Zhengzhou Baiyun Industrial Co., Ltd. |

|

BAIYUN Semi-metallic Material Car Brake Pad D1342 With Noise Reduction Shim

National Leadership in the Braking System Industry

Baiyun is the undisputed National leader in the production of brake

friction material. With its unrivalled expertise, Baiyun produces

high performance brake pads for the most popular cars in the

European, American and Japanese markets.

The superlative levels of technology and reliability of Baiyun products is founded on an integrated production process which encompasses every stage in the production process, from research and development and testing to casting and machining.

On top of this is an ongoing commitment to research and development that sets Baiyun apart as a leading name in its industry and allows the group to excel as both a manufacturer of reliable, durable brake pads for the world's most popular and widely sold cars, and as a supplier of state-of-the-art brake pads designed and produced specifically for the most exclusive and desirable models in every class.

| Material | NAO, Ceramic, Low metal | size | customized, OEM Standard Size |

| Car Fitment | Toyota, Honda, Nissan | Net Weight | 1.2kg |

| Quality | High | Gross Weight | 1.5kg |

| Packing | Color box | PAckage Number | 4pcs/set |

| Type | Brake Pad | Application | Front Wheel |

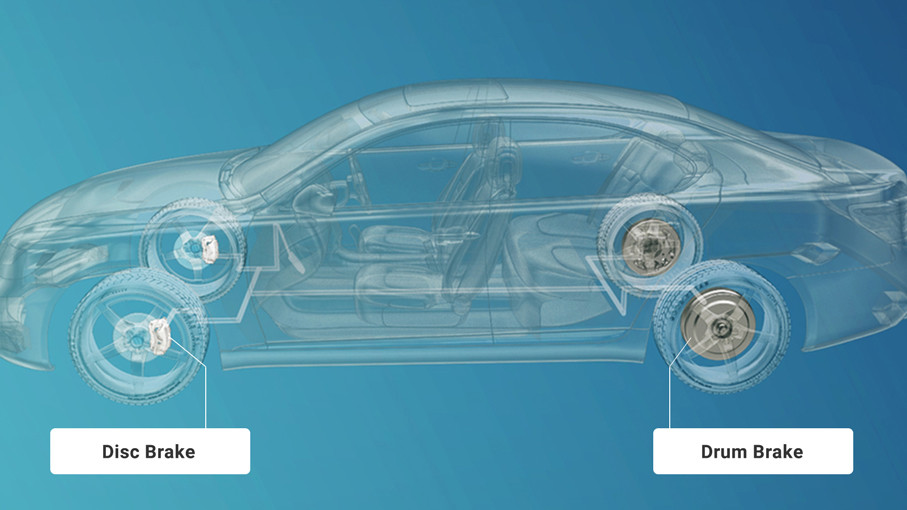

Types of Vehicle Brakes

1), Commercial Vehicle Brakes:

Commercial Vehicle---Drum Brake Linings

Commercial Vehicle---Disc Brake Pads

2), Passenger Car Brakes:

Passenger Car---Drum Brake Linings

Passenger Car---Disc Brake Pads

3), Motorcycle Brakes:

Motorcycle---Drum Brake Linings

Motorcycle---Disc Brake pads

Advantage of BAIYUN

PROFESSIONAL TEAM: Since 1977, focus on brake over 40 years;

Drafting unit of China friction&sealing material industry

standard

OEM & ODM: Top 10 of enterprises in friction material industry of China; OEM & ODM quality and service

EXCLUSIVE FORMULA: Safety, Comfortable,Asbestos-free,Wear-resisting,Heat-resisting,Less noise, Less disc injury

CERTIFICATE: ISO9001, ISO/TS16949, E-Mark, Link-Test Report, Greening-Test Report, SGS,MA,CNAS

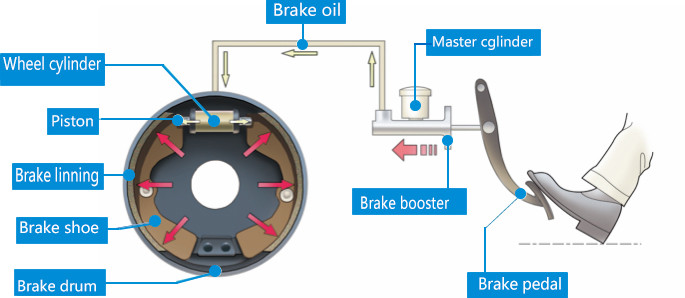

Brake Performance

1). Braking performance: friction coefficient (FF level: 0.35-0.45)

braking force: braking force, braking sensitivity

2), wear resistance: wear rate (6-100,000km) wear resistance.(with

driving habits, road conditions, climate, brake disc material

(different models, brake disc material is different, the weight of

the car is different)).

3). Comfort: whether there is noise, whether there is a sense of

braking, whether it is smooth.

4). Thermal recession: whether it is heat resistant -- the degree

of thermal recession.

