Xinxiang Echo Supplies Co.,Ltd. |

|

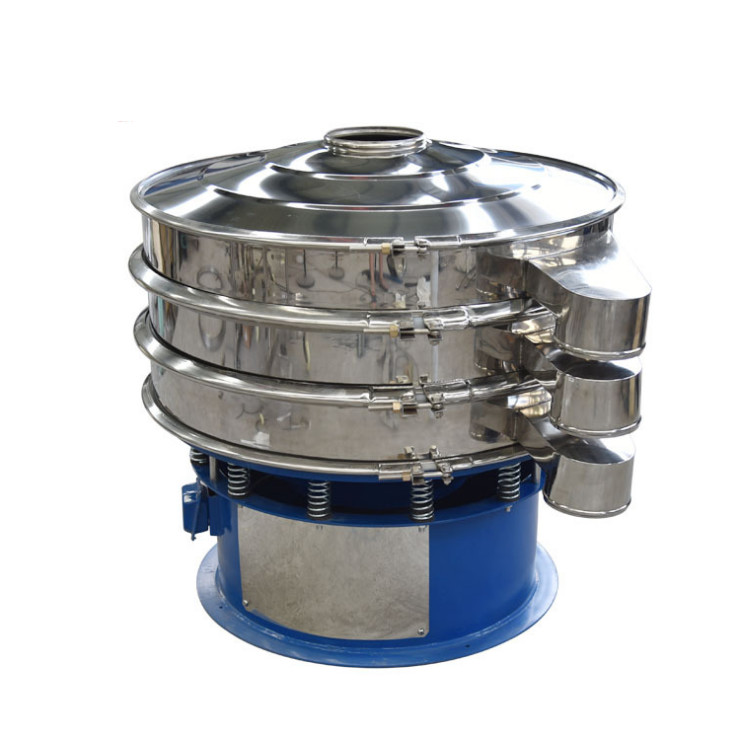

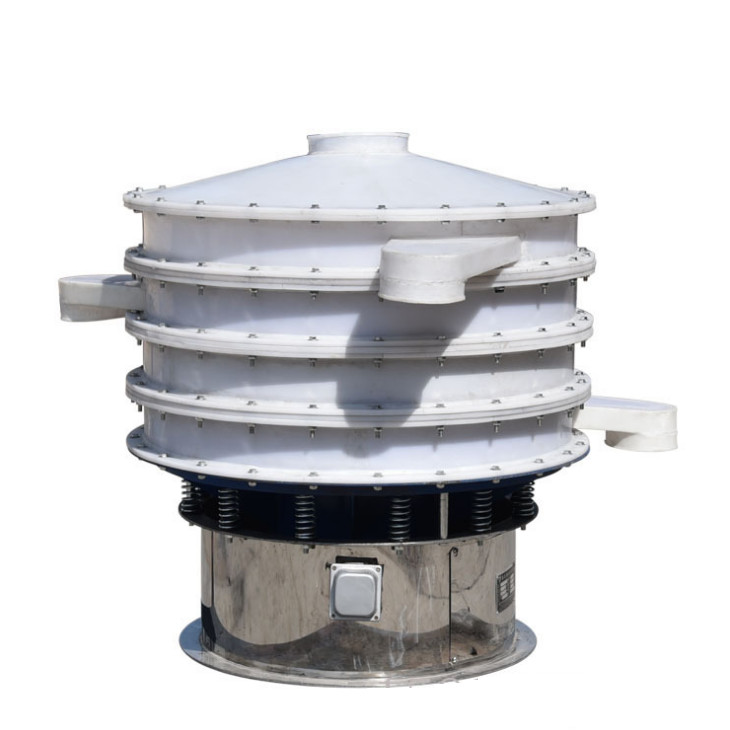

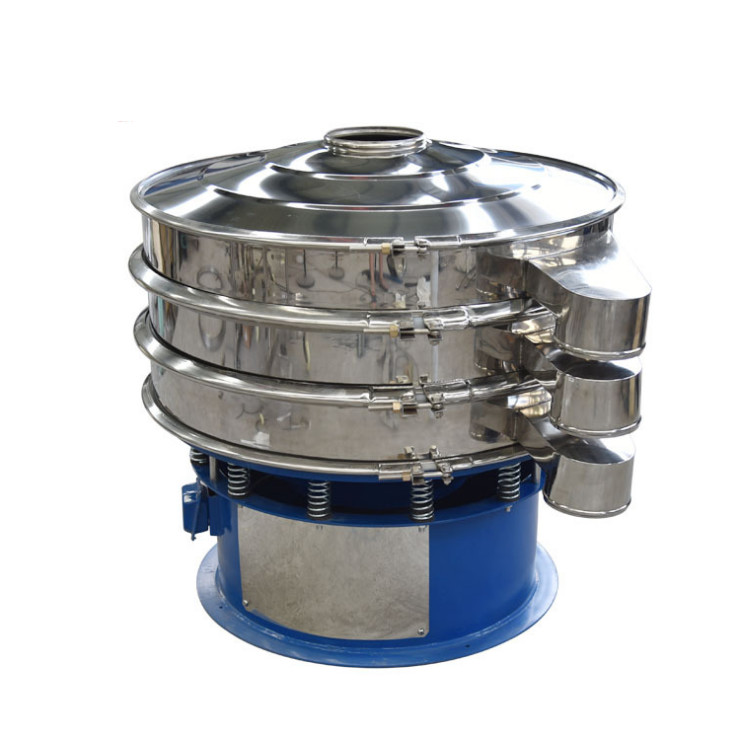

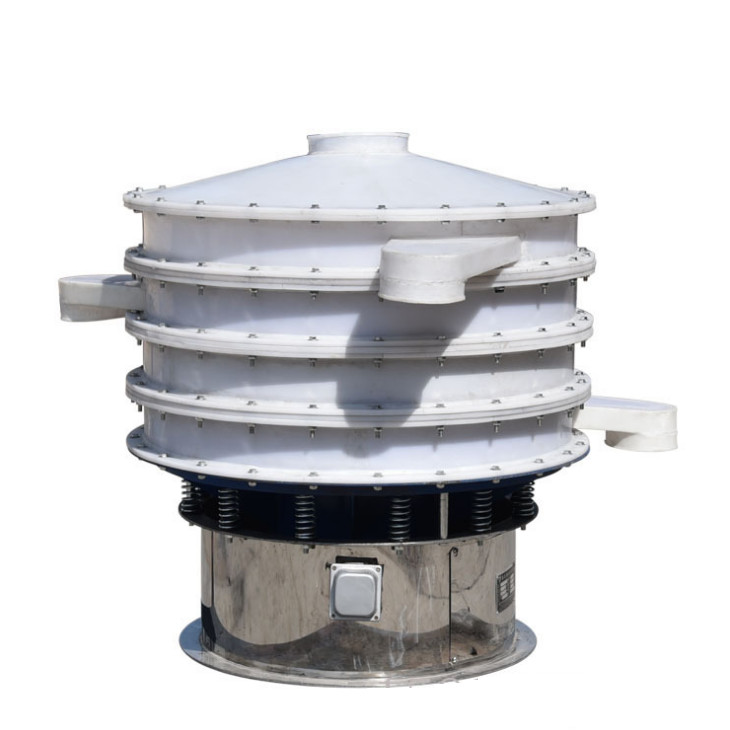

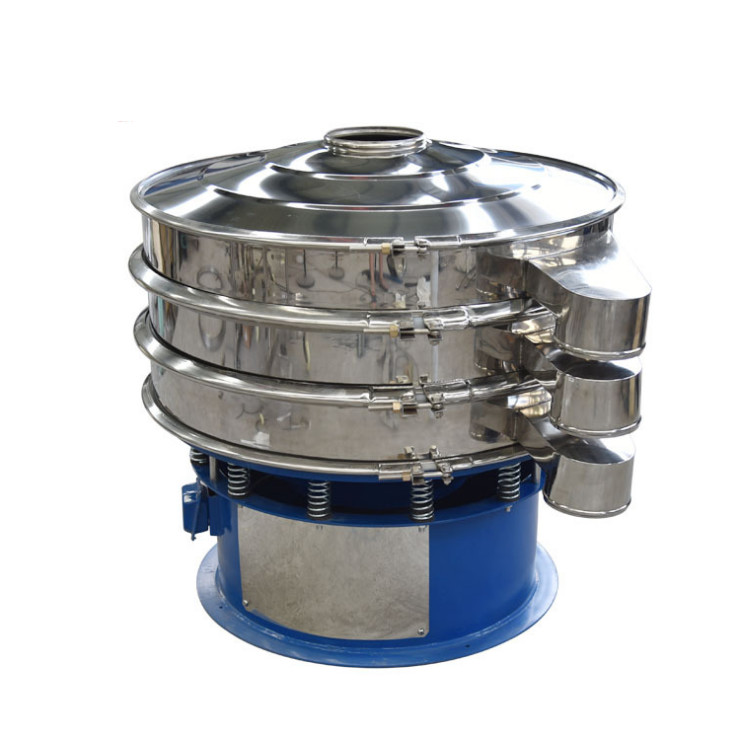

Rotary Vibrating Screen is a high-precision powder griddle, low noise, high efficiency, quick changer takes 3-5 minutes, totally enclosed structure, for grain, flour, mucus and other materials screening filter. Rotary Vibrating Screen is a motor for vertical excitation source, the motor and lower eccentric weight installed at both ends of the motor rotary motion into a horizontal, vertical, inclined three elementary motions, then the movement passed to the screen surface . Adjust the upper and lower ends of the phase angle, the material can change the trajectory of the screen surface

Structure

Feauture

1 high efficiency, compact design and durability, any powder and

mucus can be screening.

