ZHEJIANG KAIDI REFRIGERATION EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

Product name: Customized Coolroom Evaporator Freezer Room Air Cooler 380V/3PH/50HZ

ELG SERIES INDUSTRIAL CELLING GLYCOL UNIT COOLERS

1. Product description:

The ELG series industrial ethylene glycol cooler developed by our company adopts φ15 copper tubes, cold storage cooling equipment with glycol aqueous solution as refrigerant. The ELG series of air coolers can be used in cold storage at 10℃, 0℃ and -18℃ respectively.

This series of products have the following characteristics:

● Casing: high quality galvanized steel plate with silver powder coating (RAL7001), with strong corrosion resistance; The two side plates and the outer water plate adopt the hinged structure, which is convenient and fast to operate.

● Evaporator end plate adopts aluminum plate, effectively protect copper tube, reduce weight.

● Double water plate design: the outer water plate adopts angular structure, smooth drainage, no drainage dead angle; The inner water tray adopts the flume structure of aluminum plate. The condensed water or defrosted water is directly discharged into the outlet of the outer water tray through the inner water tray.

● The long air duct design with integral stretch arc has good air flow effect.

● For fan with diameter of 500 and 630, there are floor support feet for easy installation.

● Coil:copper pipe φ15, tube spacing 50×50 square arrangement, heat transfer area is large, heat transfer temperature difference is small, fin frosting speed is slow.

● Corrugated aluminum fins with hydrophilic film, fin spacing of 4.0, 6.0 and 9.0mm to meet the different temperature requirements of cold storage.

● Fan: high-power external rotor fan, operating temperature -30℃~60℃; Fan specificationsφ400,φ500,φ630, the formation of different specifications of the product series, users have more choices.

● Defrosting:standard electric heating defrosting, stainless steel heating pipe are distributed on the coil tube fin and inner water plate, has a good defrosting effect. Water defrosting can also be selected according to customer requirements.

● IP65 grade waterproof junction box and waterproof connector, the fan and heating pipe adopt independent wire box ,with better waterproof effect, high reliability.

● Strict factory pressure test, test pressure 23bar.

2. Standard configuration and options:

| Parts | Configuration | Parts | Configuration | ||

| Casing | Al-Mg alloy sheet with powder coating | × | Fin | Aluminum fins | ○ |

| sheet with powder coating | ○ | Hydrophilic aluminum fins | ● | ||

| Galvanized sheet with powder coating | ● | Defrost | Air defrosting | ○ | |

| Stainless steel plate* | ○ | Electric heating pipe | ● | ||

| Fan | WEIGUANG motor | ● | Water | ○ | |

| EBM motor* | ○ | Drainpipe hot wire | ○ | ||

| The wind bucket motor | ○ | Wind duct heating belt | ○ | ||

●:Standard;○:Options;×:Do not choose.

* : Use short side deflector air duct.

3. Technical data sheet:

3.1 Fin spacing 4.0mm

| Model | Glycol 25% T1=-3℃, T2=2℃ Tr=10℃,RH85% | Glycol 34% T1=-10℃, T2=-7℃ Tr=0℃,RH85% | Surface | Tube Volume | Airflow | Airthrow | Connect pipe | Weight | ||||

| Capa. KW | Flow m3/h | Capa. kw | Flow m3/h | m2 | dm3 | m3/h | m | Inlet | Outlet | Drain | kg | |

