SHEAN (CANGZHOU) CORP LTD |

|

KGPS 500Kw 1000KW Medium Frequency Induction Billet Heating Furnace

Production Description of our Medium Frequency Power Source Use For Hot Pipe Bending Machine:

The product is suitable for casting industry, mainly used for smelting cast iron, carbon steel, high manganese steel, gray iron, ordinary scrap iron, alloy steel, non-ferrous metal (such as: copper, aluminum, silicon, etc.) and metals.The furnace body used is GW0.15t-0.20t.Best (note: aluminum housing, stainless steel housing, magnetic yoke steel housing).The selected customer factory must choose power transformer capacity range: 250KVA-315KVA. The failure rate is small, the maintenance is simple, the price is low and the durability is long.And get the plant going again.The power factor of this product reaches above 0.85 when running at full load.Please consult our sales staff before you choose this product.Only after knowing your usage and the actual situation of your factory can we select the best products for you.

Medium frequency kgps heating power supply for induction furnace

melting time: 0.5t/one hour

Configuration of KGPS-400KW induction furnace

1. power cabinet 400kw ,

2. aluminum shell furnace

3. capacitor

4. tilting reducer

5. tilting control box

6. water cable

Auxiliary device: (optional)

cooling tower

transformer

The Specification of our Medium Frequency Power Source Use For Hot Pipe Bending Machine:

| Model | Power Input | Power Output | Usage | ||

| Inlet line Voltage (V) | Inlet Currency | Frequency | Power Rate | ||

| 3 phases or 6 phases | (A) | (KW) | |||

| 50Hz | |||||

| KGPS-100 | 380 | 160 | 1--8 | 100 | Surface hardening, heating, melting. |

| KGPS-120 | 380 | 200 | 1--8 | 120 | Surface hardening, heating, melting. |

| KGPS-160 | 380 | 260 | 1--8 | 160 | Surface hardening, heating, melting |

| KGPS-200 | 380 | 320 | 1--8 | 200 | Surface hardening, heating, melting |

| KGPS-250 | 380 | 400 | 1--8 | 250 | Surface hardening, heating, melting |

| KGPS-300 | 380 | 480 | 1--8 | 300 | Surface hardening, heating, melting |

| KGPS-400 | 380 | 640 | 1--4 | 400 | Surface hardening, heating, melting |

| KGPS-500 | 380 | 800 | 0.5--2.5 | 500 | Surface hardening, heating, melting |

| KGPS-750 | 380 | 1200 | 0.5--2.5 | 750 | Surface hardening, heating, melting |

| KGPS-800 | 380/660 | 1300/730 | 0.5--1 | 800 | heating, melting |

| KGPS-1000 | 660 | 920 | 0.5--1 | 1000 | heating, melting |

| KGPS-1200 | 660 | 1100 | 0.5--1 | 1200 | heating, melting |

| KGPS-1500 | 660/750 | 1400/600 | 0.5--1 | 1500 | heating, melting |

| KGPS-2000 | 660/750 | 1800/800 | 0.2--0.5 | 2000 | heating, melting |

| KGPS-2500 | 660/750 | 2300/1000 | 0.2--0.3 | 2500 | heating, melting |

| KGPS-3000 | 660/750 | 2700/1200 | 0.2--0.3 | 3000 | heating, melting |

| KGPS-4000 | 750/950 | 1600/1280 | 0.2--0.3 | 4000 | melting |

| KGPS-5000 | 750/950 | 2000/1600 | 0.15--0.2 | 5000 | melting |

| KGPS-8000 | 950 | 2500 | 0.15--0.2 | 8000 | melting |

| KGPS-10000 | 950 | 3000 | 0.15--0.2 | 10000 | melting |

APPLICATIONS of our Medium Frequency Power Source Use For Hot Pipe Bending Machine:

A. Heating (hot forging, hot fitting and smelting):

B. Heat Treatment (surface quench):

It is mainly aims to change the rigidity of the metal materials through the heat treatment to work pieces. Detail applications are stated as follows:

C. Welding (braze welding, silver soldering and brazing)

It mainly aims to melt the solder by heating it to a certain temperature for the purpose of connecting two types of metals of the same material and different

