Shenyang Top New Material Co.,Ltd |

|

Verified Suppliers

|

|

Cobalt Alloy 6 Heating Rod 38 - 55HRC Hardness

1. Cobalt alloys have higher melting points than nickel (or iron) alloys ,This gives them the ability to absorb stress to a higher absolute temperature .

2. Cobalt alloys give superior hot corrosion resistance to gas

turbine atmospheres , this is due to their high chromium content.

3. Cobalt alloys show superior thermal fatigue resistance and

weldability over nickel alloys .

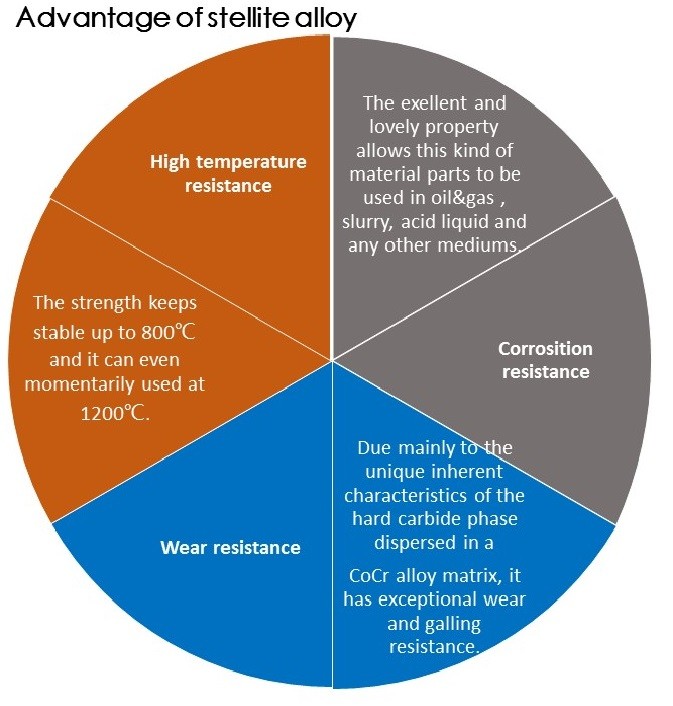

--Excellent high temperature and corrosion resistance even at high temperature up to 800℃

SYTOP cobalt base alloys is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

Chemical compositions and properties (%)

| Brand | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | P | S | Density (g/cm3) | Hardness (HRC) |

| ST 3 | 2.0-2.7 | 1.0 | 1.0 | 29-33 | 3.0 | 11-14 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.55 | 51-55 | |

| ST 6 | 0.9-1.4 | 1.0 | 1.5 | 27-31 | 3.0 | 1.5 | 3.5-5.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.35 | 38-44 |

| ST 12 | 1.1-1.7 | 1.0 | 1.0 | 28-32 | 3.0 | 7.0-9.5 | Bal. | 3.0 | ≤0.03 | ≤0.03 | 8.40 | 44-49 | |

| ST 20 | 2.2-3.0 | 2.0 | 30-34 | 3.0 | 1.0 | 14-18 | Bal. | 3.0 | ≤0.05 | ≤0.05 | 8.65 | 53-59 | |

| Tantung-G 25 | 2.2-2.8 | 1-3 | 27-32 | 7 | Ta/Nb | 14-19 | Bal. | 2-5 | 8.84 | 57-60 | |||

| Tantung-G35 | 3.3-3.8 | 1-3 | 27-32 | 7 | Ta/Nb | 14-19 | Bal. | 2-5 | 8.80 | 60-63 | |||

| Tribaloy 400 | 0.04 | 2.5-2.7 | 8-10 | 27-29 | Bal. | 55 | |||||||

| Tribaloy 800 | 0.04 | 3.2-3.6 | 16-18 | 27-29 | Bal. | 58 |

Production process of our thermowell tube

1. Powder metallurgy process

A. Better metallurgical structure, better strength

B. Various types of automatic pressing machines from 3 tons to 630 tons. The ordered profiles can be very flexible.

2. Investment casting process

Different volume of furnaces, the order quantity can be very flexible.

3. Machining

CNC, lathing, drilling, milling, grinding, wire cutting, polishing

Production process

Powder metallurgy pocess. It has better strength than casting parts, better granule structure and avoiding the troubles caused by casting defects.

FAQ

Q1: What is the Warranty for our products ?

A1: We own high precision grading machine to control geometry dimensions and apply ultra fine grain size substrate coated with high performance coatings to guarantee the lifetime of our products, which can satisfy every working condition.If any quality problems on our side occurred in this period , we will take on the shipping cost and replacement.

Q2: Do you provide free samples?

A2: Yes, usually we provide free samples for testing under the condition of freight paid by customer.

Q3: What is your minimum order requirement?

A3: We will indicate the MOQ for each item in the quotation sheet. We accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

Q4: What is the delivery time of your products?

A4: It depends on the inventory availability.If items needed are in stock, the delivery time would be within 8 work days, but if not the delivery time would be around 20 work days.

Q5: Can you manufacture Special-shaped products?

A5: Yes, we can. We can produce both standard and special prosucts. We can make them according to your drawings and samples.

Q6: May I have my order working schedule ?

A6: Yes, we will send working schedule of your order each week. We will inspect and test all merchandise in case of damaging and missing parts before shipment. The detailed inspection pictures of the order will be sent to you for your confirmation before delivery.

Best Service

1. Drawing made and products design

Our professional engineer team supply drawing design service .

2. A entire process supervising

Our sales team will update the whole progress to you .

3. Good English communication and export service .

4. Quickly reply and provide professional solution to your project.

Send your inquiry details right now !!!