| φ400 Fan | ||||||||||||

| ELG401/CL-ET | 5.5 | 1.0 | 3.3 | 1.1 | 26.2 | 4.1 | 3700 | 12 | 28 | 28 | 1" | 49 |

| ELG401/DL-ET | 7.0 | 1.3 | 4.0 | 1.3 | 35.0 | 5.4 | 3200 | 12 | 28 | 28 | 1" | 52 |

| ELG402/CL-ET | 11.0 | 2.0 | 6.6 | 2.1 | 52.5 | 7.5 | 7400 | 13 | 35 | 35 | 1.5" | 72 |

| ELG402/DL-ET | 14.0 | 2.6 | 8.1 | 2.6 | 70.0 | 10.0 | 6400 | 13 | 35 | 35 | 1.5" | 78 |

| ELG403/CL-ET | 16.5 | 3.0 | 9.8 | 3.1 | 78.7 | 11.0 | 11100 | 14 | 35 | 35 | 1.5" | 95 |

| ELG403/DL-ET | 21.0 | 3.9 | 12.1 | 3.9 | 105.0 | 14.6 | 9600 | 14 | 35 | 35 | 1.5" | 104 |

| ELG404/CL-ET | 22.1 | 4.1 | 13.1 | 4.2 | 105.0 | 14.5 | 14800 | 15 | 35 | 35 | 1.5" | 118 |

| ELG404/DL-ET | 28.0 | 5.2 | 16.1 | 5.2 | 140.0 | 19.3 | 12800 | 15 | 42 | 42 | 1.5" | 130 |

| φ500 Fan | ||||||||||||

| ELG501/DL-ET | 12.8 | 2.4 | 7.3 | 2.3 | 61.2 | 9.0 | 6800 | 18 | 35 | 35 | 1.5" | 93 |

| ELG501/EL-ET | 15.3 | 2.8 | 8.4 | 2.7 | 76.5 | 11.2 | 6350 | 17 | 35 | 35 | 1.5" | 99 |

| ELG501/FL-ET | 17.5 | 3.2 | 9.2 | 3.0 | 91.9 | 13.5 | 5500 | 17 | 35 | 35 | 1.5" | 104 |

| ELG502/DL-ET | 25.7 | 4.7 | 14.7 | 4.7 | 122.5 | 17.1 | 13600 | 20 | 42 | 42 | 1.5" | 132 |

| ELG502/EL-ET | 30.6 | 5.6 | 16.8 | 5.4 | 153.1 | 21.3 | 12700 | 19 | 42 | 42 | 1.5" | 143 |

| ELG502/FL-ET | 34.9 | 6.4 | 18.4 | 5.9 | 183.7 | 25.6 | 11000 | 19 | 50 | 50 | 1.5" | 153 |

| ELG503/DL-ET | 38.6 | 7.1 | 22.0 | 7.0 | 183.7 | 25.2 | 20400 | 22 | 50 | 50 | 2" | 180 |

| ELG503/EL-ET | 43.3 | 8.0 | 23.8 | 7.6 | 216.5 | 32.7 | 19050 | 21 | 50 | 50 | 2" | 196 |

| ELG503/FL-ET | 52.4 | 9.6 | 27.6 | 8.8 | 275.6 | 37.8 | 16500 | 21 | 50 | 50 | 2" | 212 |

| ELG504/DL-ET | 51.4 | 9.5 | 29.4 | 9.4 | 244.9 | 33.3 | 27200 | 23 | 50 | 50 | 2" | 228 |

| ELG504/EL-ET | 57.7 | 10.6 | 31.8 | 10.2 | 288.7 | 39.2 | 25400 | 22 | 50 | 50 | 2" | 249 |

| ELG504/FL-ET | 69.8 | 12.8 | 36.7 | 11.8 | 367.4 | 49.9 | 22000 | 22 | 66 | 66 | 2" | 270 |