D. Annealing (tempering and modulation)

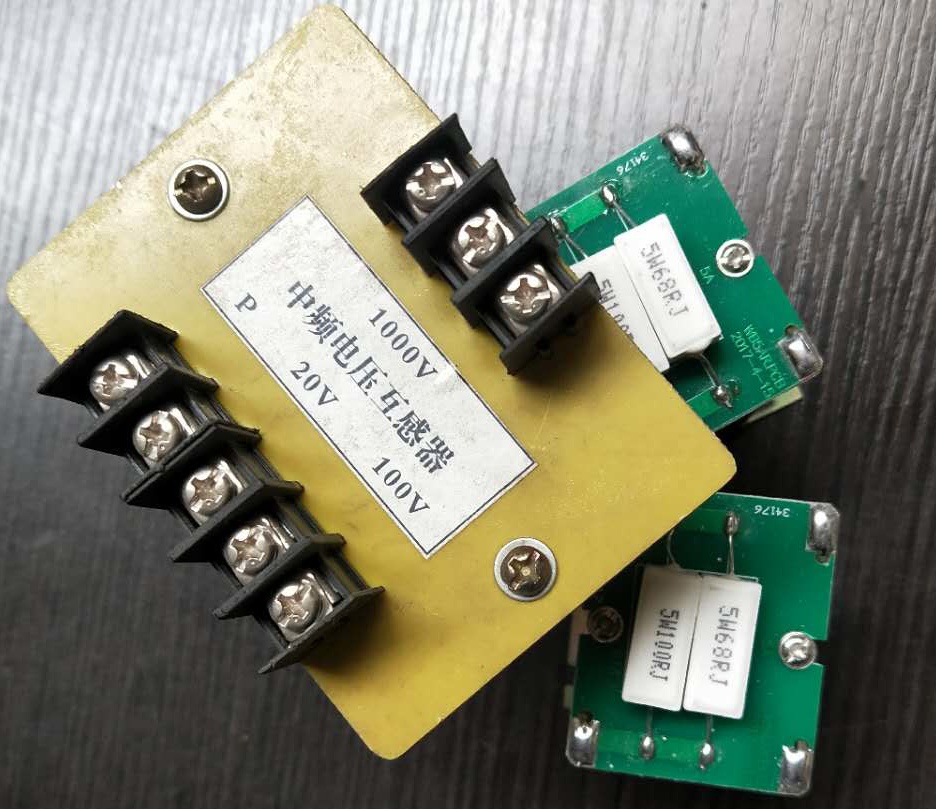

Electric Board

The main control circuit board is the core component of the machine.high quality. We have many stocks.

Main control circuit board as the main part of the machine, we made in their research and development, and adopted by the company and built since the automatic welding and testing equipment to ensure that each set of machine can achieve the best effect, and we have main control board in stock lone time, can satisfy the parts supply problems.

Induction coils

The induction coil inside the furnace body is treated with two insulations. The first spray of high temperature insulation paint. The second round of glass fiber tape. The service life of the treated furnace lining and induction coil will increase by more than two times.

Advantages of Our Heiyan Medium Frequency Power Source Use For Hot Pipe Bending Machine:

1. Energy saving:

The power factor reaches 0.99 under the condition of full power output. The integrated circuit board is adopted and the current and voltage are adjusted internally. The core components are high performance, high density and large-scale ASIC integrated circuit produced in the United States, which are digitized. The rectifier trigger part does not need any adjustment, and has the advantages of high fraud reliability, high pulse symmetry, strong anti-interference ability and fast response speed.

2. Big reactor design:

Strong filtering ability, greatly reduce harmonic pollution to the grid, suppress the current mutation, protect the transformer.

3. Large section area of current carrying discharge:

Select 8×60 copper row, large cross-sectional area, strong current carrying capacity, reduce heat.

4. Cabinet uses RITTAL brand:

Durable and beautiful

5. Appliances: SCHNEIDER brand

6. Button: IDEC brand

7. Insulating plate:Durable and high insulation grade, beautiful

8. Water segregator: Stainless steel

9. Cooling water pipe: Specially customized, high temperature and high pressure

10. Inverter increase resistance and capacity absorption: it can effectively suppress the instantaneous oscillation and high-frequency current of operating overvoltage, so that the waveform of overvoltage becomes slow, the steepness and amplitude are reduced, plus the damping effect of resistance, so that the high frequency oscillation rapidly attenuates.

NOTE:

Please do not touch any exposeed electric components and induction coils when it is starting work .Please close system if repair or moving . Refuse electrocute!

More Products except of our KGPS 500Kw 1000KW Medium Frequency Induction Billet Heating Furnace :

Elbow Forming Machine , Elbow Cold Forming Machine ,

Pipe Bending Machine , Hydraulic Press Machine ,Pipe Expanding Machine , Tee Forming Machine , Pipe Beveling Machine , Shot Blasting Machine , Band Saw Machine , Medium Frequency Power Source , Pipe Fitting Mould , Steel Pipe Fittings , Aluminum melting furnace IGPS , KGPS power supply , Ciosed cooling tower