2 changer is easy, simple, easy to clean.

3 mesh is not blocked, the powder does not fly, can be screened to

600 mesh 0.018mm

4unique grid design, screen used for a long time for network speed,

screen up to 7 layers.

5 impurities, coarse material discharged automatically, you can

continuous work.

6 low energy consumption, maintenance is simple, without foundation

installation.

Principle

Rotary Vibrating Screen is a high-precision powder griddle, low noise, high efficiency, quick changer takes 3-5 minutes, totally enclosed structure, for grain, flour, mucus and other materials screening filter. Rotary Vibrating Screen is a motor for vertical excitation source, the motor and lower eccentric weight installed at both ends of the motor rotary motion into a horizontal, vertical, inclined three elementary motions, then the movement passed to the screen surface . Adjust the upper and lower ends of the phase angle, the material can change the trajectory of the screen surface.

Application

1) Chemical industry: resin pigment, medicine, grease, paint,

palette, etc.

2) Abrasive material and ceramic industry: building sand, mica,

alumina, abrasive, refractory material, slurry, etc.

3) Food industry: sugar, salt, alkali, gourmet powder, starch, milk

powder, yeast powder, pollen, food additive, bean milk, juice,

4) Paper-making industry: coated slurry, exhaust liquid, paper

making liquid and waste water reclamation, etc. Ultrasonic

Vibrating Screen

5) Metallurgy and mining industry: quartz sand, ore, titanium

oxide, zinc oxide, etc.

| Model | Diameter(mm) | Mesh area per deck (M2) | Mesh Size (mesh) | Layers | Vibration motor (KW) |

| EC-400 | Ø340 | 0.09 | 2-500 | 1-5 | 0.18 |

| EC-600 | Ø540 | 0.23 | 2-500 | 1-5 | 0.55 |

| EC-800 | Ø740 | 0.43 | 2-500 | 1-5 | 0.75 |

| EC-1000 | Ø900 | 0.66 | 2-500 | 1-5 | 1.1 |

| EC-1200 | Ø1100 | 1 | 2-500 | 1-5 | 1.5 |

| EC-1500 | Ø1400 | 1.58 | 2-500 | 1-5 | 1.5 |

| EC-1800 | Ø1700 | 2.32 | 2-500 | 1-5 | 2.2 |

| EC-2000 | Ø1920 | 2.8 | 2-500 | 1-5 | 2.2 |

Installation and commissioning:

( One) equipment shall have a stable foundation. When the device is

installed in the normal ground or cement base , you can not set the

anchor bolts. When the device is installed in the steel gantry

above , the application of bolt on steel body and steel gantry

should have some rigidity . The machine just a phase switch ( Note

: It is best to use electrical control panel ) , with snakeskin

pipe threading , the motor can be connected to the power supply ,

pay attention to the electrical control panel should be mounted to

a wall hanging .

( Two ) device is shipped with the screen properly installed , the

process of using screen replacement can replace themselves .

( Three ) before starting , you should first check the tightness of

the bolts , and the discharge port positions are aligned with the

catcher , and observe whether the normal rotational vibration motor

and the spring force without obstruction, check the layer mesh is

pressed .

( Four ) when vibration sieve access electrical control panel , you

should first check the electrical control panel . Observed after

the line is connected vibration motor rotation direction is

clockwise ( Note: The phase sequence should be changed otherwise )

is functioning properly, there is no different from noise.

( Five ) adjustable upper and lower eccentric vibration motor phase

angle to accommodate a variety of materials screening situation .

Detailed Images

1 SET/ POLYWOOD CASE

We mainly export Vibrating machine, Lifting machine,

mainly in

powder, starch, flour, rice flour, carbon powder, graphite powder,

manganese powder, lithium carbonate Field.

1. We have very more experience in

export business.

2. All of our products comply with international quality standards.

3.We can do customer’s design and requirement

4. We mainly export to Europe , Americal , South Americal, Africa, the Middle East. Australia, New Zealand etc.

| ¢340 |