Shandong Decho Building Materials Technology Co., Ltd |

|

Verified Suppliers

|

|

Introduction:

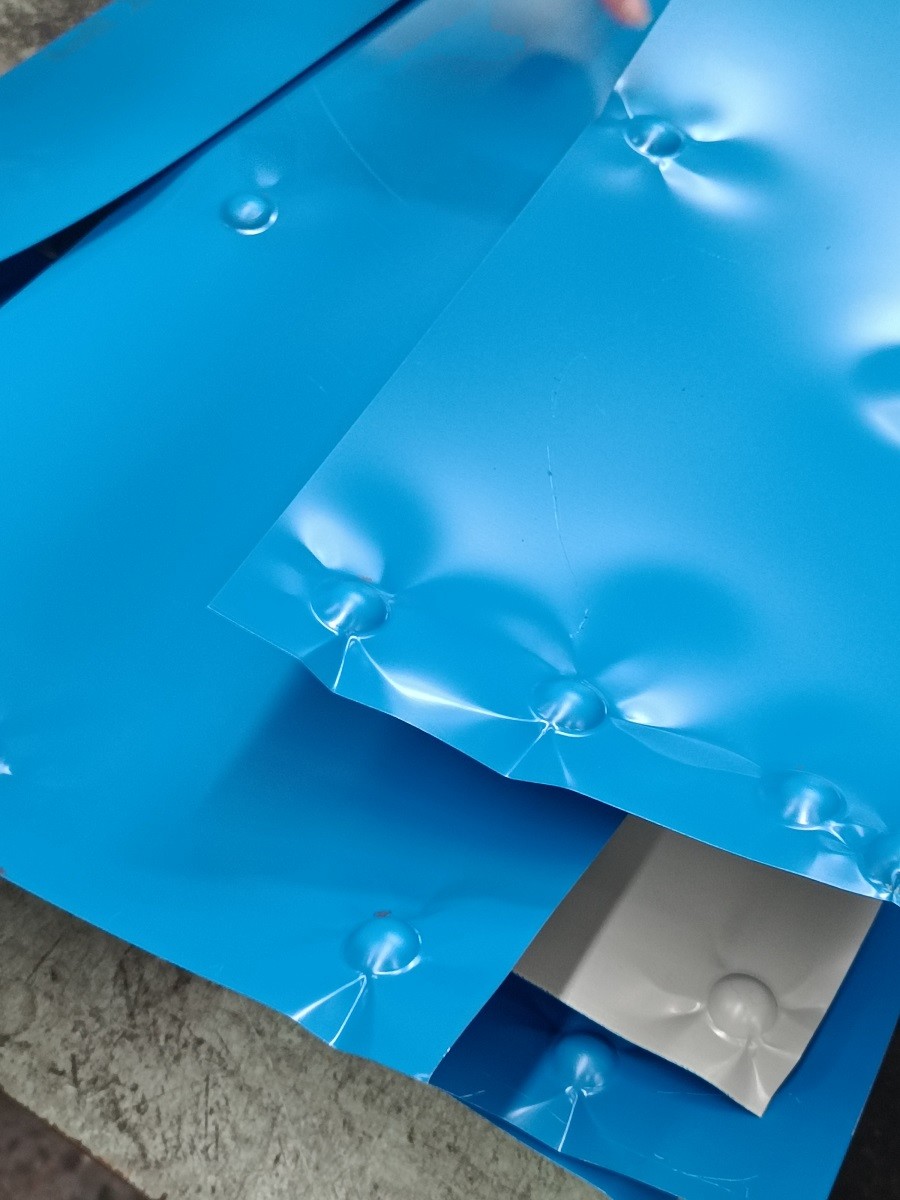

Colour coated coil is a product made from hot-dip galvanised sheet, hot-dip aluminium zinc plated sheet, electro galvanised sheet, etc., which is pre-treated (chemical degreasing and chemical conversion treatment) and then coated with one or several layers of organic paint and subsequently baked and cured. Because of the coating of different colours of organic paint coloured steel coil and so named, referred to as colour coated coil.