5). Shear strength: whether it falls off, whether it is easy to

break, the density, whether the density is balanced, whether there

are bubbles and gaps.

Other items: whether damage brake disc, whether waterproof - water

recession degree, whether environmental protection, and brake disc

fitting degree.

Factors affecting product quality/performance:

1). Formula and materials:

a. What kind of materials are included in the recipe?Is the ratio

of various materials in the formula scientific and reasonable?There

are dozens of commonly used materials such as: Arron, copper fiber,

ceramic fiber, carbon fiber, synthetic graphite, six titanium

potassium acid whisker, powder nitrile, antimony sulfide, etc

b. Purity and quality of materials purchased by the company

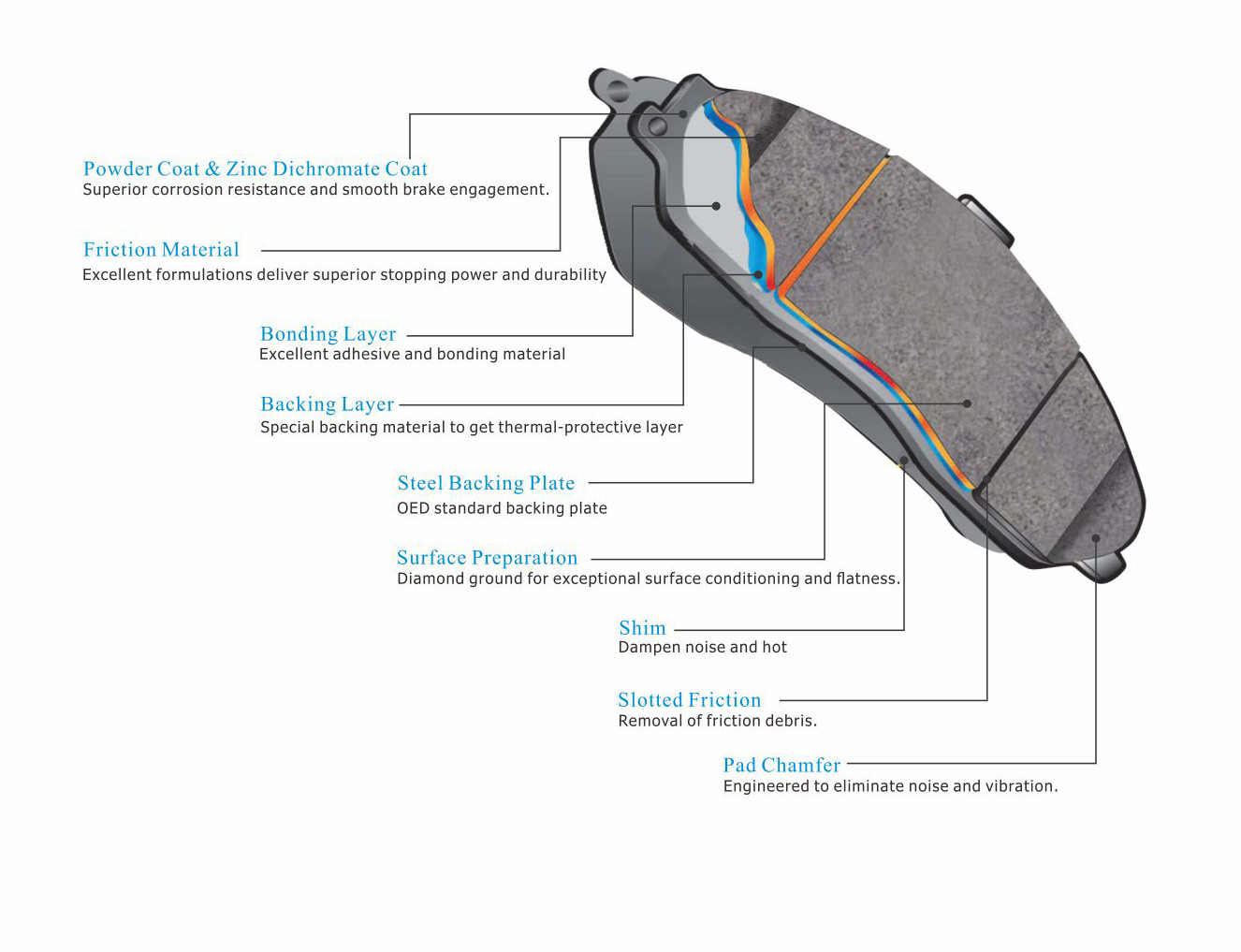

2). Components:

The quality of the components used, such as the disc brake sheet's

steel back and muffler, also affects the performance and quality of

the entire brake pad.

3). Processing technology:

a. Control management and protection of materials and components.

b. Pressing effect of pressing process, pressing pressure, whether

it is equal ratio pressing, pressing temperature and duration, etc.

c. Whether the heat treatment temperature and time are appropriate,

and whether the grinding process is fine and standardized.

d. Procedures such as sandblasting and polishing, adhesive coating,

marking and packaging, and control of semi-finished products and

finished products