HANGZHOU QIANHE PRECISION MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

Wire Guide Tubes Stator Winding Needles Inner Bore 0.2mm Mirror Polishig CW0202-2006-3008

Precision polishing Coil Winding Nozzle

We supply high quality Tungsten carbide coil winding nozzle and Ruby tipped coil

winding nozzle for Nittoku coil winding machine, CNC Automatic coil winding machine

and other brand coil winding machines,.

There is description and features about the Tungsten Carbide Nozzle as following:

Tungsten Carbide nozzle is used on coil winding machine.it is made precisely of super

hard alloy and enjoys the hardness over HRA90.degree while the anti bending degree

reached over 2300N/mm.Two terminals and the inner and outlet are all receive mirror

surface treatment to ensure enameled wire makes no scrape. High hardness, resistance

to flexure, block and impact .

Tungsten Carbide Coil Winding Nozzle is required for guiding copper wire while winding of electronic assemblies including transformers or motor structures. It is made of superior quality tungsten carbide material and is appreciated for having smooth & strong structural configuration. This nozzle is perfect to be installed in automatic winding machines assuring their superior performance. Tungsten Carbide Coil Winding Nozzle offered by us is greatly admired to ensure smooth wire traveling without causing any stress during winding operation.

Features

· Concentricity is within 0.01mm

· Assures perfect straightness & stiffness of wire

· Superior wear resistance

TUNGSTEN CARBIDE NOZZLES (W SERIES)

Qianhe’s Carbide nozzles Series is made of tungsten carbide material, with a hardness upto HRA90 and above, and bending resistance up to 2300N/mm. It has an excellent balance between the wear resistance and being too brittle. Each nozzle is made of a solid piece of material with no joints so as to ensure a smooth path for wire travel. The inner bore is ground and polished to Ra0.1. Both the inlet and outlet radii are scientifically calculated and processed to a surface finish ofRa0.025, ensuring smooth travelling and minimal stress to the wire during winding. Concentricity between the clamping diameter and the outlet diameter is0.01mm. The inner bore diameter's tolerance is 0.01mm. It is excellent for precision coil layering.

Advantages

Specification and description:

| Part.No. | Model | Specifications(mm) | |||||

| L | L1 | D | D1 | d1 | d2 | ||

| 1 | W0202-2005-1505 | 15 | 5 | 2.0 | 0.5 | 0.2 | 0.2 |

| 2 | W0202-2000-3300 | 33 | * | 2.0 | * | 0.2 | 0.2 |

| 3 | W0202-3010-3015 | 30 | 15 | 3.0 | 1.0 | 0.2 | 0.2 |

| 4 | W0202-3006-3010 | 30 | 10 | 3.0 | 0.6 | 0.2 | 0.2 |

| 5 | W0202-3015-3015 | 30 | 15 | 3.0 | 1.5 | 0.2 | 0.2 |

| 6 | W0202-3007-3508 | 35 | 8 | 3.0 | 0.7 | 0.2 | 0.2 |

| 7 | W0303-3008-3012P | 30 | 12 | 3.0 | 0.8 | 0.3 | 0.3 |

| 8 | W0303-3012-3519 | 35 | 19 | 3.0 | 1.2 | 0.3 | 0.3 |

| 9 | W0303-3008-4506 | 46 | 6 | 3.0 | 0.8 | 0.3 | 0.3 |

| 10 | W0303-3020-3515 | 35 | 15 | 3.0 | 2.0 | 0.3 | 0.3 |

| 11 | W0303-0800-3500 | 35 | * | 0.8 | * | 0.3 | 0.3 |

| 12 | W0303-3018-4018 | 40 | 18 | 3.0 | 1.8 | 0.3 | 0.3 |

| 13 | W0404-3010-3009 | 30 | 9 | 3.0 | 1.0 | 0.4 | 0.4 |

| 14 | W0404-3007-4528 | 45 | 28 | 3.0 | 0.7 | 0.4 | 0.4 |

| 15 | W0505-3012-4506T | 45 | 6 | 3.0 | 1.2 | 0.5 | 0.5 |

| 16 | W0606-3012-3520 | 35 | 20 | 3.0 | 1.2 | 0.6 | 0.6 |

| 17 | W0606-3016-4010T | 40 | 10 | 3.0 | 1.6 | 0.6 | 0.6 |

| 18 | W0808-3018-3518 | 35 | 18 | 3.0 | 1.8 | 0.8 | 0.8 |

| 19 | W0808-3018-3010 | 30 | 10 | 3.0 | 1.8 | 0.8 | 0.8 |

| 20 | W1212-3022-3010 | 30 | 10 | 3.0 | 2.2 | 1.2 | 1.2 |

All size can be customized according to customer requirements

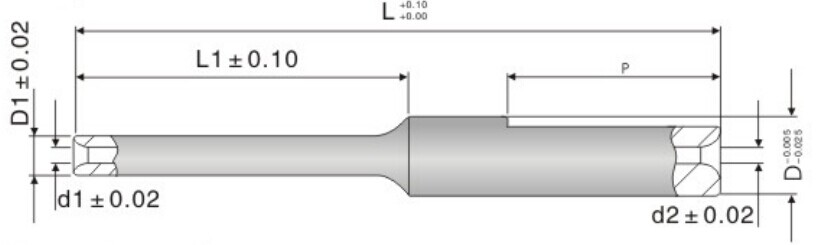

Nozzle Drawings:

The the measurements drawing as above please confirm your nozzles size according

to your winding machine and coil products.

Picture show :

Nozzle inspection

Why do you choose us?

1.100% manufacturer

In hardware tools, the wire winding machine training industry has

more than 10 years of

experience, we have more than and 100 skilled workers.

2. competitive price

One-stop service, from the material of die cutting process,

production, QC, packaging,

delivery. We are sure we produce all the goods. And the quality is 100% rest

assured. Many

customers are very happy to cooperate with us, because we can provide a more

competitive

price as a factory.

3,The best choice of material

All of our goods are the best material from the best suppliers,

whether the material is qualified

can be checked.

4. Quality Control

Before shipment, there are specialized personnel checks, each

product in the packaging before

the inspection is qualified. We guarantee that each product

shipment is perfect for sale.

5. Good service

We promise to answer your question in 24 hours.