The use of hot-dip galvanised steel strip as the substrate of the colour coated steel strip in addition to the zinc layer protection, the zinc layer on the organic coating plays a role in covering and protecting the steel strip to prevent rust, the service life of the steel strip is longer than the galvanised strip, about 1.5 times.

Colour Coated Coil Usage:

Colour coated coil has light weight, beautiful and good anti-corrosion properties, and can be directly processed, the colour is generally divided into grey and white, sea blue, brick red, mainly used in advertising, construction, home appliance industry, electrical appliances industry, furniture industry and transport industry.

The coatings used for colour coated rolls are selected according to the use of different environments with suitable resins, such as polyester silicone modified polyester, polyvinyl chloride plastisol, polyvinylidene chloride and so on. Users can choose according to the use.

Coating Structures:

Type of coating structure

2/1: Coat upper surface twice, lower surface once, bake twice.

2/1M: Coat upper and lower surfaces twice, bake once.

2/2: Top and bottom surfaces are coated twice each and baked twice.

Usage of different coating structures:

2/1: The corrosion resistance and scratch resistance of single layer back coating is poor, but it has good adhesion, mainly used for sandwich panels.

It is mainly used for sandwich panels;

2/1M: backcoat with good corrosion resistance, scratch resistance and moulding properties, good adhesion, suitable for single-layer compression moulding panels.

2/1M: good corrosion resistance, scratch resistance and moulding properties, good adhesion, suitable for single-layer pressboards and sandwich panels.

2/2: double-layer backing paint with good corrosion resistance, scratch resistance and processability, mostly used for single-layer pressboards, but with good adhesion.

Most of them are used for single-layer moulding board, but its adhesion is not good, and it is not suitable for sandwich board.

Colour Coated Coil Coating Types:

Good adhesion, rich colours, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicone Modified Polyester (SMP), good film hardness, abrasion and heat resistance, as well as good exterior durability and resistance to chalking, gloss retention, general flexibility, medium cost.

(HDP), excellent colour retention and UV resistance, excellent exterior durability and chalking resistance, good film adhesion, rich colour, excellent cost performance.

(PVDF), excellent colour retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited colours, high cost.

Detailed Parameters:

| Pre-Painted Galvalume Steel Coils | |||

| Commercial Quality Steel | ASTM A755M-03 | EN10327-2004 | JIS G 3322:2012 |

| CS | DX51D+AZ | CGLCC | |

| Structural Quality Steel | SS GRADE 230 | S220GD+AZ | CGLC340 |

| SS GRADE 255 | S250GD+AZ | CGLC400 | |

| SS GRADE 275 | S280GD+AZ | CGLC440 | |

| SS GRADE 340 | S320GD+AZ | CGLC490 | |

| SS GRADE 550 | S350GD+AZ | CGLC570 | |

| S550GD+AZ | |||

| Pre-Painted Galvanized Steel Coils | |||

| Commercial Quality Steel | ASTM A755M-03 | EN10327-2004 | JIS G 3312:2012 |

| CS | DX51D+Z | CGCC | |

| Structural Quality Steel | SS GRADE 230 | S220GD+Z | CGC340 |

| SS GRADE 255 | S250GD+Z | CGC400 | |

| SS GRADE 275 | S280GD+Z | CGC440 | |

| SS GRADE 340 | S320GD+Z | CGC490 | |

| SS GRADE 550 | S350GD+Z | CGC570 | |

| S550GD+Z | |||

| SPECFICATION | |||

| PRE-PAINTED GALVANIZED STEEL COIL | PRE-PAINTED ALUZINC STEEL COIL | ||

| Thickness | 0.15MM--1.50MM(BMT) | 0.15MM--1.50MM(BMT) | |

| Width | 900MM-1340MM | 900MM-1340MM | |

| Zinc/AZ | 30g/m2-275g/m2 | 30g/m2-185g/m2 | |

| Base Metal | Galvanized Steel Coil | Galvalume/ Aluzinc Steel Coil | |

| Paint Coating System | POLYESTER(PE),RMP, SMP,Super-SMP, HDP,Super HDP, PVDF | ||

