Xinxiang Echo Supplies Co.,Ltd. |

|

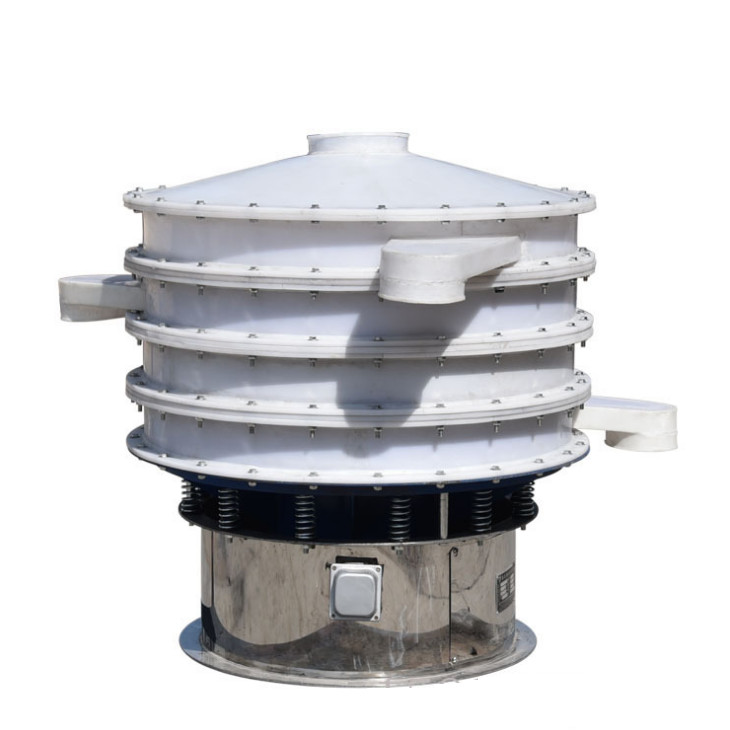

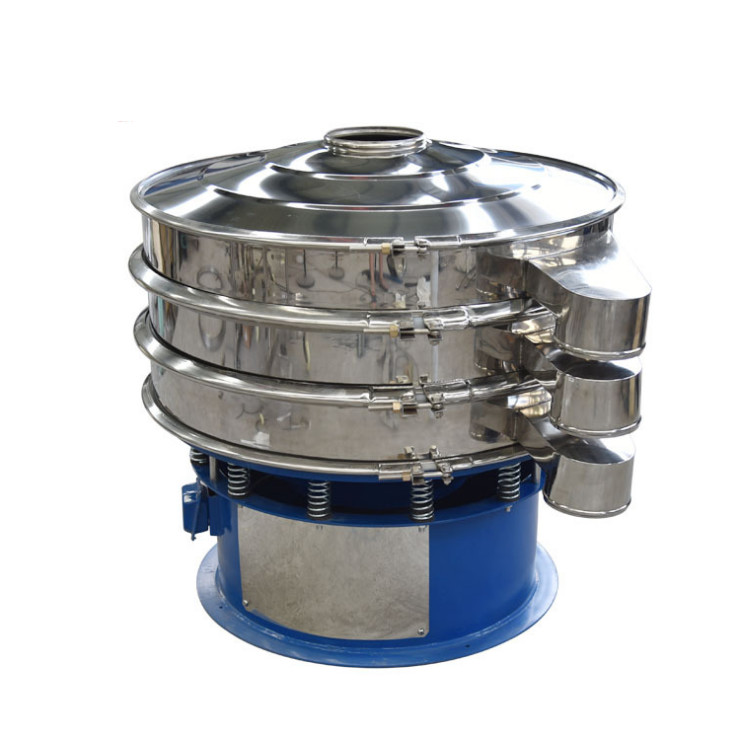

1-6 High Frequency Industrial Round Chemicals Tumbler Circular Seperation screen for processing bulk materials

Vibration Filter Introduction

HXSY series tumbler screen machine is a kind of inertial equipment

with mature technology and classical application.Its new design

Philosophy and unique structure making it the closest manual screen

machine.

