Wuxi Techwell Machinery Co., Ltd |

|

Verified Suppliers

|

|

18 Groups Forming Roller Stand Upright Rack Roll Forming Machine for Storage Rack

Main Specifications Of Upright Rack Roll Forming Machine

1). 4 Ton Manual Uncoiler

2). 7 Roller Leveling Machine

3). Servo Feeding Machine

4). Press Machine

5). Main Upright Racking Roll Forming Machine

6). Hydraulic Cutting & Hydraulic Station

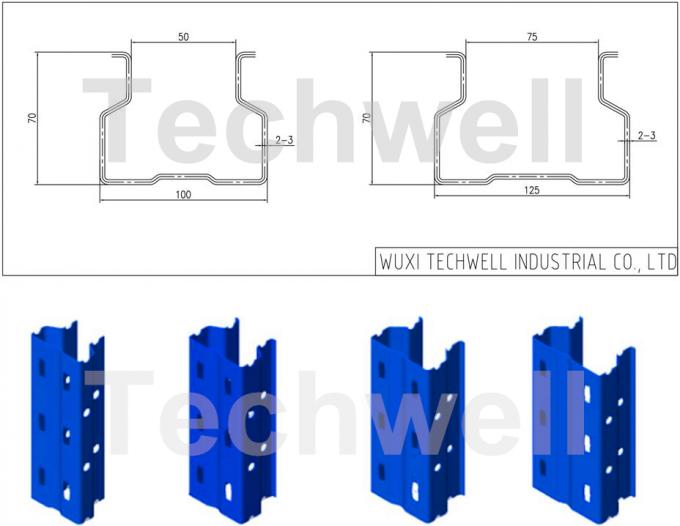

Rack Profile Drawings

Working Flow

Decoiler ---- Leveling ----- Servo Feeding --- Press Machine

--- Roll Forming ---- Cutting ---- Run out tables

Main Components

| Components of Upright Rack Roll Forming Machine | Quantity |

| 4 Ton Uncoiler | 1 Unit |

| 7 Rollers Leveling | 1 Unit |

| Servo Feeding | 1 Unit |

| Press Machine | 1 Unit |

| Main Roll Forming Machine | 1 Unit |

| Hydraulic Cutting | 1 Unit |

| PLC Electrical Control Board | 1 Unit |

| Hydraulic Stations | 1 Unit |

| Run Out Table | 1 Unit |

Our Advantages

Machine Pictures