High Performance Of Ceramic Bonded CBN Grinding Bits CBN Internal

Grinding Wheel

For Gear Bore Grinding and Other Inner Hole Grinding

Blade Type: TYC-BT-006

The influence of abrasive structure on grinding performance of

grinding wheel:

Abrasive organization is the density of abrasive distribution which

plays a major role in grinding. It can also be said that it is the

volume distribution of abrasive in the abrasive, which is expressed

by the volume percentage of abrasive in the abrasive. The volume percentage of abrasive particles in abrasive tools is

called abrasive rate.

Abrasive particles are the main factors in abrasive tools to cut

the surface of workpiece. The abrasive rate determines the number of abrasive grains per unit

area of the grinding tool in the grinding area, because it greatly

affects the grinding performance and quality of the grinding tool.

We can make customized formula after professional analysis of the

workpiece material, processing parameters and conditions, and processing requirements of customers in the early stage of

grinding wheel design. Especially, the effective number of grains per unit area of

grinding wheel affects a series of grinding performance indexes

such as specific energy, surface quality, grinding heat, grinding

force and grinding efficiency. Therefore, in the manufacturing process of abrasive tools, the

company controls the density of abrasive particle distribution.

The features of the CBN grinding wheel head series:

It is suitable for internal grinding of precision workpiece such as

gear bore and bearing bore

Ceramic bonded CBN grinding wheel has high grinding efficiency and

high workpiece precision;

The structure of the grinding wheel is long, and the service life

of the grinding wheel is not uniform.

Application field and scope:

Machining workpiece:

Automobile steering pump, rotary vane compressor stator;

Piston refrigeration compressor cylinder hole and shaft hole;

Bearing industry, bearing ring grinding;

Constant velocity universal joint ball cage and inner and outer

raceway grinding;

High precision gear bore grinding;

Main features and advantages:

High grinding efficiency,

High machining accuracy,

Good dimensional consistency,

Long service life of grinding wheel

Suitable for grinding materials

Cast iron: chilled cast iron, ball milled cast iron, gray cast

iron, alloy cast iron, etc

Steel parts: 20Cr, GCr15, 45 steel, 55 steel, etc

Our company can customize all kinds of products according to

customers' needs, and establish detailed customer files to ensure

customers' needs. Our company will strictly abide by this commitment and related

contracts, fulfill the responsibilities and obligations!

More Pictures of CBN Grinding Bit :

Brief Introduction of Different Bonded Type of Diamond And CBN

Tools:

- Resin bonded diamond series: resin bonded diamond and cubic boron nitride grinding wheels are

abrasive tools and tools of various shapes made of diamond or cubic

boron nitride and resin bonded.

Features: high grinding efficiency, less heat, good self sharpening, not

easy to block. The surface roughness of

machined workpiece is

low. Such as glass, ceramic.

Applications: widely used in cemented carbide fine grinding, semi fine

grinding, grinding, polishing, porcelain,

stone and other non-metallic

materials fine grinding.

- Diamond bronze bond series: it is an abrasive tool and tool made by pressing and high

temperature sintering with diamond or cubic boron nitride as

abrasive and metal powder as bond.

Features: strong binding force, good wear resistance, long service life,

good shape retention, can withstand heavy load

grinding.

Application: mainly used for grinding and cutting of glass, gem, stone,

semiconductor material, brake pad, and

electrolytic

grinding of cemented carbide.

- Ceramic bonded diamond grinding wheel series:

Features: 1. High edge strength, i.e. high grinding efficiency and good self

sharpening of grinding wheel;

2. Good shape retention; 3. Easy

correction; 4. High durability and long service life of grinding

wheel; 5. High quality

of knife edge.

Purpose: it is mainly used for fast, high efficiency and low loss grinding

of PCD, PCBN, cemented carbide tools and

other cutting tools.

- Diamond / resin cutting chip series:

Diamond cutting chip: mainly used for optical glass, gem, crystal, ceramics, marble,

cemented carbide, tungsten

steel, ferrite, semiconductor, etc.

Diamond resin cutting chip: mainly used for glass, glass tube / plate, gem, crystal, ceramics,

cemented carbide,

tungsten steel, ferrite,

monocrystalline silicon / polycrystalline silicon, silicon rod,

semiconductor, etc

Precautions for use:

Please check carefully before installing the cutting wheel. If

there is any gap or other damage, please stop using it.

When the cutting wheel is marked with the rotation direction, it

should be consistent with the rotation direction of the machine

tool. On the contrary, the cutting is not sharp, and it is difficult to

give full play to the performance of the cutting wheel.

Please do not use the cutting wheel that does not meet the

requirements.

If any abnormality is found in the cutting process, stop the

machine immediately and check the cause.

When the cutting is not sharp, the grinding wheel should be

trimmed. If it is used continuously, the grinding wheel may be damaged due

to overheating and overload.

When the grinding wheel rotates, it is strictly forbidden to cut by

hand, let alone touch the sand by hand and body

The cutting wheel is forbidden to be used in operations other than

grooving or cutting, so as to avoid abnormal operation due to

uneven stress.

Ordering instructions:

When you order for the first time, please provide the following

parameters, so that we can help you choose the most suitable

cutting wheel.

Specification and size: abrasive, particle size, binder, outer

diameter, thickness, inner diameter, abrasive working layer width,

substrate thickness, etc. purpose: workpiece name, cutting size,

cutting material;

Service conditions of grooving and cutting: machine tool, grinding

wheel speed, feed speed and cutting depth;

Dry and wet cutting requirements: cutting accuracy, chipping

requirements, processing surface integrity, etc

Special requirements: whether the tool is assembled and used, whether the resin cutting

wheel needs to conduct electricity, whether the outer circle of the

cutting wheel has a water tank, the size and quantity of the water

tank, whether there is a chip removal groove on the outer side of

the cutting wheel base, etc.

