Wuxi Techwell Machinery Co., Ltd |

|

Verified Suppliers

|

|

2.0-3.0mm Heavy Duty Upright Racking / Shelf Roll Forming Machine with JH21-80 Ton Press Machine To Punch Holes

After-sales Service Provided | Engineers available to service machinery overseas |

Raw material | Steel Coil gi ppgi |

Control system | PLC(imported Brand) |

Shafter material | 40Cr |

Cutting type | Automatic Hydraulic Cutting |

Cutting blade material | cr12 with quenched treatment |

Color of Machine | Blue or Customer request |

Roller Station | 14 Stations |

Forming Speed | 16-20m/min |

A). Main Specifications

1). 4 Ton Manual Uncoiler

|

2). 7 Roller Leveling Machine

|

3). Servo Feeding Machine

|

4). JH21-80 Press Machine

|

5). Main Upright Racking Roll Forming Machine

|

6). Hydraulic Cutting & Hydraulic Station

|

7). PLC Control System

|

8). Run-out Table

|

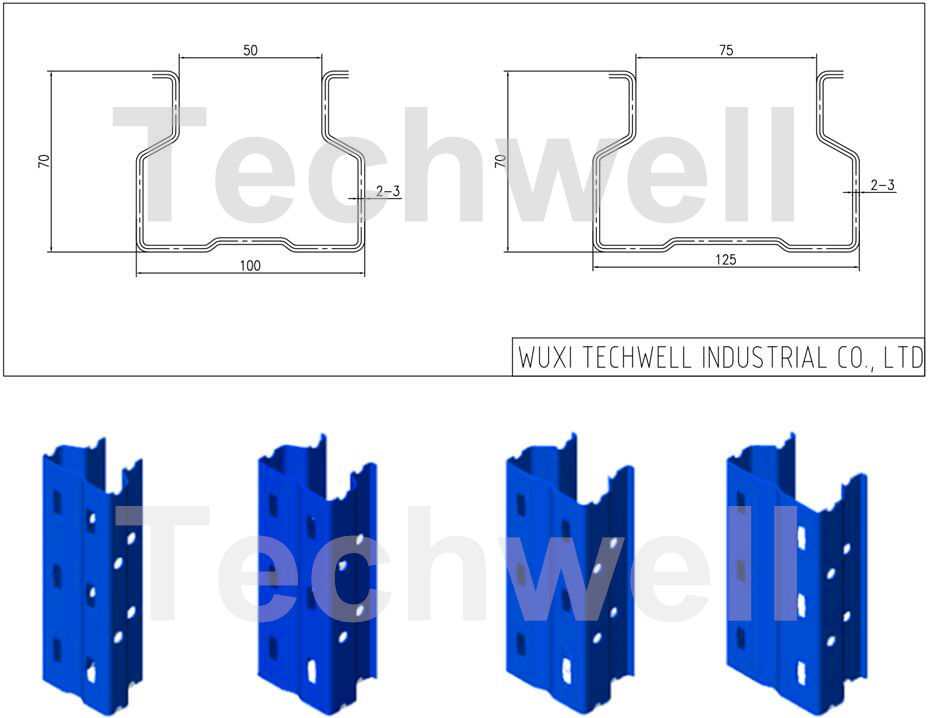

B). Upright Rack Work Piece Profile Drawing

C). Layout of Cable Tray Forming Machine

D). Main Components

| Components of Upright Rack Roll Forming Machine | Quantity |

| 4 Ton Uncoiler | 1 Unit |

| 7 Rollers Leveling | 1 Unit |

| Servo Feeding | 1 Unit |

| JH21-80 Press Machine | 1 Unit |

| Main Roll Forming Machine | 1 Unit |

| Hydraulic Cutting | 1 Unit |

| PLC Electrical Control Board | 1 Unit |

| Hydraulic Stations | 1 Unit |

| Run Out Table | 1 Unit |

E). More Photos of Upright Racking Roll Forming Machine

F). Contacts of WUXI TECHWELL

| Company | Wuxi Techwell Machinery Co., Ltd Wuxi Techwell Industrial Co., Ltd |

| Website | www.cold-rollformingmachine.com |

| www.roofrollformingmachine.com | |

| www.wxtechwell.com | |

| Video | www.youtube.com/wxtechwell |

| Tel / Fax | 0086-510-83133431 |

| Mobile / Whatsapp | 0086-18018304331 ( Monica ) |

| monica@wxtechwell.com | |

| Skype | monica198614 |