| Model | Availability of screening area (m*m) | Screen slope (angel) | Grain size(mm) | Frequency(r/min) | Double amplitude(mm) | Power(kw) | Process capacity(t/h) |

| HXSY-600 | 0.292 | 0-10 | ≤100 | 5-8 | 0.25 | 6-10 | |

| HXSY 2.2-1000 | 0.785 | 0-10 | ≤100 | 5-8 | 1.5 | 8-5 | |

| HXSY -1200 | 1.13 | 0-10 | ≤100 | 750 | 5-8 | 2.2 | 15-30 |

| HXSY -1600 | 1.83 | 0-10 | ≤100 | 960 | 5-8 | 2.2 | 25-50 |

| HXSY -2000 | 2.63 | 0-10 | ≤100 | 1500 | 5-8 | 4.0 | 30-60 |

| HXSY -2600 | 5.31 | 0-10 | ≤100 | 5-8 | 5.5 | 45-60 |

Because of the motion trajectory of the griddle box, the Tumbler screen machine is also called compound circle screen. The vibration force produced by the drive system is a kind of inertia force which is circling the dead axle and changing regularly. Intrinsically, it is a kind of centrifugal force given by the eccentricity mass circling around the dead axle. The sieve is ususlly installed horizontally or with tiny angle(0°-5°). The principle is:when you start the machine, the vibrating part ---the screen box takes circling motion under the influence of the vibrating force.The screen box drive the sieve to take circling motion periodicity,so the material on screen surface take bounce motion, meanwhile, the material less than the aperture drop to the next deck,and the oversize are discharged by the outlet.Finally ,the screening work is completed. From the aspect of its structure and working principle, the exciter can circumgyrate in two ways according to the motion of the material, uniformily or contrarily. As a result ,we'd better make a choice between throughput and efficiency according to our practical demand.

Features

l1.Up to 5 times output per unit area.

2. Sieving efficiency is as high as 90% -95%.

l3.The acceleration is 4.5 times lower than vibrating sieve.

l4.Sieving parts’ increases the life expectancy and reduces maintenance.

l5.Up to 5 times output per unit area.

Applicable Industries

1. Chemical industry: resin, pigment, cosmetic, coatings, Chinese medicine powde.

2. Food industry: sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce.

3. Metallurgy, Mine industry: aluminum powered, copper powder, ore alloy powder, welding rod powder.

4. Medicinal industry: all kinds of medicine.

5. Waste treatment: disposed oil, disposed water, disposed dye waste water, active carbon.

soybean milk.

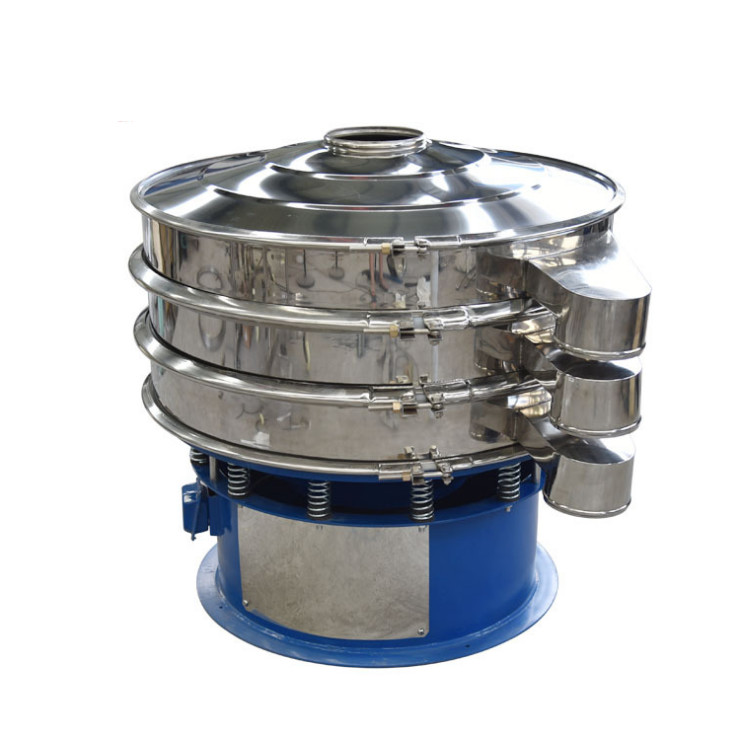

Detailed Images

1 SET/ POLYWOOD CASE

We mainly export Vibrating machine, Lifting machine,

mainly in

powder, starch, flour, rice flour, carbon powder, graphite powder,

manganese powder, lithium carbonate Field.

1. We have very more experience in

export business.

2. All of our products comply with international quality standards.

3.We can do customer’s design and requirement

4. We mainly export to Europe , Americal , South Americal, Africa, the Middle East. Australia, New Zealand etc.