| ELG505/DL-ET | 64.3 | 11.8 | 36.7 | 11.8 | 306.2 | 41.4 | 34000 | 24 | 66 | 66 | 2" | 276 |

| ELG505/EL-ET | 72.2 | 13.3 | 39.7 | 12.7 | 360.9 | 48.7 | 31750 | 23 | 66 | 66 | 2" | 302 |

| ELG505/FL-ET | 87.3 | 16.1 | 45.9 | 14.7 | 459.3 | 62.0 | 27500 | 23 | 66 | 66 | 2" | 328 |

| φ630 Fan | ||||||||||||

| ELG631/DL-ET | 22.1 | 4.1 | 12.6 | 4.1 | 105.0 | 15.0 | 10000 | 28 | 42 | 42 | 1.5" | 125 |

| ELG631/EL-ET | 26.2 | 4.8 | 14.4 | 4.6 | 131.2 | 18.8 | 9600 | 27 | 42 | 42 | 1.5" | 134 |

| ELG631/FL-ET | 29.9 | 5.5 | 15.7 | 5.0 | 157.5 | 22.5 | 9100 | 27 | 42 | 42 | 1.5" | 143 |

| ELG632/DL-ET | 44.1 | 8.1 | 25.2 | 8.1 | 210.0 | 28.9 | 20000 | 31 | 50 | 50 | 1.5" | 206 |

| ELG632/EL-ET | 52.5 | 9.7 | 28.9 | 9.3 | 262.4 | 36.1 | 19200 | 30 | 50 | 50 | 1.5" | 224 |

| ELG632/FL-ET | 59.8 | 11.0 | 31.5 | 10.1 | 314.9 | 43.3 | 18200 | 30 | 66 | 66 | 1.5" | 242 |

| ELG633/DL-ET | 66.1 | 12.2 | 37.8 | 12.1 | 314.9 | 42.8 | 30000 | 34 | 66 | 66 | 2" | 288 |

| ELG633/EL-ET | 78.7 | 14.5 | 43.3 | 13.9 | 393.7 | 53.4 | 28800 | 33 | 66 | 66 | 2" | 314 |

| ELG633/FL-ET | 89.8 | 16.5 | 47.2 | 15.1 | 472.4 | 64.1 | 27300 | 33 | 66 | 66 | 2" | 341 |

| ELG634/DL-ET | 88.2 | 16.2 | 50.3 | 16.1 | 419.9 | 56.6 | 40000 | 36 | 66 | 66 | 2" | 369 |

| ELG634/EL-ET | 105.0 | 19.4 | 57.7 | 18.5 | 524.9 | 70.8 | 38400 | 35 | 76 | 76 | 2" | 405 |

| ELG634/FL-ET | 119.7 | 22.0 | 63.0 | 20.2 | 629.9 | 84.9 | 36400 | 35 | 76 | 76 | 2" | 440 |

In the table, T1 is the inlet temp. of ethylene glycol solution, T2 is the outlet temp., and Tr is the temp. of cold room.

3.2 Fin spacing 6.0mm

| 型号 | Glycol 34% T1=-10℃, T2=-7℃ Tr=0℃,RH85% | Glycol 50% T1=-28℃,T2=-25℃ Tr=-18℃,RH95% | Surface | Tube Volume | Airflow | Airthrow | Connect pipe | Weight | ||||

| Capa. KW | Flow m3/h | Capa. KW | Flow m3/h | m2 | dm3 | m3/h | m | Inlet | Outlet | Drain | kg | |

| φ400 Fan | ||||||||||||

| ELG401/CD-ET | 3.0 | 1.0 | 2.5 | 0.9 | 17.8 | 4.1 | 3800 | 13 | 28 | 28 | 1" | 47 |

| ELG401/DD-ET | 3.8 | 1.3 | 3.1 | 1.1 | 23.7 | 5.4 | 3450 | 13 | 28 | 28 | 1" | 50 |

| ELG402/CD-ET | 6.1 | 2.0 | 5.0 | 1.8 | 35.6 | 7.5 | 7600 | 14 | 35 | 35 | 1.5" | 69 |

| ELG402/DD-ET | 7.6 | 2.5 | 6.2 | 2.2 | 47.5 | 10.0 | 6900 | 14 | 35 | 35 | 1.5" | 74 |

| ELG403/CD-ET | 9.1 | 3.0 | 7.5 | 2.6 | 53.4 | 11.0 | 11400 | 15 | 35 | 35 | 1.5" | 90 |

| ELG403/DD-ET | 11.4 | 3.7 | 9.3 | 3.3 | 71.2 | 14.6 | 10350 | 15 | 35 | 35 | 1.5" | 98 |

| ELG404/CD-ET | 12.1 | 4.0 | 10.0 | 3.5 | 71.2 | 14.5 | 15200 | 16 | 35 | 35 | 1.5" | 112 |

| ELG404/DD-ET | 15.2 | 5.0 | 12.3 | 4.3 | 94.9 | 19.3 | 13800 | 16 | 42 | 42 | 1.5" | 122 |

| φ500 Fan | ||||||||||||

| ELG501/DD-ET | 7.1 | 2.3 | 5.4 | 1.9 | 41.5 | 9.0 | 7000 | 19 | 35 | 35 | 1.5" | 90 |

| ELG501/ED-ET | 8.3 | 2.7 | 6.2 | 2.2 | 51.9 | 11.2 | 6500 | 18 | 35 | 35 | 1.5" | 94 |

| ELG501/FD-ET | 9.3 | 3.0 | 6.9 | 2.5 | 62.3 | 13.5 | 6100 | 18 | 35 | 35 | 1.5" | 99 |

| ELG502/DD-ET | 14.1 | 4.5 | 10.8 | 3.8 | 83.1 | 17.1 | 14000 | 21 | 42 | 42 | 1.5" | 126 |

| ELG502/ED-ET | 16.6 | 5.4 | 12.5 | 4.4 | 103.8 | 21.3 | 13000 | 20 | 42 | 42 | 1.5" | 134 |

| ELG502/FD-ET | 18.7 | 6.0 | 13.7 | 4.8 | 124.6 | 25.6 | 12200 | 20 | 50 | 50 | 1.5" | 143 |

| ELG503/DD-ET | 21.2 | 6.8 | 16.2 | 5.7 | 124.6 | 25.2 | 21000 | 23 | 50 | 50 | 2" | 170 |

| ELG503/ED-ET | 23.5 | 7.5 | 17.6 | 6.2 | 146.8 | 32.7 | 19500 | 22 | 50 | 50 | 2" | 183 |

| ELG503/FD-ET | 28.0 | 9.0 | 20.6 | 7.2 | 186.9 | 37.8 | 18300 | 22 | 50 | 50 | 2" | 196 |

| ELG504/DD-ET | 28.2 | 9.0 | 21.6 | 7.6 | 166.1 | 33.3 | 28000 | 24 | 50 | 50 | 2" | 215 |

| ELG504/ED-ET | 31.3 | 10.0 | 23.5 | 8.3 | 195.8 | 39.2 | 26000 | 23 | 50 | 50 | 2" | 232 |

| ELG504/FD-ET | 37.4 | 12.0 | 27.4 | 9.6 | 249.2 | 49.9 | 24400 | 23 | 66 | 66 | 2" | 250 |

