Zhengzhou Baiyun Industrial Co., Ltd. |

|

Top Friction Formulation Car Brake Pad For Passenger Car Front / Rear Brake System With IATF / ISO

BAIYUN Passenger Car Brake Pads

First things first - why do we have different material formulations?

The answer is quite simple, one material cannot cope with the wide

variety of conditions that you will experience whilst riding. As a

brief summary, Organic friction material is the preferred choice

for summer, suited to cross country and leisure riding. it has a

consistant performance across a wide operating range but is not

generally suited to wet and/or harsh environments. Sintered metal

material is a higher friction compound - perfect for demanding

trail riding and a good choice for downhill. It works best with

some heat in the system and revels in wet and gritty conditions. To

learn more about each material click on the tabs above.

With a vast array of friction products available you may have come

across other formulations such as semi-metallic, kevlar or even

dual compound pads amongst other. We routinely test and compare a

wide range of alternative materials and will only bring to market

formulations that meet our exacting standards. Don't beleive claims

about extra long life or that "this material is the best of all

worlds". Different conditions or even riding styles require

different friction materials. Once fitted to a bike, each indivual

pad faces a unique life and longevity is hugely dependent on a

number of circumstances, such as bedding in procedure, riding

environment, cleaning rountine etc.

BAIYUN Auto Brake Pad / Automobile Brake Pad

| Formula | Semi-metallic, Low metallic, Ceramic, High end ceramic, 100% abestos free |

| Shim | Woven shim, Rubber shim |

| Accessories | Barke kits, Brake sensor |

| Color | Dark grey or Customized |

| Price | High-Performance with Reasonbale price |

| Certificates | ISO9001, ISO14001, /IATF16949, E-mark, COP |

| MOQ | 50 sets each item, 1000 sets one order |

| Sample | 1-2 sets with for free |

| Sample Lead time | 7-10 days |

| Car Application | More than 3000 models for different car models |

| EU & USA Car Brands | Mercedes Benz, BMW, AUDI, VW, Ford, Chevrolet, Range Rover, Jeep |

| Japanese Car Brands | Toyota, Nissan,Honda, Mazda, Mitsubishi, Suzuki, Lexus, Subaru, Infiniti |

| Korean Car Brands | Hyundai, Kia, Daweoo |

| Chinese Car Brands | reat Wall, BYD, Haval |

| Order Lead time | 20-30 days |

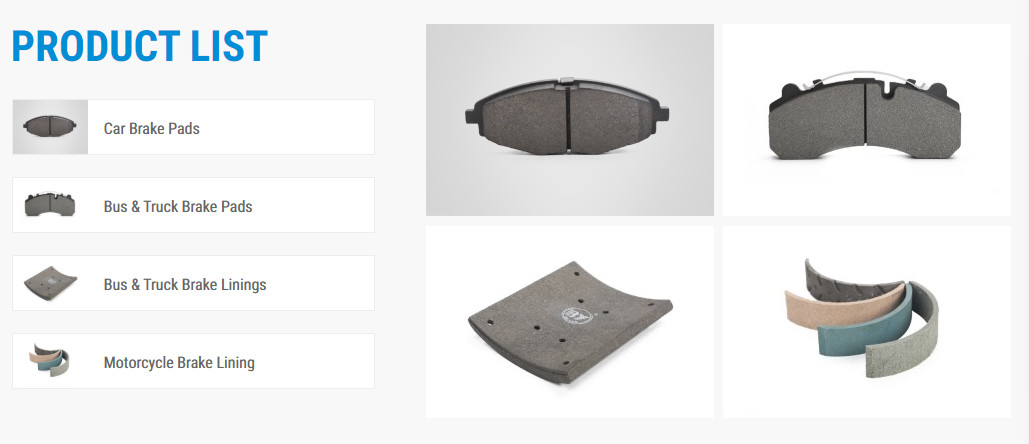

BAIYUN VEHICLES BRAKES

Disc Brake Pad

Drum Brake Lining

Ceramic Brake Pad

Metallic Brake Pad

Commercial Vehicle Brake Pad

Car Brake Pad

Bus Brake Pad

Truck Brake Lining

Motorcycle Brake Lining

Rear Brake Pad

Front Brake Pad

Auto Brake Pad

Friction Brake Pad

Brake Machinery

LIGHT VEHICLE BRAKE PADS

BAIYUN MAKES IT GREENER FOR BEST-IN-CLASS PERFORMANCE WITH THIS

TECHNOLOGICAL BREAKTHROUGH

Green materials for a greener product & a significant reduction

of fine particles emissions

Lower Noise

Much more safety

Best-in-class performance results

AS GREAT AS A BAIYUN PREMIER PAD, MINUS THE COPPER

BAIYUN brake tested on 6 popular vehicles models: consistency of

performance results ascertained

Up to 17% more stopping power than competitors' brands on selected

vehicles makes the BAIYUN pad

the best product with a technical innovation already approved and adopted by vehicle

manufacturers.

WHY CHOOSE BAIYUN CAR BRAKES

Taking advantage of the latest production methods and methods and a new generation of copper-free

friction materials, BAIYUN has successfully entered the market.

The main differentiating factors of BAIYUN are its range, its speed of launching new models and

the optimum value for money.

Today, BAIYUN Brakes formulations use up to 200 different materials to meet market needs and

customer expectations for all applications.

100% of BAIYUN Brakes brake pads are manufactured in accordance with BAIYUN Brakes' premises of

strict compliance with the requirements of regulation R-90 and incorporate the corking process,

which provides a great advantage of coupling the disc to the brake pad. The pressing process is

carried out with an integral pressing system under high pressures, which ensures users the highest

levels of comfort.

ABOUT BAIYUN