Zhengzhou Baiyun Industrial Co., Ltd. |

|

Bus Disc Brake Pads WVA29087 Molde Ceramics Formula Green Testing

BAIYUN Bus Disc Brake Pads Supply for many Vehicles Brands as Followings:

DAF | Daimler AG (Daimler, EvoBus Freightliner, Fuso, Mercedes-Benz) | Dana Holding Corporation | Ege Fren | Haldex | Hendrickson | Inver Press | Kamaz | Knorr-Bremse | Knott Group | Krone Group (gigant) | | Meritor | Paccar (DAF, Leyland, Foden) | Schmitz Cargobull | Tuna Stålrör | Valx | Volvo Trucks (RVI, UD Trucks, Volvo) | WABCO | Beinben-Truck | BPW | Brakes India Limited | Wuhan Youfin Auto Parts Co (Youfin) | Yutong | ZF Friedrichshafen

Data of BAIYUN Bus Brake Pads

| Product | Bus Brake Pads |

| Part No. | WVA29087/WVA29179/WVA29042/WVA29085 |

| Size | 247.7*109.7*30mm |

| Friction coefficient | 0.35~0.45 |

| Warranty | 80,000-100,000km |

Bus Brake Pads Repare Kits

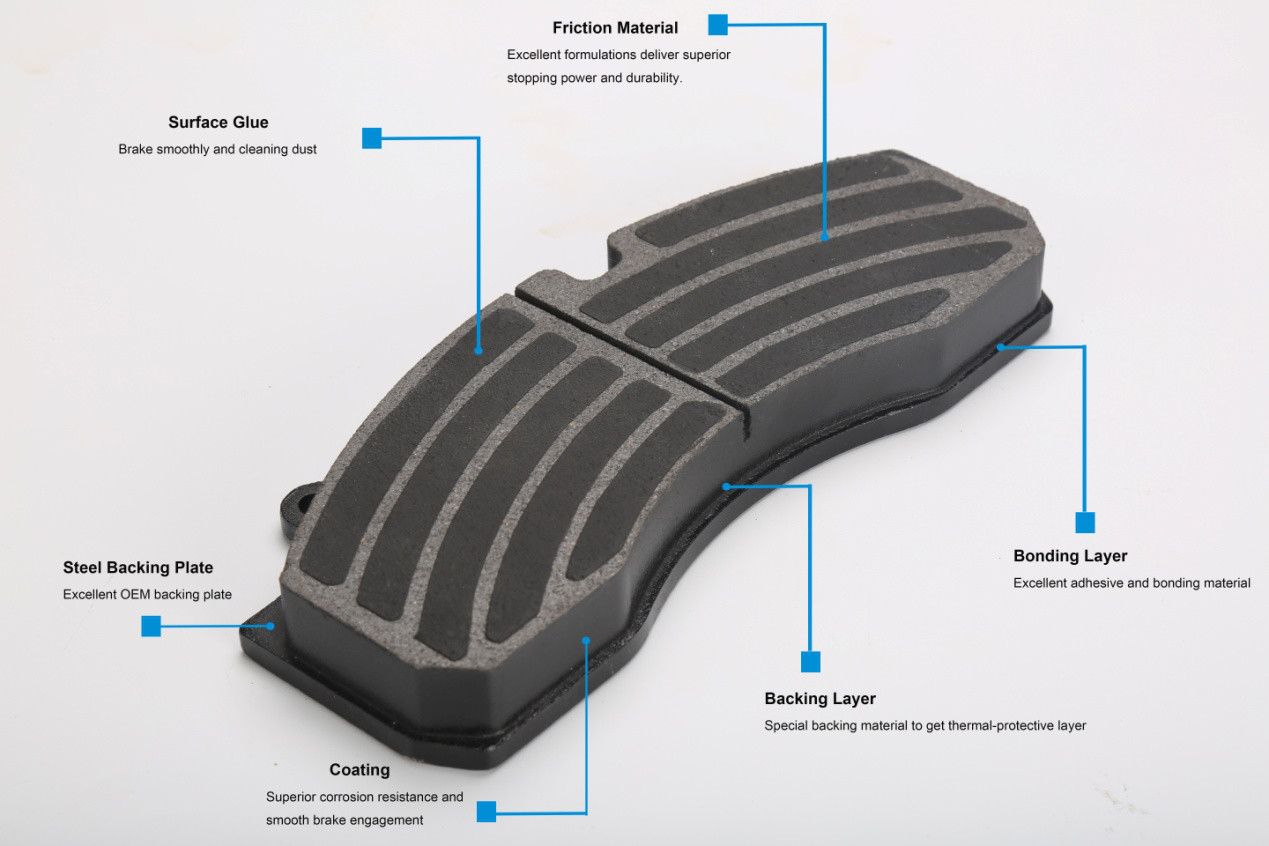

Steel Backing Plate of BAIYUN Bus Prake Pads

Brake Pads of Bus

Brake rotors of disc brakes rotate with the wheels, and brake pads, which are fitted to the brake calipers, clamp on these rotors to stop or decelerate the wheels. The brake pads pushing against the rotors generate friction, which transforms kinetic energy into a thermal energy.

