Lantian Precision Machinery Manufacturing (Dalian) Co.,Ltd |

| Product | Large Foundry 30 Years Experience Log Wax Investment Casting Steel |

| Process | Sodium Silicate Process, Solica Sol Process, Compound Process, CNC Machining |

| Material | Carbon steel, Alloy steel, Stainless steel |

| Service | OEM Designed |

| Casting tolerances | ISO 2768-mK, VDG P690 D1-D2, ISO8062-3-2007 DCTG4-6, GCTG4-6 |

| Casting roughness | Ra1.6-3.2 |

| Machining roughness | Ra0.8-3.2 |

| Casting weight range | 0.05-80kgs |

| Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR |

| Surface treatment | Zinc plating, Polishing, Anodizing, Painting, Nickel plating |

| Heat treatment | Annealing, Normalizing, Hardening, Tempering, hardening |

| Quality Control | IATF16949:2016, ISO14001:2015, ISO9001 |

| Application | Auto Parts/Machinery Parts/Ship Parts/Valve Parts/Construction parts/Industrial Components |

4. Wax Removal

About Us:

Dalian Yemi Technology is a sales part of Lantian Precision Casting Group, who is specialized in Investment Casting and Machining for more than 20 years, It can produce Stainless Steel Casting, Carbon Steel Casting, Low Alloy Steel Casting, and processing can be done including Sodium Silicate Processing, Silica Sol Processing and also a kind of compound type processing, which realized good quality and lower cost compared to Silica Sol Processing Casting and Sodium Silicate Processing Casting.

Currently the company has 4 branch factories and covers an area of 19000.00 square meters, total assets is over 40 millian RMB, we have one sodium silicate processing foundry, 1 silicon sol processing foundry,1 machineryh processing and 1 mold processing plant, also one sales company Dalian Yemi Tech, total employees is over 400, and including 40 engineers and managers.

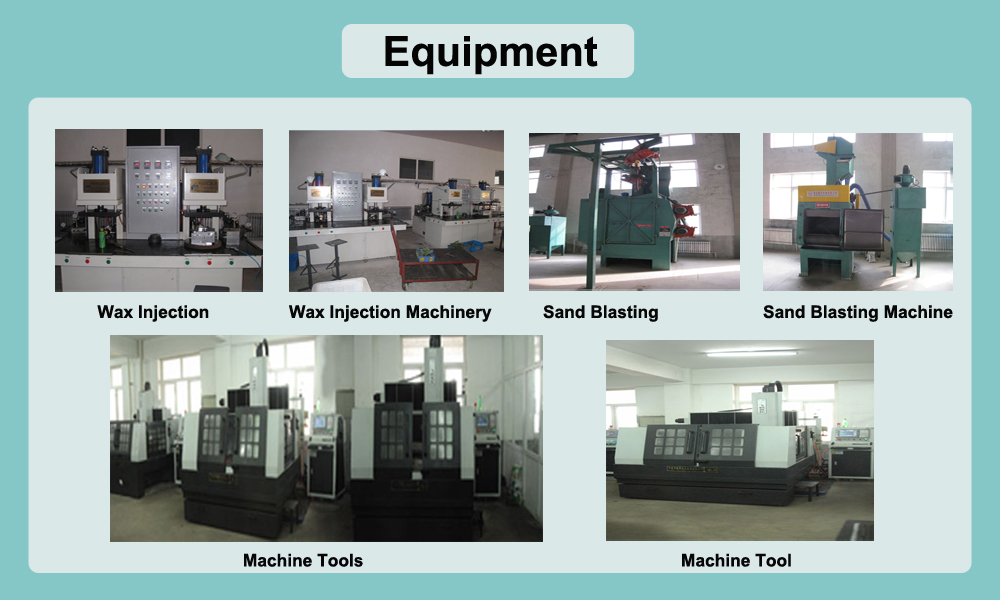

The company has advanced casting machinery,including:

Sodium Silicate Processing Machinery:

Wax injection machines,

Shot blasting machines,

Grinding machines,

Blender,

DC Arc Welding Machines,

Intermediate Frequency Induction Electric Furnace,

Box type resistance Furnace,

Burning Kiln,

Silica Sol Processing Machinery:

Wax liquid treatment three-piece,

Wax injection machines,

Industrial cold water machines,

Moistening slurry machines,

Sand machines,

Spray sand machines,

Full automatic demineralized water controller,

Filter,

Die Machines,

Resistance Furnace,

Crawler shot blasting machine,

Double hook shot blasting machines

Fabrication Machinery:

Vertical Machining Center,

Cnc miling machine,

Vertical milling machine,

Cnc machine tools,

Universal radial milling machine,

Radial drilling machine,

Engine lathe,

Bandsaw machine,

Bow sawing machine,

Wire cutting machine tools

We have complete testing equipment to fullfill the quality requirement from our customers, such as chemical composition test, we have imported Italy F-20 direct reading spectrometer and Germany Q6 and also other spectrometers to analyze the elements C,Si, Mn, P,S, Ni, Cr, Mo, V, Ti, Al, Cu, Mg, Ce, Nb, B, W. To the physical performance testing, we can carry out Tensile test, impact test, hardness detechtion and metallographic analysis. The fluorescent magnetic partical detector can also be used for magnetic partical inspection, Ultrasonic inspection and coloring inspection.

Email: ltcasting@hotmail.com

Mobile: 0086-13478609753