Jiangsu LCD Technology Co., Ltd |

|

Working procedure

Decoiler – roll forming—Polyurethane Foaming and Injecting—Heating-- Compressing—Cutting--– product to run out table

Main technical datas

1). Dimension: 1700mm*1000mm*800mm

2). Width of feeding: Max 1500mm

3). Maximum loading coil weight: 5000kg

4). Inter diameter: 450-510mm

5). Mode of expand &fight: Inner expand &fight by Hydraulic

6). Way of feeding: Manual

7). PU foam thickness: 10-300mm

8). Standard Sandwich Panel Size: Max1250mm x 4000mm( W*L*H)

9). Linear Speed of production: 2-5 m/min

10). Maximum sheet embossing speed: 10 m/min

11). Reciprocating times of injection head: <60( per minute)

12). Production type: Continuous production with PLC controlling

13). Composite structure: Position fixed by double rubber tracker

14). Foaming system: Totally automatically continuous foaming, quantity of foaming could be stepless adjustable

15). Main Power of production: ≥ 35KW

16). Cutting: Pneumatic piston driving, non-stop cutting via sliding table

17). Electronic controlling system: Full-frequency PLC controlling system

18). Raw Material: 0.4-0.8mm

19). Coil Width: 1250mm or customized

20). Working Speed: 0-10 m/min

21). Roller Material: Superior alloy steel forged parts

22): Roller Size: ¢320mmx 1250 (Coil width)

23). Main Motor Power: 11KW

Introduction

1. The solidify of eps sandwich panel is be conveyed by double rubber belt.

2. The length of the BELT machine is about 24m, which consists of upper frame and lower frame,each frame has two sections.

3. The width of rubber board is 1100mm, the range of adjusting distance between upper and lower rubber board: 30mm,40mm,50mm .Horizontal distance between the two sides can not be adjusted.

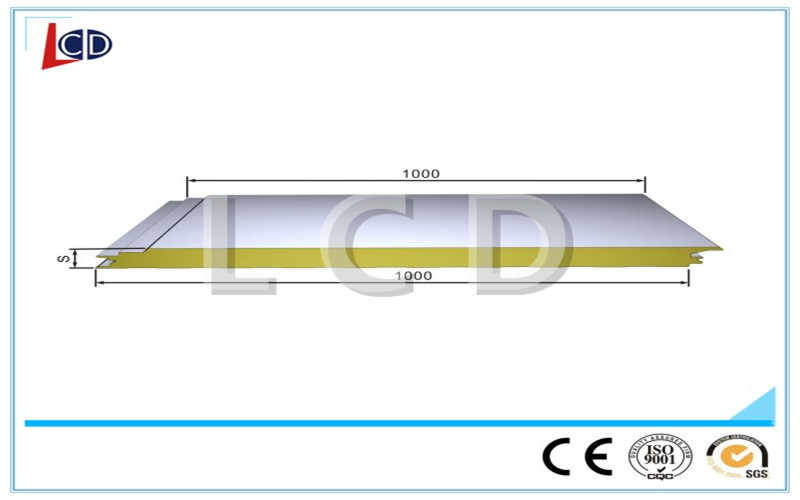

Brief introduction

This production line is a kind of specialized equipment for producing sandwich panel with the middle layer of anti-combustion polyurethane and with aluminum foil as the top and bottom face layer.s The sandwich panel is 10-40mm in thickness, 1250mm in width, length determined by the customer. The sandwich panel is mainly used as keeping warm for wall and roof (or ceiling). Different insulating panels with other soft facing layers could also be produced on the line.

Machine pictures