Jiangsu Sunyi Machinery Co., Ltd. |

|

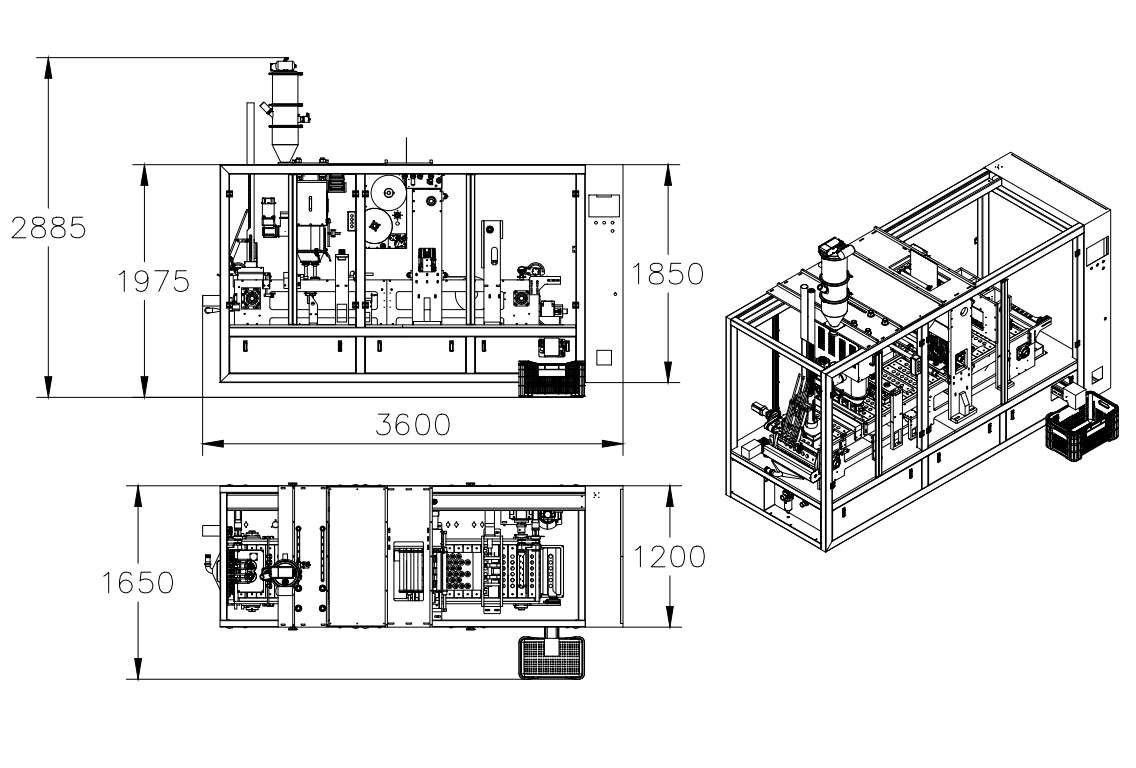

SKP-6 high capacity cup coffee capsule filling sealing machine

coffee capsule kcup

Introduction of the kcup filling sealing machine line:

This high automation complete kcup coffee capsule filling sealing line solutions with new technical characteristics all made of high quality sus304. All components come from world famous brands.

suitable capsules: nesprsso, lavazza, dolce gusto, kcup, point, any kind of container

suitable materials: powder, granule, liquid materials, such as: coffee powder, milk powder, pepper, shampoo and so on

capacity: 14400bph

Parameters of the kcup filling sealing machine line:

| Product Parameters | |

| SKP-1N Rotary Nespresso compatible coffee capsule filling and sealing machine | |

| All the product contact parts are food grade stainless steel AISI 304. | |

| Certificate | CE, SGS , ISO 9001,FDA, CSA, UL |

| The packed object | Fresh ground coffee; instant coffee; tea products; other food powder |

| Capacity | 2700 – 3000 pcs/hour |

| Filling system | Auger filler driven by servo motor |

| Filling accuracy | ±0.15 g |

| Filling range | 0-20 g |

| Sealing | Pre-cut lid sealing or Roll film cutting-sealing |

| Hopper capacity | 10 L |

| Power | 2,5 KW |

| Voltage | Single phase, 220 V,50/60 HZ |

| Compressed air consumption | ≥300 L/minute |

| Compressed air supply | Dry compressed air, ≥6 Bar |

| Weight | 600 Kg |

| Dimension | 3600 mmX1650mmX2885 mm |

| Delivery packaging | Wooden box |

This whole kcup filling sealing line includes:

Detailed procedures of the filling sealing machine line:

1. capsules automatically loading, one lane can store 300 capsules

2. capsules detection, once the sensor detects the empty capsules, the machine will continue the following procedures, like filling, sealing procedures. To make sure each capsule can be well produced.

3. auger filling. you can change the filling material and the filling weight by yourself.

4. robort arms automatically seize and put the pre-cut films into the middle of the capsules, and in this station, has a detection, to detects if each capsule with a film. If not, the machine will set alarms

5. two procedures for heat sealing which can efficiently avoid the risks of sealing failure.

6. output conveyor. the robort arms will pick out the fininshed capsules onto the conveyor belt. and this conveyor can be connected with the bag packaging machine / box cartoning machine

From the filling step to the sealing step, there would be a nitrogen flushing system, which can make the residual oxygen less than 2%, greatly prolong the capsules' lifetime.