HLS Coatings (Shanghai)Co.Ltd |

|

Verified Suppliers

|

|

Nano One Coating System paint

Nano One Coating System(NOCS in short) is a new generation double-component coating system, using a new type of Alicyclic Alkenamide Urea (AAU) as the film forming material, which is one kind of nanometer-material and a controlled polymerization material that could provide high cross-linked and hydrophobic coating for most metallic material.

1)Surface performance

Due to the characteristics of nanometer material, the formed film of NOCS is so dense and smooth that it is not easy to be contaminated, and its glossiness is high.

2) It performs well in early water resistance test which will be done when a box is off the production line, and there is no problem for production in winter and rainy days as well, because it is fast drying.

| Zinc rich shop primer | NOCS | NOCS (top coating with color) | Total | |

| Exterior system | 10um | 40um | 40um | 90um |

| Interior system | 10um | 60um | / | 70um |

NOCS performs 2 times better than waterborne paint in Alkali resistance and Acid resistance.

| System | Items | Nano OCS | WBP | Test standards |

| Exterior | Water resistance | 500hr; Adhesion 5B, pencil hardness 2H | 500hr; Adhesion 5B, pencil hardness HB | After 500 hours, no blistering, no shedding, no discoloration; GB-T 1733 |

| Alkali resistance | 96hr | 48hr | (25°C 0.1N NaOH), no blistering, no shedding, no discoloration; GB-T 9274 | |

| Acid resistance | 96hr | 48hr | (25°C 0.1N H2SO4), no blistering, no shedding, no discoloration GB-T 9274 | |

| Interior | Water resistance | 500hr; Adhesion 5B, pencil hardness 2H | 500hr; Adhesion 5B, pencil hardness HB | After 500 hours, no blistering, no shedding, no discoloration; GB-T 1733 |

| Alkali resistance | 96hr | 48hr | (25°C 0.1N NaOH), no blistering, no shedding, no discoloration; GB-T 9274 | |

| Acid resistance | 96hr | 48hr | (25°C 0.1N H2SO4), no blistering, no shedding, no discoloration GB-T 9274 |

NOCS performs 2 times better than waterborne paint in weathering resistance.

| System | Items | Nano OCS | WBP | Test standards |

| Exterior | Artificial accelerated aging resistance | ≥2000hr; △Ecmc 1.1, lost light 9% | ≥1000hr; △Ecmc 2.7, lost light 15% | Filtered Xenon arc radiation, no cracking, no chalking, no foaming GB-T 1865 Method 1 |

| Neutral salt spray resistance | ≥1200hr; 1.3mm | ≥600hr; 1.5mm | The unilateral rust width at the scratches is ≤2mm. There is no blistering, no rust, no shedding on the board surface. GB-T 1771 | |

| Hydrothermal resistance | ≥960hr; △Ecmc 1.5 | ≥480hr; △Ecmc 2.3 | No blistering rust and no cracking, allowing slight color change. GB-T1740 | |

| Interior | Neutral salt spray resistance | ≥1200hr; 1.3mm | ≥600hr; 1.6mm | The unilateral rust width at the scratches is ≤2mm. There is no blistering, no rust, no shedding on the board surface. GB-T 1771 |

| Hydrothermal resistance | ≥960hr; | ≥480hr; △Ecmc 2.6 | No blistering rust and no cracking, allowing slight color change. GB-T1740 |

NOCS performs better than waterborne paint in hardness, impact resistance and stain resistance.

| System | Items | Nano OCS | WBP | Test standards |

| Exterior | Hardness | 2H | HB | GB-T 6739 |

| Impact resistance | Positive 10 points; Recoil 8 points | Positive 10 points; Recoil 4points | ASTM D2794 | |

| Stone chip resistance | Level 0.5 (Damage area 0.2%) | Level 1.5 (Damage area 2.5%) | Method B DIN 55996-1 | |

| Stain resistance | Level 1 | Level 3 | 7 cycles, GB-T 9870-2013 | |

| Interior | Hardness | 2H | HB | GB-T 6739 |

| Impact resistance | Positive 10 points; Recoil 8 points | Positive 10 points; Recoil 4 points | ASTM D2794 | |

| Wear resistance | 29mg | 87mg | CS-17,500G,1000hr; ASTM D4060 | |

| Stain resistance | Level 1

| Level 3 | 7 cycles, GB-T 9870-2013 |

(Note: In stain resistance and stone chip resistance, the higher the level is, the smaller the number it uses.)

NOCS performs better than WBP in bending resistance and impact resistance.

Its better performance in bending resistance and impact resistance means that if friction or collision happened partly on the film surface during the usage, yet there will be no crack.

(Note: The sample panels were taken randomly from actual production line.

Left = NOCS (painted in blue color), Right = WBP (painted in white color))

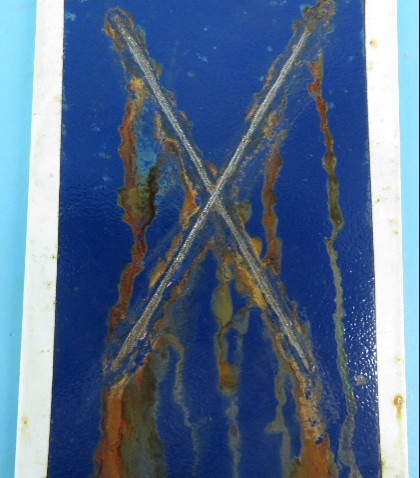

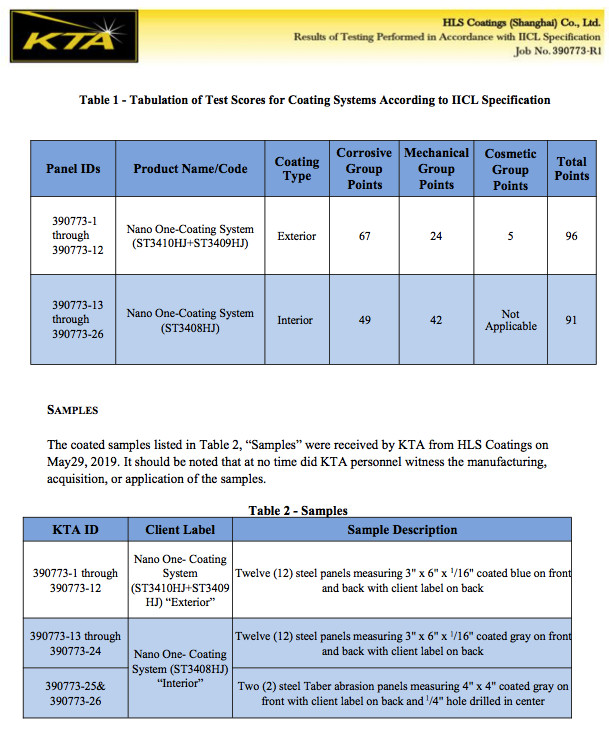

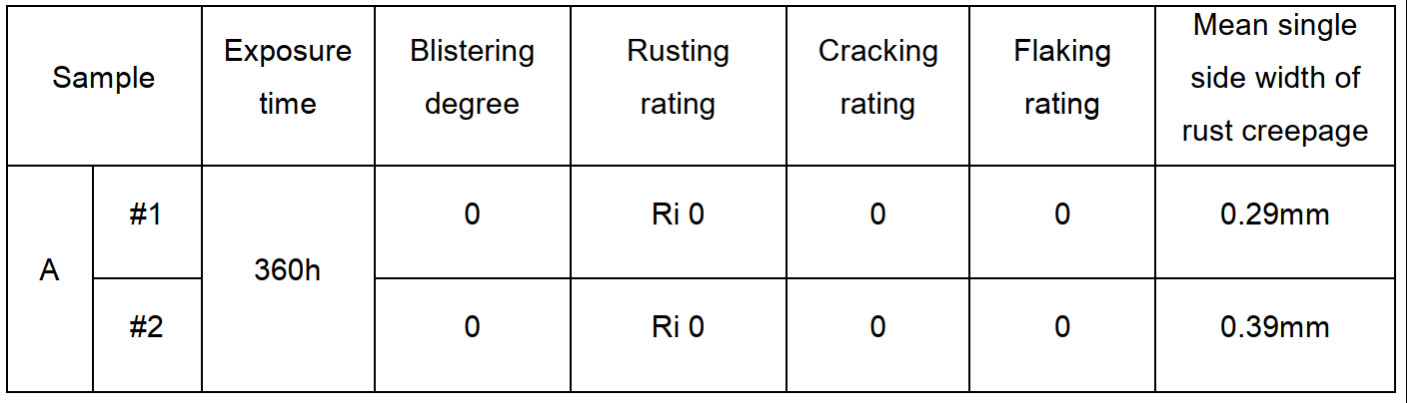

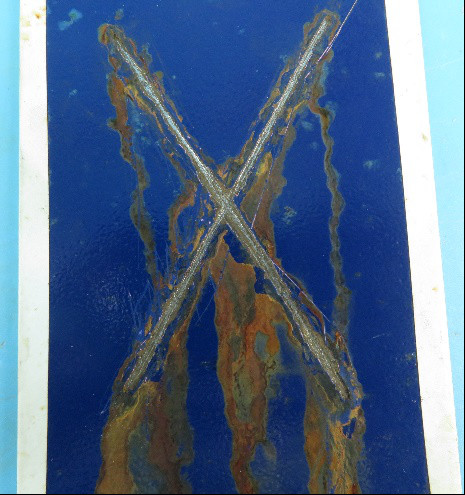

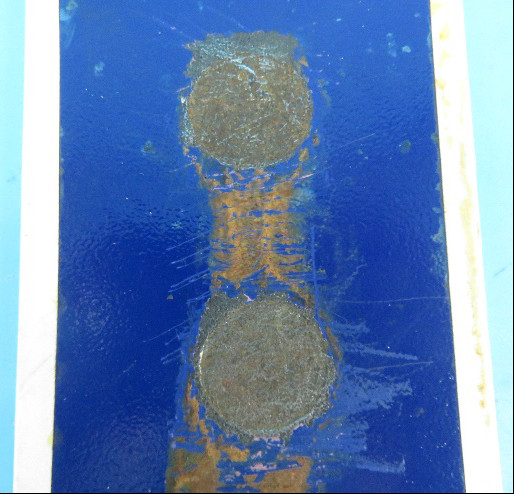

Theoretically speaking, 1 hour of CASS (Copper-accelerated Acetic Acid-Salt Spray) test equals 8 hours of NSS (Neutral Salt Spray) test, several sample panels were taken randomly from actual production lines and were sent to do CASS test to check its anti-corrosion performance.

| Coating system | Test results | |

| Exterior | 90um (Shop primer 10um + NOCS 80um) | CASS Test 360 hours (NSS Test 2880 hours ) |

| NOCS 90um, no shop primer | ||

| Interior | 70um (Shop primer 10um + NOCS 60um) | CASS Test 360 hours (NSS Test 2880 hours) |

| NOCS 70um, no shop primer |

The test results indicate that NOCS without zinc rich shop primer performs almost the same as NOCS with zinc rich shop primer, and NOCS performs better than waterborne paint, as it has passed 360 hours in CASS tests, which is equivalent to 2880 hours in NSS test, while conventional waterborne paint only meets 1000 hours in NSS test.

Detail:

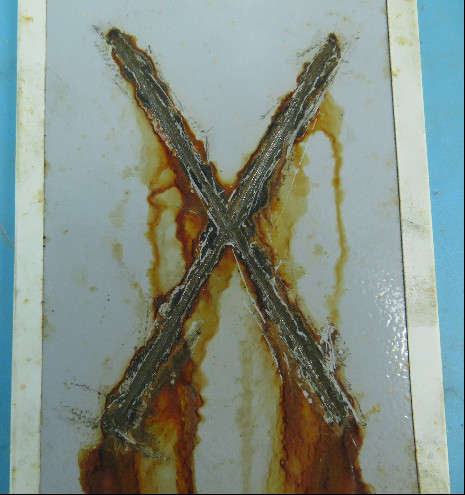

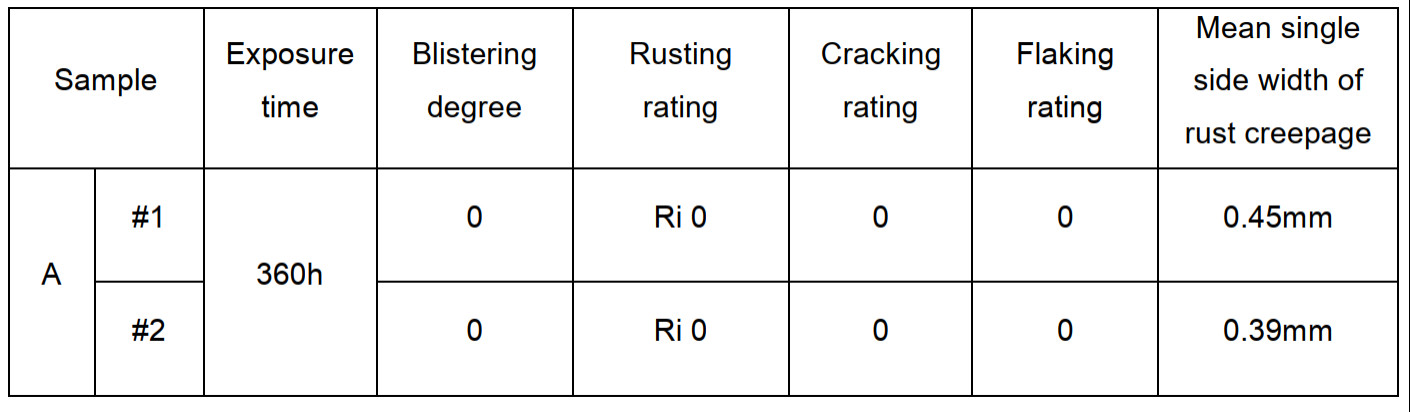

There is no rust, no blistering, no cracking and no flaking after 360 hours’ CASS test.

