Easy Fashion Metal Products Co., Ltd. |

|

1. Introduction

Metal or alloy are made into consumable electrodes as feedstock. Its end face is heated by plasma torch and melt into molten liquid, then the molten is ejected by the centrifugal force of high-speed rotating electrode, crushed into small droplets and solidified into powders. Helium is the best choice as protective atmosphere because its thermal conductivity is highest and alsmost 10 times of Ar. By using helium, cooling speed can be increased and plasma torch performance can be improved.

This equipment is used for producing superalloy powders of 50-500 micron which are applied as materials for high temperature rotating components of turbine disc of aero engine, compressor disc, etc and for energy conversion devices of aerospace craft, nuclear reactor, petrochemical equipment, and coal conversion etc.

2. Features

(1) It used for producing high melting and alive metal powders, such as nickel-based or Ti-based alloy powder. It’s also suitable for producing various alloy powders, such as steel, cobalt, chromium, etc.

(2) The feedstock doesn’t contact with refractory materials during melting and atomizing processes, which eliminates non-metallic inclusions of pollution sources and produces clean powders.

p;producing various alloy powders, such as steel, cobalt, chromium, etc.

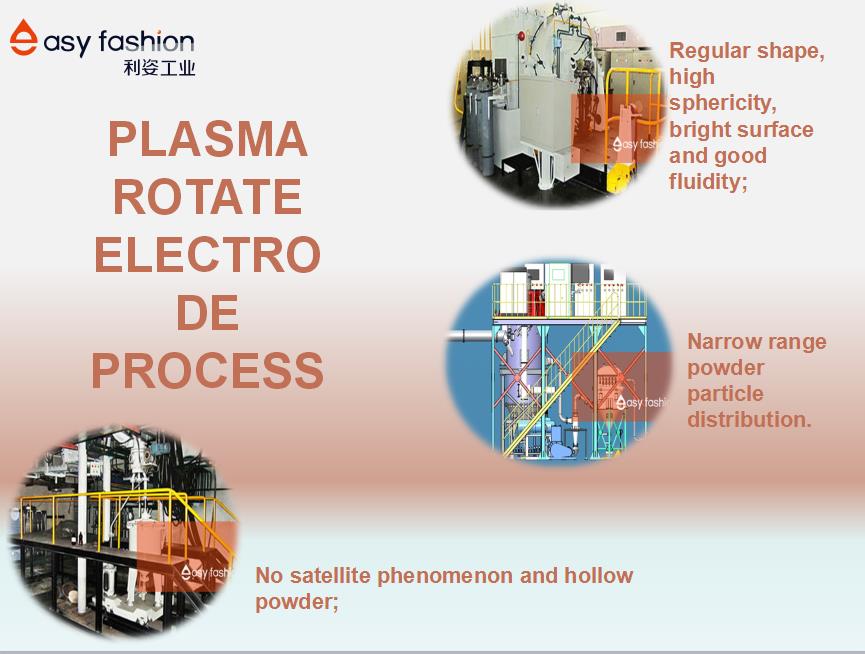

(3) The atomized powders is of regular shape, high sphericity, bright surface and good fluidity.

(4) There’s no satellite phenomenon and hollow powder.

(5) Powder particle distribution.

(6) Manufacturing numerous special alloy powders as fast solidification overcomes aliquation.

3. Main Technical Parameters

Total power: 150kw-200kw

Feeding method: rod raw continuous feeding; max. rotation speed 15000-16000r/min.

Powder size: D50=100-150μm

Powder quality: sphericity rate over 90%; oxygen content under 300ppm.

Gas consumption: pure Ar.

Capacity: 40~150/8hour.

Easyfashion Industry is a comprehensive product supplier with many joint ventures and cooperative enterprises, specializing in designing, manufacturing, and selling various kinds of industrial furnaces, such as heat treatment machines, material heat treatment machines and so on. Our company has many advanced powder and metallurgy products manufacturing and melting technology, specially with abundant technical foundations and production experiences of smelting and advanced material production equipments.

We can provide high pressure water atomization equipment, gas atomization equipment, vacuum gas atomization equipment, plasma atomization and centrifugal atomization of each batch of 3~1000KG Class. They can be used to produce iron-based powder, nickel-based powder, copper-based powder, silver-based powder, Ti, Mg, Al, Mo, W, SS and many other particle sized alloy powders. We can also customize equipment according to client’s special requirements.

1. How can I know your factory can produce equipment I need?

Re: Contact us and let us know your requirements of equipment. Then we will send these requirements to our technical department. So we will know whether our factory can offer you equipment or not.

2. Does your company customize equipment for customer?

Re: yes, we can customize equipment according to customers' requirements.

3. How to contact us?

Re: contact information as follows: