatic correction circuit is adopted and

the total power of magnetic core gets enlarged 1.5 times.

3 Schottky Barrier Diode

a: It has been expanded 4 times.

4 All the controlling boards get antiseptic treatment with imported lacquer.

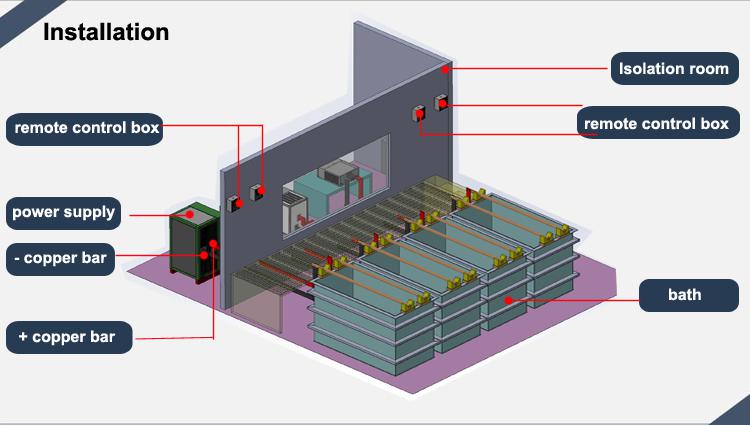

How to install rectifier

This is installation way for remote control rectifier. Not only

this way.

1. To connect copper bar with bath/tank

2. To ensure power supply/rectifier is grounded

3. To ensure there is enough water for water cooling type power

supply/rectifier

4. We advice that all rectifiers should be isolated to increase of

its life.

The user can adjust the 12V DC power supply according to the requirements:

During the use of 12 V DC power supply for electroplating, according to our company's experience, users can carry out regular inspection and maintenance according to the environment. The following are the simple steps of maintenance and overhaul:

Before opening the power box, disconnect the external power supply for more than 30 minutes.

After opening the power box, clean the dust of each part with a dry cloth or brush, or with compressed air, but pay attention not to over pressure to avoid damaging the components.

Check and confirm whether the power supply is normal and whether the air switch section is reliable.

Check whether the fan works abnormally and whether there is noise.

Check whether there is oxidation on the output copper bar or copper cable. If yes, please handle it in time.

Check the sealing condition of the 12 VDC power supply:

Check the screws and nuts for looseness.

For 12 V DC power supply with water-cooled plating, please check whether the rectifier machine is free of water, check whether there is water leakage, and tighten the retainer.