| |

| |

Tested sample-#1-Scribed area-360h (local part) | |

| |

Tested sample-#2-Scribed area-360h (local part) | |

| |

|

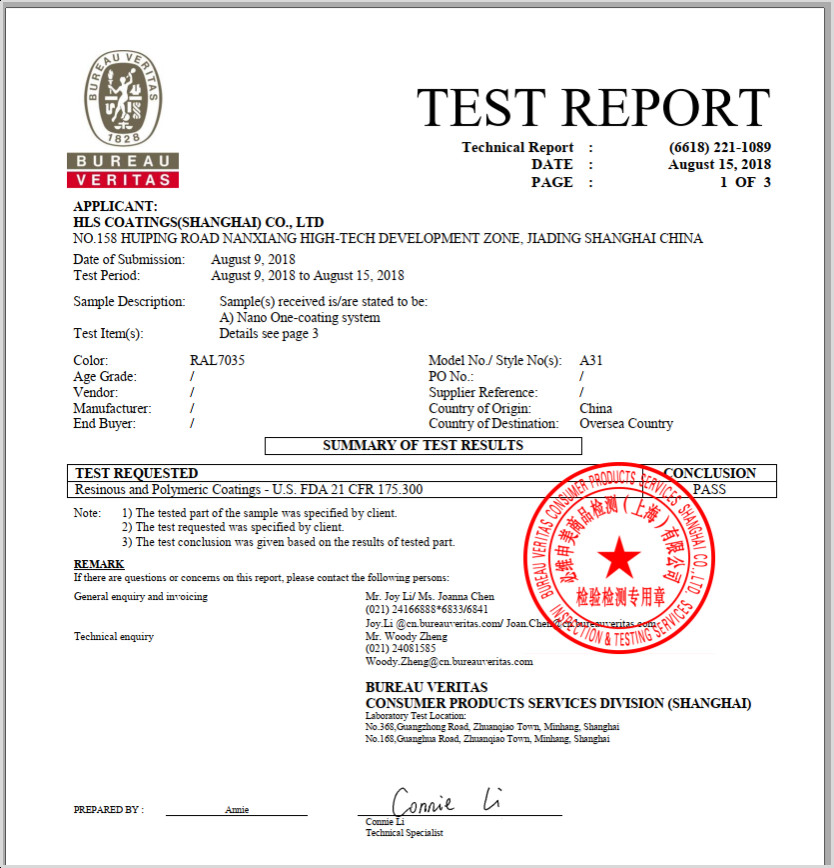

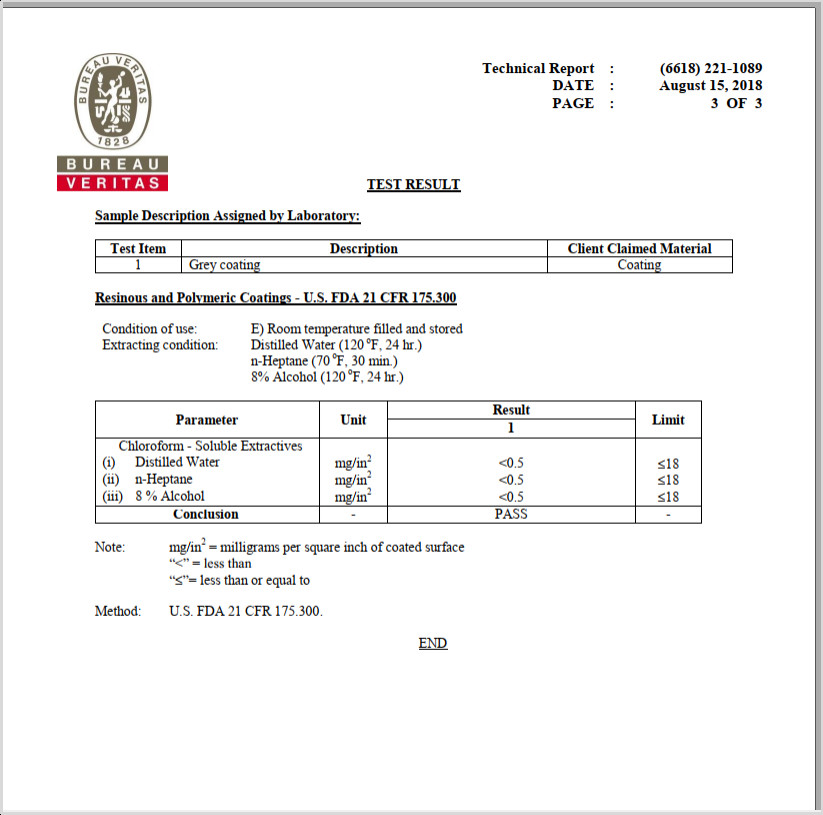

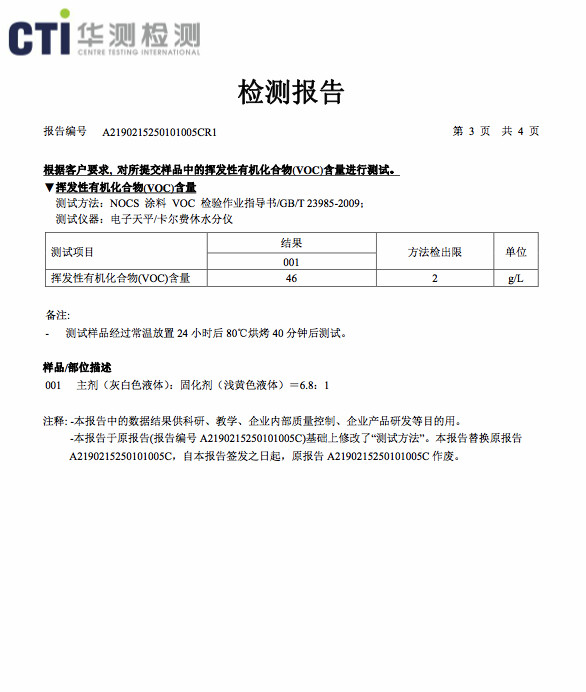

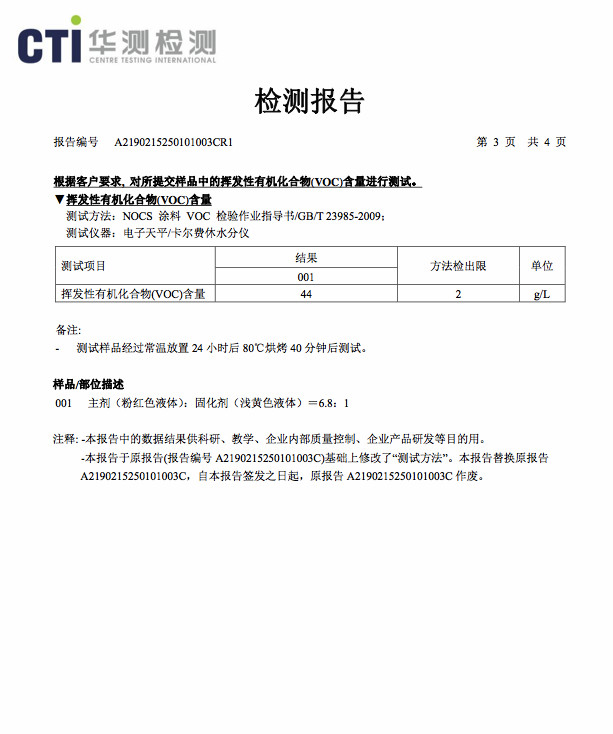

iii.VOC test result:

| |

|

|  |

|

There is no rust, no blistering, no cracking and no flaking after 360 hours’ CASS test.

| |

| |

Tested sample-#1-Scribed area-360h (local part) |

|

| |

Tested sample-#2-Scribed area-360h (local part) | |

B. Interior: 70um (Shop primer 10um + NOCS 60um)

There is no rust, no blistering, no cracking and no flaking after 360 hours’ CASS test.

| |

| |

Tested sample-#1-Scribed area-360h (local part) |

|

| |

Tested sample-#2-Scribed area-360h (local part) | |

C. Interior: NOCS 70um

There is no rust, no blistering, no cracking and no flaking after 360 hours’ CASS test.

| |

| |

Tested sample-#1-Scribed area-360h (local part) |

|

| |

Tested sample-#2-Scribed area-360h (local part) | |

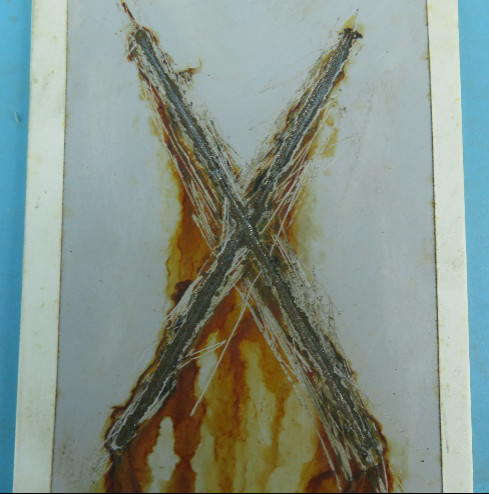

| Coating system | Test results | |

| Exterior | Inside circle: No paint Outside circle: 90um (Shop primer 10um+NOCS 80um) | CASS Test 360 hours (NSS Test 2880 hours) |

| Interior | Inside circle: No paint Outside circle:70um (Shop primer 10um+NOCS 60um) | CASS Test 360 hours (NSS Test 2880 hours) |

Detail:

After 360 hours’ CASS test, there is no rust, no blistering, no cracking and no flaking on the surface except the circle, and the corrosion area did not expand wider than original circle.

