Zhengzhou Baiyun Industrial Co., Ltd. |

|

Yutong Bus Brake Pads 0.35~0.45 Friction Coefficient IATF16949 Quality Control System

| Product name: | E11 certificated truck ceramic brake pads 29087 29175 29174 29171 29125 29246 |

| Dimension: | standard |

| Accessory: | with kits |

| Application | for truck & bus |

| Working life: | 80,000-100,000kms |

| Material: | semi-metallic,ceramic,100% Asbestos-Free |

| Certification | E11 certificated |

| Surface: | Paint,powder coating,electronic paint,etc.According to customer's demand; |

| Coefficient of friction | 0.35-0.45 |

| High friction level at all temperatures,high anti dust capability. | |

| Package | 1.PP bag+individual box+outer carton+pallet; |

| 2.according to requirements, can make customers' brand packing | |

| OEM/ODM | both acceptable |

| Advantages: | all the brake pads non-asbestos, no black dust residue,no pollution, very environmental. |

| stable friction, deliver high stopping power, reliability and safety. | |

| wide range models brake pads for car, buses, trucks | |

| no squealing and excellent stopping power due to our specially formulated friction compound mixture. |

BAIYUN Bus Brake Pads Features

1. Offer OEM brake pad backing plates ,100% superior steel material

2. Good performance brake pad formula ,Non Asbestos

3. A Complete Range Of Specifications and material , Semi-metallic ,low metallic ,Ceramic .

4. No-Noise ,No-Dust ,Long life and at least 50000KM warranty

5. Using Modern Manufacturing Technology And Are Designed To Provide Maximum Safety Even Under Extreme Conditions.

6. Meet International Quality Standards Offering Smooth,Clean Operations With Quiet Performance.

7. Customized Specifications Are welcomed.

8. Sampe are avaiable for you within 7 days once confirmed detalied

BAIYUN STORY

1. Profile

Zhengzhou Baiyun Industrial Co., Ltd., since 1977, is a national high-tech enterprise with main products of brake friction material and brake products. For more than 40 years, Baiyun focus on the R&D, production and selling of brake linings & pads for commercial vehicles and passenger cars, fighting for human traffic braking safety. Till now, Baiyun has become an important supporting supplier and partner of many famous domestic and overseas auto brands. Baiyun has also reached long term strategic cooperation with many famous domestic and overseas auto parts distributors.

Zhengzhou Baiyun Industrial Co., Ltd., is one of the leading auto friction braking enterprise in China, Top 10 enterprises of China Friction Material Industry and member of friction industry association. Baiyun has passed ISO9001 Quality Management System and IATF16949 Auto Industry Quality System Certification. Long-term cooperation is established with international authoritative test organizations such as America LINK and GREEN to test Baiyun brakes regularly. There are more than 1000 models brakes of Baiyun have obtained E-mark certification till now.

Baiyun will insist on the enterprise mission “create value for customers, create happiness for employees” continuously forge ahead, and create a more brilliant future

2. Culture

PHILOSOPHY

Customers are important resources for enterprises to realize sustainable development. Without the needs of customers, enterprises will lose the value of existence. Customer-oriented, put the interests of customers in the first place, with the fastest speed, with the best products and services to meet the needs of customers, to help customers to turn their wishes into reality, is the primary business philosophy.

WORK STYLE

Concentration

Rigorous

Efficient

Cooperation

MISSION

Create value for customers.

Create happiness for employees.

VISION

Innovative technology, to become China's leading auto parts supplier and special equipment manufacturer

Taking advantage of the most modern methods and production resources, and cutting-edge copper-free friction materials, Zhengzhou Baiyun has successfully broken into the market.

The main factors that set Baiyun apart are its extensive product

line, fast launching of new models, and optimum value for money.

Baiyun Brakes’ current formulas use up to 200 different materials to satisfy the market’s needs and the expectations of its customers for all applications.

100% of Baiyun Brakes’ pads are manufactured in accordance with Baiyun Brakes’ strict requirements to comply with regulation R-90, and incorporate a scorching process, which gives them a significant advantage when joining the disk to the pad. The pressing process is carried out with an integrated high-pressure pressing system, which ensures maximum comfort levels for users.

As in the case of brake pads for Commercial Vehicles, NRS technology has been applied in the passenger-car product line, another step in the process to increase the added value of our products.

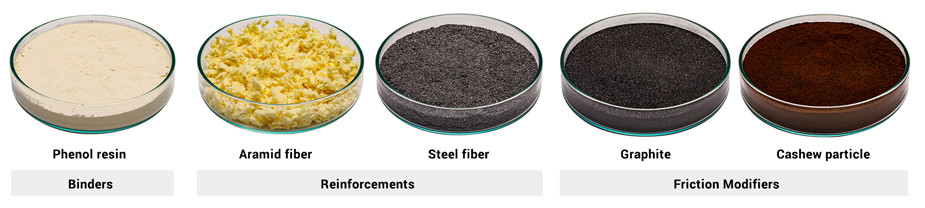

Factors affecting product quality/performance:

1). Formula and materials:

a. What kind of materials are included in the recipe?Is the ratio

of various materials in the formula scientific and reasonable?There

are dozens of commonly used materials such as: Arron, copper fiber,

ceramic fiber, carbon fiber, synthetic graphite, six titanium

potassium acid whisker, powder nitrile, antimony sulfide, etc

b. Purity and quality of materials purchased by the company

2). Components:

The quality of the components used, such as the disc brake sheet's

steel back and muffler, also affects the performance and quality of

the entire brake pad.

3). Processing technology:

a. Control management and protection of materials and components.

b. Pressing effect of pressing process, pressing pressure, whether

it is equal ratio pressing, pressing temperature and duration, etc.

c. Whether the heat treatment temperature and time are appropriate,

and whether the grinding process is fine and standardized.

d. Procedures such as sandblasting and polishing, adhesive coating,

marking and packaging, and control of semi-finished products and

finished products

Baiyun Factory

4. Baiyun R & D

5. Baiyun Workshop