This thermal energy generates heat, but since the main components are exposed to the atmosphere, this heat can be diffused efficiently. This heat-dissipating property reduces brake fade, which is the phenomenon where braking performance is influenced by the heat. Another advantage of disc brakes is its resistance to water fade, which occurs when the water on the brakes significantly reduces braking force. When the vehicle is in motion, the rotor spins at high speeds and this rotational motion discharges the water from the rotors themselves, resulting in stable braking force.

Disc brakes are generally used in passenger cars, but due to their stable performance at higher speeds and resistance to brake fade, they are gradually spreading into the commercial vehicle segment, where drum brakes were traditionally chosen for their longer service life. There is increasing demand from customers for longer service life and higher quality, and Baiyun is committed to meeting them through further development of the disc brake’s reliability. There are two types of disc brakes.

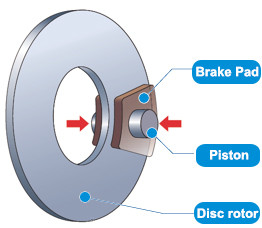

The "opposed piston type disc brake" has pistons on both sides of the disc rotor, while the "floating type disc brake" has a piston on only one side. Floating caliper type disc brakes are also called sliding pin type disc brakes.

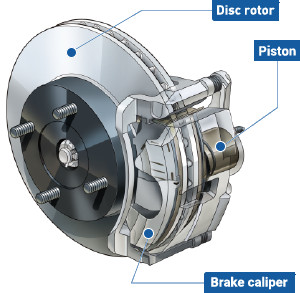

Disc brake construction

The brake rotor (disc) which rotates with the wheel, is clamped by brake pads (friction material) fitted to the caliper from both sides with pressure from the piston(s) (pressure mechanism) and decelerates the disc rotation, thereby slowing down and stopping the vehicle.

How disc brakes work

When the driver steps on the brake pedal, the power is amplified by the brake booster (servo system) and changed into a hydraulic pressure (oil-pressure) by the master cylinder. The pressure reaches the brakes on the wheels via tubing filled with brake oil (brake fluid). The delivered pressure pushes the pistons on the brakes of the four wheels. The pistons in turn press the brake pads, which are friction material, against the brake rotors which rotate with the wheels. The pads clamp on the rotors from both sides and decelerate the wheels, thereby slowing down and stopping the vehicle.