| ELG505/DD-ET | 35.3 | 11.3 | 27.0 | 9.5 | 207.6 | 41.4 | 35000 | 25 | 66 | 66 | 2" | 259 |

| ELG505/ED-ET | 39.2 | 12.5 | 29.4 | 10.3 | 244.7 | 48.7 | 32500 | 24 | 66 | 66 | 2" | 281 |

| ELG505/FD-ET | 46.7 | 15.0 | 34.3 | 12.0 | 311.5 | 62.0 | 30500 | 24 | 66 | 66 | 2" | 303 |

| φ630 Fan | ||||||||||||

| ELG631/DD-ET | 12.1 | 3.9 | 9.3 | 3.3 | 71.2 | 15.0 | 10300 | 29 | 42 | 42 | 1.5" | 119 |

| ELG631/ED-ET | 14.2 | 4.6 | 10.7 | 3.8 | 89.0 | 18.8 | 9800 | 28 | 42 | 42 | 1.5" | 126 |

| ELG631/FD-ET | 16.0 | 5.2 | 11.7 | 4.1 | 106.8 | 22.5 | 9100 | 28 | 42 | 42 | 1.5" | 134 |

| ELG632/DD-ET | 24.2 | 7.8 | 18.5 | 6.5 | 142.4 | 28.9 | 20600 | 32 | 50 | 50 | 1.5" | 194 |

| ELG632/ED-ET | 28.5 | 9.2 | 21.4 | 7.5 | 178.0 | 36.1 | 19600 | 31 | 50 | 50 | 1.5" | 209 |

| ELG632/FD-ET | 32.0 | 10.3 | 23.5 | 8.3 | 213.6 | 43.3 | 18200 | 31 | 66 | 66 | 1.5" | 224 |

| ELG633/DD-ET | 36.3 | 11.7 | 27.8 | 9.8 | 213.6 | 42.8 | 30900 | 35 | 66 | 66 | 2" | 270 |

| ELG633/ED-ET | 42.7 | 13.7 | 32.0 | 11.2 | 267.0 | 53.4 | 29400 | 34 | 66 | 66 | 2" | 292 |

| ELG633/FD-ET | 48.1 | 15.4 | 35.2 | 12.4 | 320.4 | 64.1 | 27300 | 34 | 66 | 66 | 2" | 315 |

| ELG634/DD-ET | 48.4 | 15.5 | 37.0 | 13.0 | 284.8 | 56.6 | 41200 | 37 | 66 | 66 | 2" | 346 |

| ELG634/ED-ET | 57.0 | 18.3 | 42.7 | 15.0 | 356.0 | 70.8 | 39200 | 36 | 76 | 76 | 2" | 375 |

| ELG634/FD-ET | 64.1 | 20.5 | 47.0 | 16.5 | 427.2 | 84.9 | 36400 | 36 | 76 | 76 | 2" | 405 |

In the table, T1 is the inlet temp. of ethylene glycol solution, T2 is the outlet temp., and Tr is the temp. of cold room.

3.3 Fin spacing 9.0mm

| Model | Glycol 34% T1=-10℃, T2=-7℃ Tr=0℃,RH85% | Glycol 50% T1=-28℃,T2=-25℃ Tr=-18℃,RH95% | Surface | Tube Volume | Airflow | Airthrow | Connect pipe | Weight | ||||

| Capa. KW | Flow m3/h | Capa. KW | Flow m3/h | m2 | dm3 | m3/h | m | Inlet | Outlet | Drain | kg | |