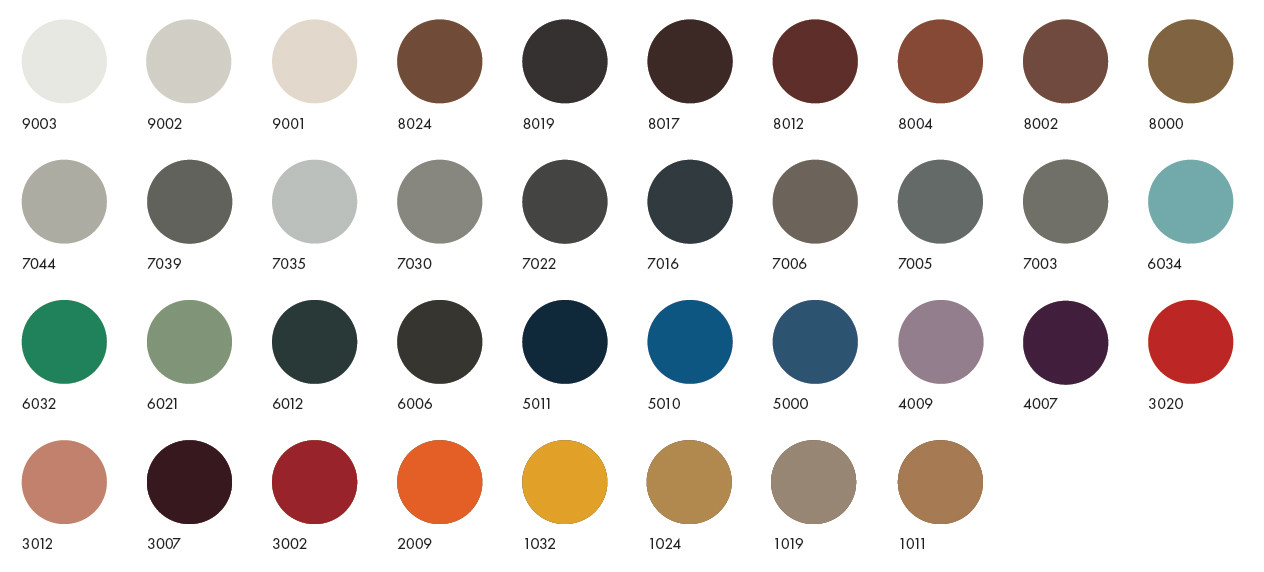

| Color | RAL / Customized | ||

| Coil weight | 1.5MT-10MT | ||

| Coil ID | 508MM OR 610MM | ||

| * HARD QUALITY GALVANIZED STEEL(HRB75-HRB90) AVAILABLE ON CUSTOMER'S REQUEST | |||

| Coating performance | |||||||

| CATEGORY | T Bending | Impacting | Salt spray test(hours) | MEK | Hardness | Gloss 60° | Color Tolerance ΔE |

| PE | ≤3T | ≥9 | ≥500 | ≥100 | ≥F | 10-85 | ≤0.8 |

| SMP | ≤3T | ≥9 | ≥500 | ≥100 | ≥F | 10-85 | ≤0.8 |

| HDP | ≤2T | ≥9 | ≥1000 | ≥100 | ≥HB | 10-85 | ≤0.8 |

| PVDF | ≤2T | ≥9 | ≥1000 | ≥100 | ≥HB | 10-85 | ≤0.8 |

Test Process & Results:

Paint Suppliers & Partners:

We only choose the top-level paint suppliers for our pre-painted steel coils and sheets,

AkzoNobel, Sherwin-Williams Valspar, Beckers, PPG Industries, Nippon, KCC are our solid paint suppliers.

Their best paint materials decide our steel coils quality.

Package & Delivery Shipment :

Delivery time: 30 days deliver to loading port

Shipment Methods: Container, Breakbulk, Railway, Trucks

Projects:

Why Choose Us:

DECHO building colour steel plate can meet the need to use colour steel plate as raw material for building. