Easy Fashion Metal Products Co., Ltd. |

|

Best China Supplier Atomizing Molten Metal Powder Equipment for Superfine Powder Production

1. Overview

Metal Powder Atomizing Equipment is characterized by small environmental pollution, high degree of ball-shape powder, low oxygen content and fast cooling rate and so on.

The range of particle distribution produced by our Metal Powder Gas

Atomizing Equipment is 10~200μm, and oxygen content in metal powder

is very low to 100~500ppm. Our atomization equipment have

experimental and production types.

Related Names: Gas Atomizing Equipment, Aluminum Powder Production

Line, Metal Powder Plant, Metal Powder Atomizing Equipment, Metal

Powder Making Machine

Combined with high vacuum technology, high temperature melting technology and high pressure gas atomization technology, vacuum melting gas atomization powder manufacturing equipment is especially suitable for the production of high quality powders and active metals/alloys.The atomized powder feature high purity, low oxygen content, high yield of fine powder, good appearance,etc.

2. Working Principle

3. Main Technical Parameters

| Model of gas atomization equipment | EF-30 | EF-50 | EF-100 | EF-300 | EF-500 | EF-1000 |

| Capacity (calculated in steel) | 30kg | 50kg | 100kg | 300kg | 500kg | 1000kg |

| Gas pressure (MPa) | 3-10 | |||||

| Gas flow rate | 10000-30000 | |||||

| Max. melting temperature (°C) | 1750 | |||||

| Temperature measuring | Infrared, WRe5-26 | |||||

| Power supply | 380V, three-phase, 50Hz | |||||

| Tundish heating power (kW) | 20-45 | |||||

| Vacuum rating | 6×10-3Pa or non vacuum | |||||

| Cooling water flow rate (L/min) | 150 | 150 | 150 | 300 | 400 | 700 |

| Heating power (kW) | 50 | 80 | 130 | 200 | 260 | 400 |

| Overall size (L×W×H) (mm) | 7500× 4000× 6500 | 7500× 4200× 6500 | 8200× 4200× 6500 | 8200× 4500× 6500 | 8500× 4500× 6500 | 9200× 5000× 6500 |

| Water cooling system | Air-cooling tower, water cooling unit, heat exchanger | |||||

| Soft water flow rate (m3/h) | 6-20 | |||||

| Controlling method | IPC or PLC | |||||

| Operation interface | Button or touch screen | |||||

| Data recording | Recorded by 12 data items and displayed in LCD monitor | |||||

Optional functions:

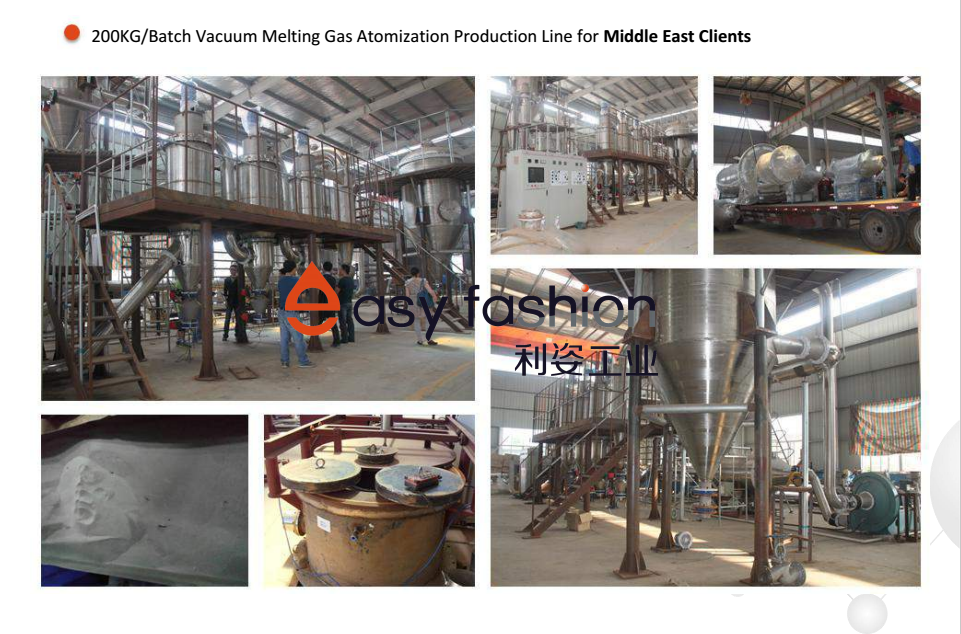

4. Some Customers Cases

5. Company Introduction

FAQ

1. How can I know your factory can produce equipment I need?

Re: Contact us and let us know your requirements of equipment. Then we will send these requirements to our technical department. So we will know whether our factory can offer you equipment or not.

2. Does your company customize equipment for customer?

Re: Yes, we can customize equipment according to customers' requirements.

4. How can I believe your quality?

Our equipment are eqquiped with mechanical parts of world renowned brands like Schneider, Omron and so on, and also approved ISO9001 certification.

SEND US AN INQUIRY NOW !