| φ400 Fan | ||||||||||||

| ELG401/CJ-ET | 2.4 | 0.8 | 2.0 | 0.7 | 12.2 | 4.1 | 3900 | 14 | 28 | 28 | 1" | 47 |

| ELG401/DJ-ET | 3.1 | 1.0 | 2.5 | 0.9 | 16.2 | 5.4 | 3650 | 14 | 28 | 28 | 1" | 50 |

| ELG402/CJ-ET | 4.9 | 1.6 | 4.1 | 1.5 | 24.4 | 7.5 | 7800 | 15 | 35 | 35 | 1.5" | 68 |

| ELG402/DJ-ET | 6.2 | 2.0 | 5.2 | 1.9 | 32.5 | 10.0 | 7300 | 15 | 35 | 35 | 1.5" | 73 |

| ELG403/CJ-ET | 7.3 | 2.4 | 6.2 | 2.2 | 36.5 | 11.0 | 11700 | 16 | 35 | 35 | 1.5" | 89 |

| ELG403/DJ-ET | 9.2 | 3.0 | 7.8 | 2.8 | 48.7 | 14.6 | 10950 | 16 | 35 | 35 | 1.5" | 97 |

| ELG404/CJ-ET | 9.7 | 3.1 | 8.3 | 2.9 | 48.7 | 14.5 | 15600 | 17 | 35 | 35 | 1.5" | 111 |

| ELG404/DJ-ET | 12.4 | 4.0 | 10.4 | 3.7 | 65.0 | 19.3 | 14600 | 17 | 42 | 42 | 1.5" | 120 |

| φ500 Fan | ||||||||||||

| ELG501/DJ-ET | 5.4 | 1.8 | 4.5 | 1.6 | 28.4 | 9.0 | 7380 | 20 | 35 | 35 | 1.5" | 89 |

| ELG501/EJ-ET | 6.4 | 2.1 | 5.3 | 1.9 | 35.5 | 11.2 | 6800 | 19 | 35 | 35 | 1.5" | 93 |

| ELG501/FJ-ET | 7.2 | 2.3 | 6.0 | 2.1 | 42.6 | 13.5 | 6350 | 19 | 35 | 35 | 1.5" | 98 |

| ELG502/DJ-ET | 10.8 | 3.5 | 9.1 | 3.2 | 56.9 | 17.1 | 14760 | 22 | 42 | 42 | 1.5" | 124 |

| ELG502/EJ-ET | 12.8 | 4.1 | 10.7 | 3.8 | 71.1 | 21.3 | 13600 | 21 | 42 | 42 | 1.5" | 132 |

| ELG502/FJ-ET | 14.5 | 4.7 | 11.9 | 4.2 | 85.3 | 25.6 | 12700 | 21 | 50 | 50 | 1.5" | 141 |

| ELG503/DJ-ET | 16.2 | 5.2 | 13.6 | 4.8 | 85.3 | 25.2 | 22140 | 24 | 50 | 50 | 2" | 168 |

| ELG503/EJ-ET | 18.1 | 5.8 | 15.1 | 5.3 | 100.5 | 32.7 | 20400 | 23 | 50 | 50 | 2" | 180 |

| ELG503/FJ-ET | 21.7 | 7.0 | 17.9 | 6.3 | 127.9 | 37.8 | 19050 | 23 | 50 | 50 | 2" | 193 |

| ELG504/DJ-ET | 21.6 | 7.0 | 18.2 | 6.4 | 113.7 | 33.3 | 29520 | 25 | 50 | 50 | 2" | 212 |

| ELG504/EJ-ET | 24.1 | 7.8 | 20.1 | 7.0 | 134.0 | 39.2 | 27200 | 24 | 50 | 50 | 2" | 228 |

| ELG504/FJ-ET | 29.0 | 9.3 | 23.9 | 8.4 | 170.6 | 49.9 | 25400 | 24 | 66 | 66 | 2" | 245 |

| ELG505/DJ-ET | 27.0 | 8.7 | 22.7 | 8.0 | 142.1 | 41.4 | 36900 | 26 | 66 | 66 | 2" | 256 |

| ELG505/EJ-ET | 30.2 | 9.7 | 25.1 | 8.8 | 167.5 | 48.7 | 34000 | 25 | 66 | 66 | 2" | 276 |

| ELG505/FJ-ET | 36.2 | 11.6 | 29.8 | 10.5 | 213.2 | 62.0 | 31750 | 25 | 66 | 66 | 2" | 297 |

| φ630 Fan | ||||||||||||

| ELG631/DJ-ET | 9.3 | 3.0 | 7.8 | 2.8 | 48.7 | 15.0 | 10600 | 30 | 42 | 42 | 1.5" | 118 |

| ELG631/EJ-ET | 11.0 | 3.6 | 9.1 | 3.2 | 60.9 | 18.8 | 10000 | 29 | 42 | 42 | 1.5" | 125 |

| ELG631/FJ-ET | 12.4 | 4.0 | 10.2 | 3.6 | 73.1 | 22.5 | 9600 | 29 | 42 | 42 | 1.5" | 132 |

| ELG632/DJ-ET | 18.5 | 6.0 | 15.6 | 5.5 | 97.5 | 28.9 | 21200 | 33 | 50 | 50 | 1.5" | 192 |

| ELG632/EJ-ET | 21.9 | 7.0 | 18.3 | 6.5 | 121.8 | 36.1 | 20000 | 32 | 50 | 50 | 1.5" | 206 |

| ELG632/FJ-ET | 24.9 | 8.0 | 20.5 | 7.2 | 146.2 | 43.3 | 19200 | 32 | 66 | 66 | 1.5" | 220 |

| ELG633/DJ-ET | 27.8 | 9.0 | 23.4 | 8.2 | 146.2 | 42.8 | 31800 | 36 | 66 | 66 | 2" | 266 |

| ELG633/EJ-ET | 32.9 | 10.5 | 27.4 | 9.6 | 182.7 | 53.4 | 30000 | 35 | 66 | 66 | 2" | 282 |

| ELG633/FJ-ET | 37.3 | 12.0 | 30.7 | 10.8 | 219.3 | 64.1 | 28800 | 35 | 66 | 66 | 2" | 309 |

| ELG634/DJ-ET | 37.0 | 12.0 | 31.2 | 10.9 | 194.9 | 56.6 | 42400 | 38 | 66 | 66 | 2" | 340 |

| ELG634/EJ-ET | 43.8 | 14.0 | 36.5 | 12.8 | 243.6 | 70.8 | 40000 | 37 | 76 | 76 | 2" | 369 |

| ELG634/FJ-ET | 49.7 | 16.0 | 40.9 | 14.5 | 292.4 | 84.9 | 38400 | 37 | 76 | 76 | 2" | 397 |

In the table, T1 is the inlet temp. of ethylene glycol solution, T2 is the outlet temp., and Tr is the temp. of cold room.

4. Electrical parameter table:

| Model | Fan motor | Electric defrosting | |||||

| Voltage(V) | Input(W) | Current(A) | Speed(r/min) | Coil(KW) | Tray(KW) | Total(KW) | |

| ELG401/C* | 380-3 | 205 | 0.51 | 1380 | 3×0.6 | 1×0.6 | 2.4 |

| ELG401/D* | 380-3 | 205 | 0.51 | 1380 | 4×0.6 | 1×0.6 | 3.0 |

| ELG402/C* | 380-3 | 410 | 1.02 | 1380 | 3×1.1 | 1×1.1 | 4.4 |

| ELG402/D* | 380-3 | 410 | 1.02 | 1380 | 4×1.1 | 1×1.1 | 5.5 |

| ELG403/C* | 380-3 | 615 | 1.53 | 1380 | 3×1.6 | 1×1.6 | 6.4 |

| ELG403/D* | 380-3 | 615 | 1.53 | 1380 | 4×1.6 | 1×1.6 | 8.0 |

| ELG404/C* | 380-3 | 820 | 2.04 | 1380 | 3×2.0 | 1×2.0 | 8.0 |

| ELG404/D* | 380-3 | 820 | 2.04 | 1380 | 4×2.0 | 1×2.0 | 10.0 |

| ELG501/D* | 380-3 | 500 | 0.95 | 1380 | 4×0.8 | 2×0.8 | 4.8 |

| ELG501/E* | 380-3 | 500 | 0.95 | 1380 | 6×0.8 | 2×0.8 | 6.4 |

| ELG501/F* | 380-3 | 500 | 0.95 | 1380 | 6×0.8 | 2×0.8 | 6.4 |

| ELG502/D* | 380-3 | 1000 | 1.9 | 1380 | 4×1.6 | 2×1.6 | 9.6 |

| ELG502/E* | 380-3 | 1000 | 1.9 | 1380 | 6×1.6 | 2×1.6 | 12.8 |

| ELG502/F* | 380-3 | 1000 | 1.9 | 1380 | 6×1.6 | 2×1.6 | 12.8 |

| ELG503/D* | 380-3 | 1500 | 2.85 | 1380 | 4×2.3 | 2×2.3 | 13.8 |

| ELG503/E* | 380-3 | 1500 | 2.85 | 1380 | 6×2.3 | 2×2.3 | 18.4 |

| ELG503/F* | 380-3 | 1500 | 2.85 | 1380 | 6×2.3 | 2×2.3 | 18.4 |

| ELG504/D* | 380-3 | 2000 | 3.8 | 1380 | 4×3.0 | 2×3.0 | 18.0 |

| ELG504/E* | 380-3 | 2000 | 3.8 | 1380 | 6×3.0 | 2×3.0 | 24.0 |

| ELG504/F* | 380-3 | 2000 | 3.8 | 1380 | 6×3.0 | 2×3.0 | 24.0 |

| ELG505/D* | 380-3 | 2500 | 4.75 | 1380 | 4×3.7 | 2×3.7 | 22.2 |

| ELG505/E* | 380-3 | 2500 | 4.75 | 1380 | 6×3.7 | 2×3.7 | 29.6 |

| ELG505/F* | 380-3 | 2500 | 4.75 | 1380 | 6×3.7 | 2×3.7 | 29.6 |

| ELG631/D* | 380-3 | 800 | 1.6 | 1320 | 6×1.1 | 2×1.1 | 8.8 |

| ELG631/E* | 380-3 | 800 | 1.6 | 1320 | 9×1.1 | 2×1.1 | 12.1 |

| ELG631/F* | 380-3 | 800 | 1.6 | 1320 | 9×1.1 | 2×1.1 | 12.1 |

| ELG632/D* | 380-3 | 1600 | 3.2 | 1320 | 6×2.0 | 2×2.0 | 16.0 |

| ELG632/E* | 380-3 | 1600 | 3.2 | 1320 | 9×2.0 | 2×2.0 | 22.0 |

| ELG632/F* | 380-3 | 1600 | 3.2 | 1320 | 9×2.0 | 2×2.0 | 22.0 |

| ELG633/D* | 380-3 | 2400 | 4.8 | 1320 | 6×3.0 | 2×3.0 | 24.0 |

| ELG633/E* | 380-3 | 2400 | 4.8 | 1320 | 9×3.0 | 2×3.0 | 33.0 |

| ELG633/F* | 380-3 | 2400 | 4.8 | 1320 | 9×3.0 | 2×3.0 | 33.0 |

| ELG634/D* | 380-3 | 3200 | 6.4 | 1320 | 6×4.0 | 2×4.0 | 32.0 |

| ELG634/E* | 380-3 | 3200 | 6.4 | 1320 | 9×4.0 | 2×4.0 | 44.0 |

| ELG634/F* | 380-3 | 3200 | 6.4 | 1320 | 9×4.0 | 2×4.0 | 44.0 |

5.How to select correct evaparator:

Generally,Choose evaporator capacity=cold room cooling capacity *1.15

1.When the cold room temperature is around 0℃, select 4.5mm as fin space.

Evaporator choose=1.0*Q0

2.When the cold room temperature is around -18℃, select 6mm as fin space.

Evaparator choose=1.1*Q0

3.When the cold room temperature is around -25℃, select 9mm as fin space.

Evaparator choose=1.27*Q0

Remarks: The water defrost and hot gas defrost type are also optional.

Customized specification leave me message for details.

6.Want to know other related products?-click picture for detailed specification

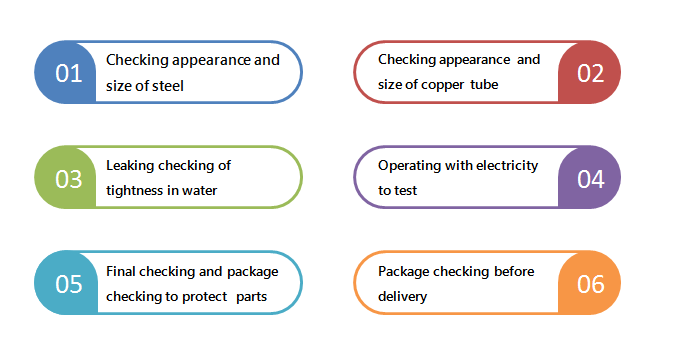

7.How to assure quality? Any procedure?

Our QC department will make sure of each step

8.Do you factory?

We are factory established in 1995 and through 28years developed,welcomed by all our customers.Because of all your support now we are a big family of more than 300 people,covered 50000 square meters,and your supporting is very important of continuing our dream of eating fresh and healthy food.

9.Do you attend exhibition?

Each year we will attend domestic national and foreign exhibition,also we will support our agent to attend exhibition,welcome to join us.

10.Why choose us

Professional:28 years focus one thing-refrigeration equipments

Material we use sufficient

Certificate:CE, ISO, and cetiifcate of producing special pressure equipment

11.Projects reference?

12.FAQ

1, Q:Where is your factory address?

A:We are factory and located in refrigeration equipment producing base Shengzhou,Zhejiang province.

2, Q: What is your package?

A: Our package comply to custom require not include original wood.

3, Q:What is your MOQ?

A: Ordinary products can order from 1 set.

4, Q: Can you offer sample?

A: Yes,we can offer sample.and cost and delivery at your charge.

5, Q:I can't find products on your list?

A: Please contact me directly.

6,Q:How can i confirm your factory?

A: We have third party verified document of Bureau Veritas report,you can download in company page or leave me message to get.