Brake pads for Bus

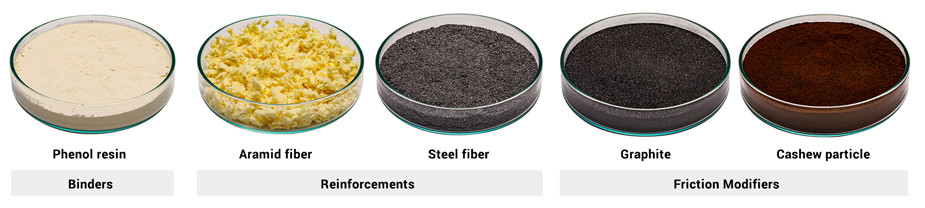

Friction Materials

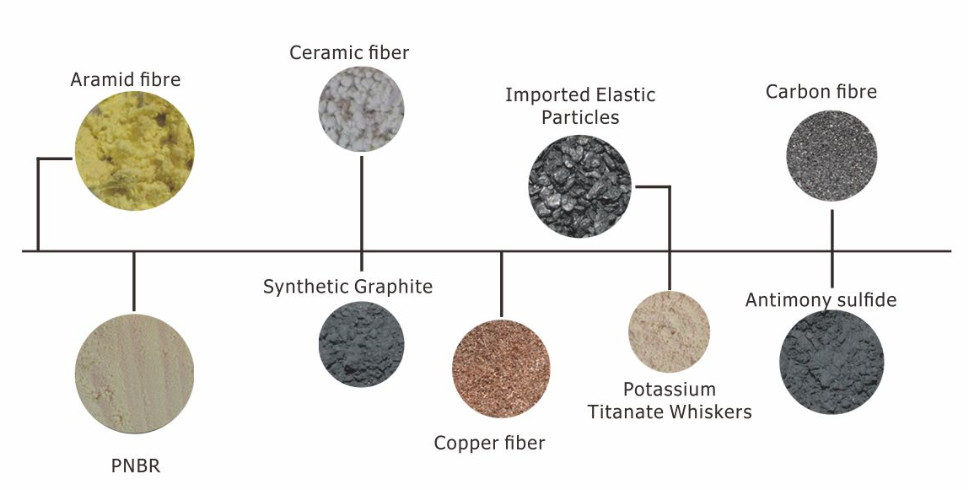

1, Friction Raw Material

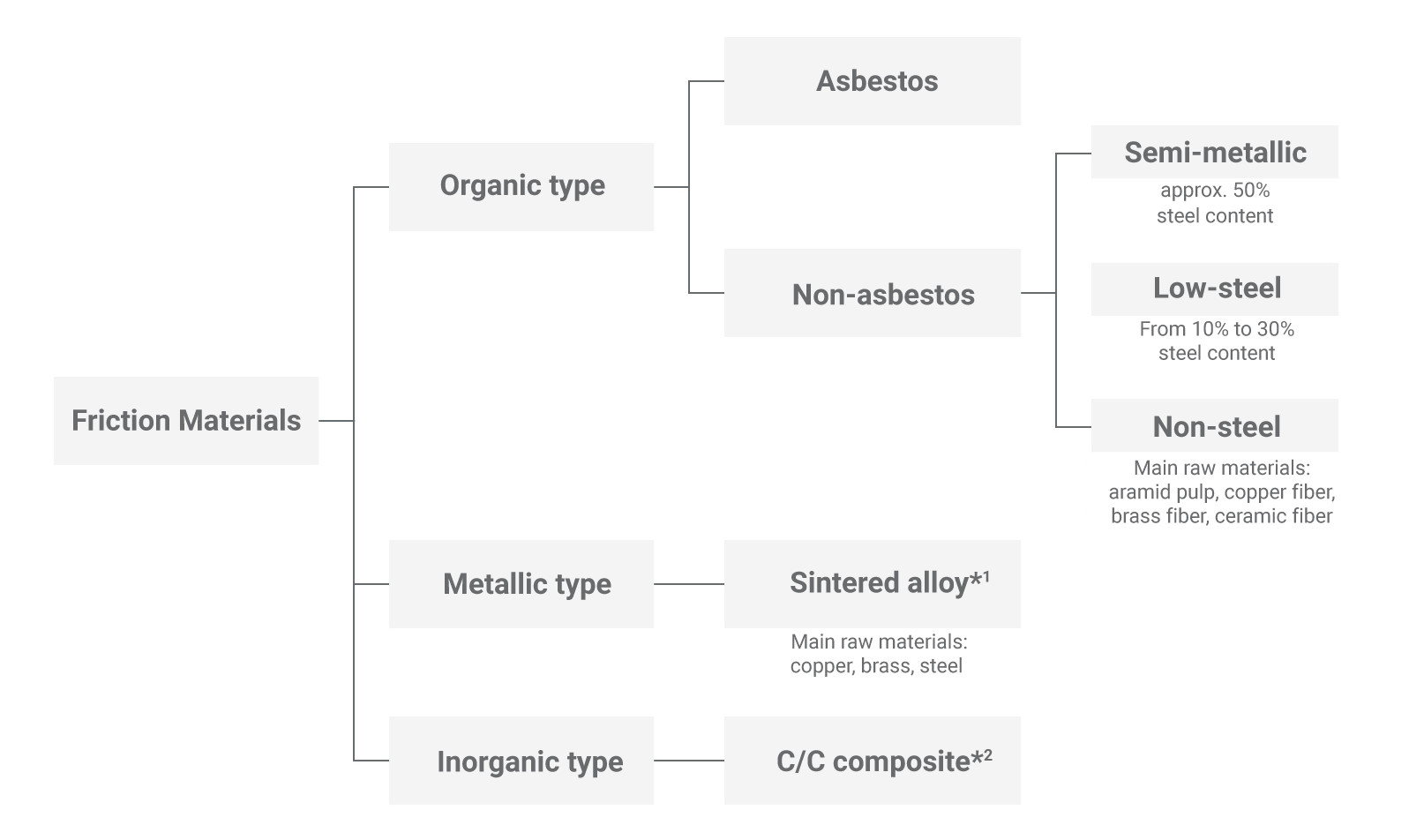

2,Types of friction materials

*1 Sintered alloy: The phenomena where the particles of powder material join together and turns into a solid substance by pressurizing and fabricating the powder material and heating it at temperatures below the melting point. Material that is not made by melting metal, but instead by sintering metal powders is called sintered alloy.

*2 C/C composite: Carbon fiber reinforced carbon composite. Carbon composite material has been strengthened with carbon fiber. It is extremely thermally stable and lightweight. This material is often used for brake rotors and brake pads for aircraft and racing cars.

3, Friction Material of Baiyun

4, Manufacturing process of friction materials