| |

| |

Tested sample-#1-Scribed area-360h (local part) |

|

| |

Tested sample-#2-Scribed area-360h (local part) | |

| |

Reference sample Tested sample-336h |

|

| |

| Reference sample Tested sample-360h | |

B. Interior: 70um (Shop primer 10um +NOCS 60um), No paint in circle

After 360 hours’ CASS test, there is no rust, no blistering, no cracking and no flaking on the surface except the circle, and the corrosion area did not expand wider than original circle.

| |

|  |

Tested sample-#1-Scribed area-360h (local part) | Tested sample-#2-Scribed area-360h (local part) |

| |

| |

Reference sample Tested sample-336h | |

| |

| Reference sample Tested sample-360h | |

HLS NOCS was a customized solution for heavy duty machinery, which had been applied for several years. It is environmental-friendly as it is solvent-free and can dry at room temperature. Nano-structure of NOCS is polyfunctional and contains high gel after crosslinking, which makes the film hydrophobic and wear resistant with some scratching self-healing performance and perform very well in chemical resistance (Alkali and Acid), temperature and hydrothermal resistance. Its better performance than waterborne paint in film hardness, impact resistance and corrosion resistance and its material characteristics of good sheltering performance, high glossiness, and good flexibility make us consider NOCS a comprehensive better choice as one kind of alternative coating solutions for container industry.