Shaanxi Aipu Solids Control Co., Ltd |

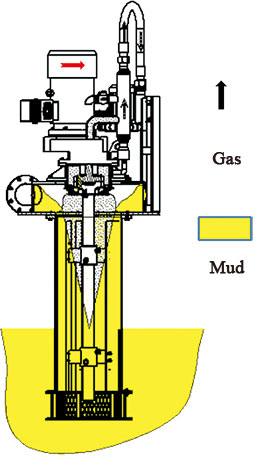

Centrifugal degasser, also called atmospheric Degasser is highly efficient equipment that removes gas from the gas cut mud by accelerating the fluid through a submerged centrifugal pump's impeller. APLCQ300 centrifugal degassers|atmospheric degassers have many advantages although the treating efficiency is practically the same which is above 85%. Normally degasser is installed after shale shaker and widely used in the various solids control system, and it is very important for recovering mud weight, stabilizing mud viscosity performance, reduce drilling cost.

APLCQ300 centrifugal degasser|atmospheric degasser accepts any

fluid weight or mud viscosity while the simple switch operation is

granted rapid startup and shutdown. The rugged bowl and custom

impeller extend part life. At start-up, drilling fluid enters the

submerged impeller and travels up to the elevated spray tank. A

circular disc (splash plate) turns the fluid into a high-velocity

sheet that strikes the wall of the bowl with enough force to

separate the gas from the fluid. The degassed fluid then flows

downstream through a discharge pipe.

| Model | APLCQ300 |

| Flow rate | 300m³/h |

| Fluids input ID | 20'' |

| Fluids discharge ID | 6'' |

| Gas venting ID | 2'' |

| Degassing capacity | 30m³/h |

| Main motor | 22kw |

| Pump motor | 1.1kw |

| Weight | 1400kg |

| Dimension | 1150x1054x3110mm |

| Electrical system | 380V/400V/415V/440V/460V/480V/600V/660V |

It's a typical vertical degasser that occupies less space. Such

degasser is a rather powerful and energy-saving design. From the

drive to the filtration

The material of the impeller is stainless steel with highly

anti-corrosion. it's a typical vertical

Configuration at the input bottom leads to good performance and the ability to suit the different working conditions

The maximum water flow of 300 cubic meters per hour.

We, AIPU focus on the solid control industry for over 20 years and we have a professional technical team. Our products are appreciated by clients because of their high quality at a reasonable cost. AIPU products have served KDC, Burgan, SINOPEC, CNPC, Honghua, Petronas, Pertamina, and so on drilling companies and rig manufacturers. I firmly believe that by cooperating with us, you'll find that we are different from other suppliers and you don't need to spend energy time seeking other suppliers.

Vertical centrifugal degasser is an ideal equipment to separate gas after shale shaker and minimum mud tank space requirement to maximum mud tank clean mud storage capacity in whole solids control mud system. The centrifugal force is supplied by a suitable design of degasser and a mud feeding pump at the proper pressure.

A vertical centrifugal degasser provides an innovative and small footprint solution compared to the traditional vacuum degasser which is a larger footprint. It is using centrifugal force to separate gas instead of a conventional vacuum. We are one of the leading manufacturers of poor boy degasser, vacuum degasser, and centrifugal mud degasser.

Vertical centrifugal degasser is popular with more and more users. Given the compact design and its flow rate. Compared to other suppliers' degasser, AIPU provides high-quality products and services in detail. Such as drilling mud input and the vacuum pump design. Please feel free to contact us for more details

Other than the centrifugal degasser, AIPU builds vacuum degasser as

well and also other solids control equipment like linear motion

shale shaker, mud cleaner with cyclone and bottom shaker, decanter

centrifuge, mud agitator, and mud tank. Please contact us freely

for inquiry.