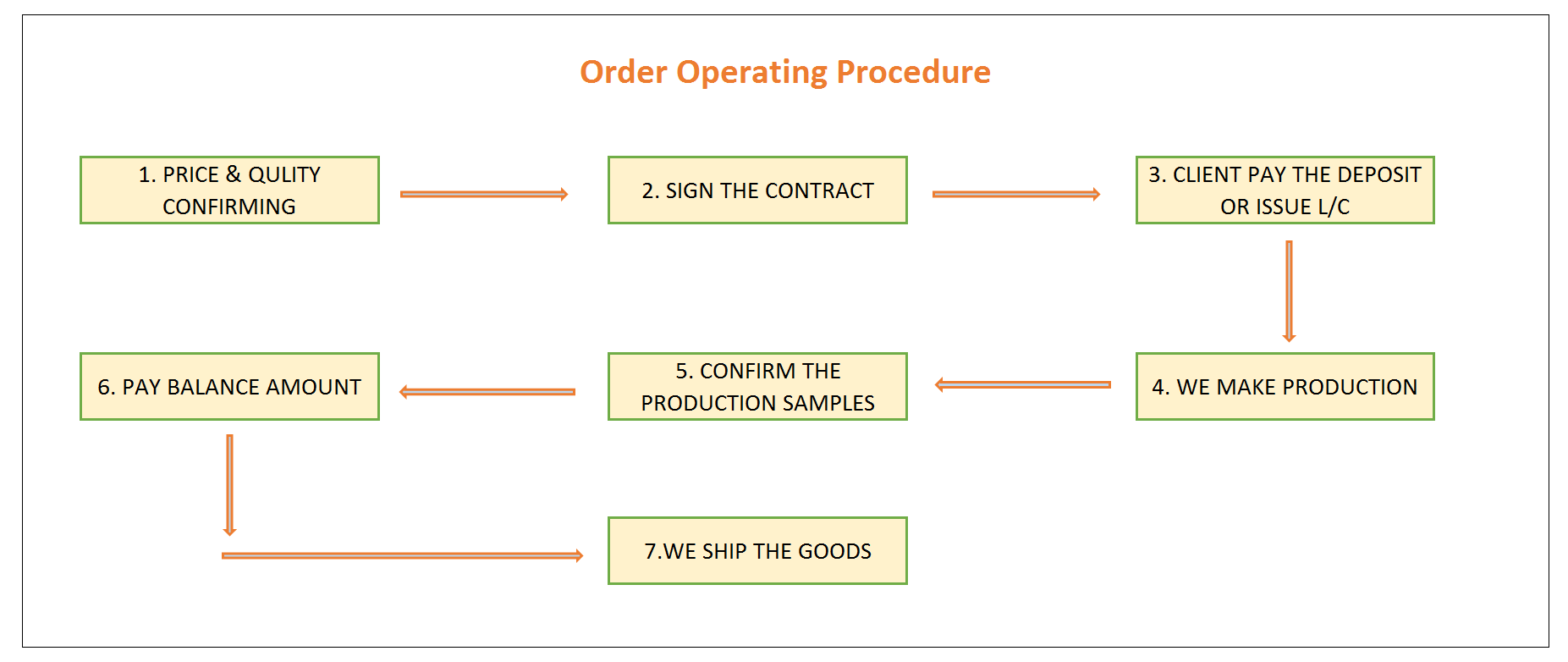

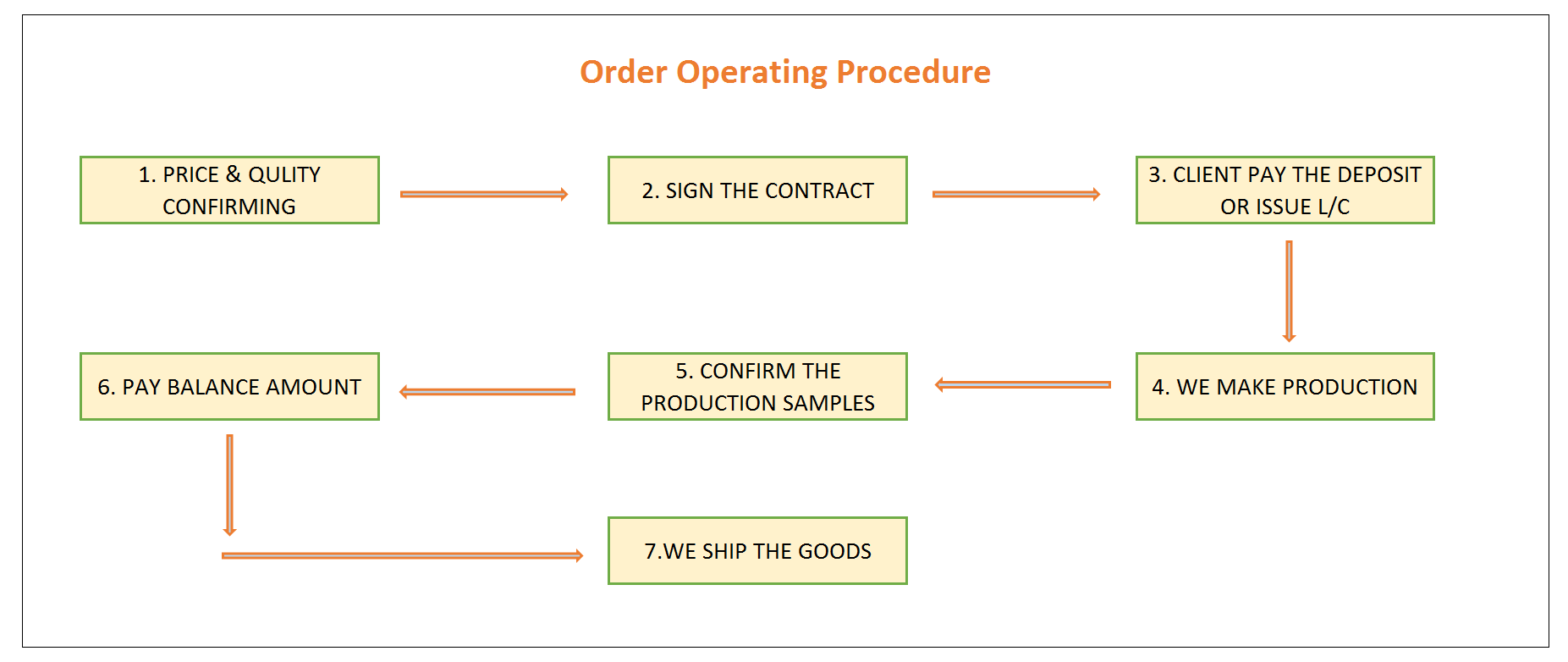

Order Operating Procedure:

FAQ:

Q: Do you accept trial order?

A: Yes, small order is available here.

Q: Do you provide samples ? is it free ?

A: Yes, we could offer the sample free of charge, but clients would

bear for the courier freight charges.

Q: How long is your delivery time?

A: Usually 3 days for ready stocklots. and 5-15 days for new

customed order, it is according to quantity.

Q: What is your terms of payment?

A: T/T, Western Union, Paypal, L/C, others.

Q: Can you provide OEM service?

A: Yes, we can produce the goods with clients' logo and brand.

Over 15 years of developing and producing experience in high

precision super hard material tools, we have

established a high efficiency system to provide stable performance

wheel products.

We welcome yr free inquiry for any question in our diamond cutting

wheels. In order to supply exact wheel

type and quotatioon to you, if possible, better for you to

provide us more information like followings:

1. Yr processing objects.

2. Yr OD, ID, Thickness data.

3. Grit size if possible.

4. Rotary speed of your processing machine.

Many Thanks.