Dongguan Xianghe Paper Co., Ltd |

|

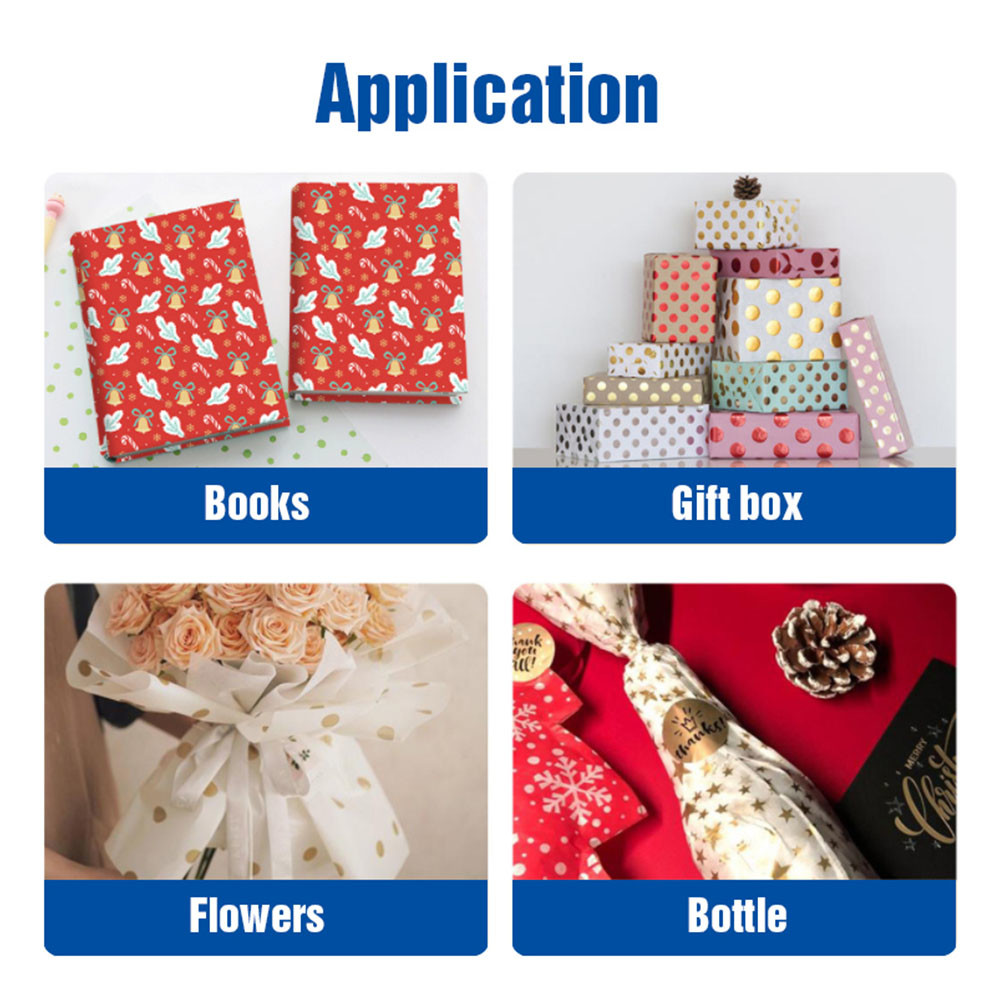

75CM*50CM DIY Wrapping Paper Handmade Craft Eco Gift Packaging Paper

Company and product Profile.pdf

Gift Packaging Paper Description

Wrapping Tissue Paper is a popular way to add an extra sophistication to a customer's purchase and at Precious Packaging, it can Pack for clothing, shoes, leather, hardware, cosmetics, hand bag, luggage, electronics, craft gifts, wine, hair,dailynecessities, porcelain, fruits and so on.

| product name | Printed Wrapping Paper,Gift Wrapping Paper |

| Color | Multi-Color,According to customers' specific requirements |

| MOQ | 500 sheets |

| Weight | 17-120g |

| Size | Custom Size,15g/ 17g / 22g / 28g Tissue Paper |

| Packing | Customered Requested |

| Usage | Packaging |

| Coating | Uncoated |

| Applicable printing | Screen Printing |

| feature | anti-collision ,Moisture Proof,Eco-friendly,Custom Logo |

| Pulp material | Wood Pulp |

| Pulp Style | Virgin |

| Pulping method | Chemical-Mechanical Pulp |

| country of origin | china |

| Brand | xianghe |

| Shipping | By Express or By Sea |

| Material of paper: | Tissue paper, Cotton paper, Glazed paper, Typing paper,100% virgin wood pulp (17gsm-80gsm thickness paper ) |

| Logo | Customer's Logo |

| Paper Type | Specialty Paper |

| Style | Roll or sheet |

| Custom Order | Accept |

| Paper style | Recyclable & Environment protection |

| Logo | All designs can custom by requirments |

More Information about the product:

1. PREMIUM QUALITY: Made from premium quality eco-friendly

material, which is truly a green choice.

2. USE ALL OCCASION: Perfect for birthday, holiday, Christmas,

wedding, Mother day, baby shower, graduation gifts wrap.It is also

great for craft project.

Exhibition

Tissue wrapping paper is a kind of advanced cultural industrial

paper that is quite difficult to produce. The technical

characteristics of this product are as follows: it has high

physical strength, excellent uniformity and transparency, and good

appearance properties.

It is delicate, smooth and smooth. , No bubble sand, good

printability. Generally, the production of printing paper is

divided

into two basic processes: pulp and papermaking. Pulp making is to

use mechanical methods, chemical methods, or a combination of the

two to dissociate plant fiber raw materials into natural pulp or

bleached pulp. Papermaking is to combine pulp fibers suspended in

water through various processes to form paper sheets that meet

various requirements. Paper mills generally need to store enough

raw materials for 46 months, so that the raw materials undergo

natural fermentation in storage to facilitate pulping,

while ensuring continuous production of the paper mill. Through the

preparation section, the reeds, wheat straw, wood and other raw

materials are cut into pieces or pieces of wood, and then the small

pieces of raw materials are placed in the digester to add chemical

liquid, and steam is used to cook, the raw materials are cooked

into pulp, or the pieces of wood are sent to grinding wood It is

grinded into pulp on the machine, and can also be grinded into pulp

after a certain degree of cooking. Then the pulp is washed with a

large amount of clean water, and the coarse pieces, knots, stones

and sand in the pulp are removed by screening and purification.

According to the requirements of the paper type, the pulp is

bleached to the required whiteness with a bleaching agent, and then

beaten by the beating equipment. Then add various auxiliary

materials such as filler, glue, sizing agent and so on to improve

the performance of the paper, and then purify and screen again, and

finally send it to the paper machine to filter the water through

the mesh, press dehydration, dryer drying, calender roll Take and

cut and rewind or cut to produce roll paper and flat paper. If the

production is to produce coated printing paper, it is necessary to

dry the middle part or produce roll paper and then apply the

coating process.