Changzhou Jintan Jinxing Machinery Co., Ltd. |

|

Verified Suppliers

|

|

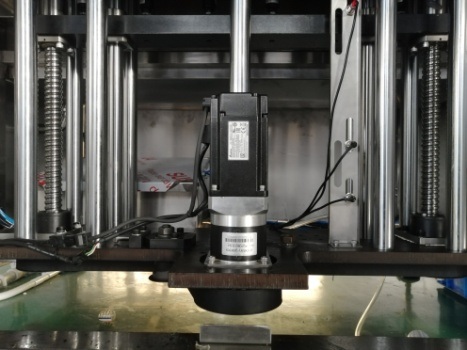

1. Smart equipment, simply place the workpiece and automatically

complete the labeling.It is easy to switch the labels of different

workpieces.

2. Avoid manual labeling, foil inefficient, attached to the skew,

blisters and folds, attached to a series of irregular positions and

other issues.

3. Desktop design, simple structure, small shape, powerful

function.

5. High sensitivity of object and label detection with advanced

electric eye.High labeling accuracy, accuracy deviation ± 1mm

6. Improve product labeling, film attached efficiency, affixed with

accurate location, good quality, high stability; additional

production counting function.

7. Optional distribution function: The code printer / function.

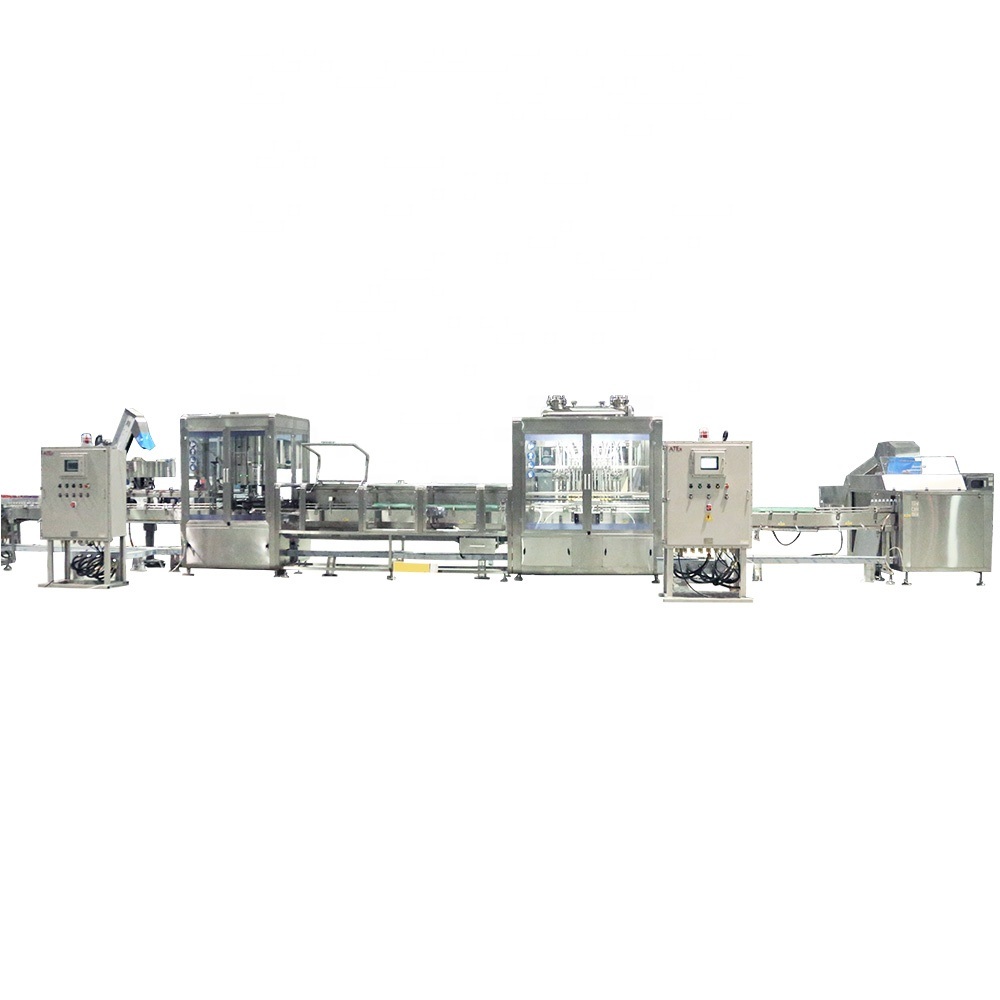

| Filling Nozzle | 4 Nozzle | 6 Nozzle | 8 Nozzle | 10 Nozzle | 12 Nozzle | 16 Nozzle | 18 Nozzle |

| Filling Speed | 30 bot/min | 40 bot/min | 50 bot/min | 60 bot/min | 70 bot/min | 80 bot/min | 90 bot/min |

| Filling Volume | 50-500ml, 100-1000ml | ||||||

| Filling Accuracy | ±0.5-1% | ||||||

| Power Voltage | 220V,50/60Hz,2Phase;380V, 50/60Hz, 3 Phase | ||||||

| Air Consumption | 0.6-0.8Mpa | ||||||

| Remark | 1. Filling speed is 500ml/ bottle of water. 2. Filling speed will be different due to different material characteristics. 3. More options can be customized according to your requirements. | ||||||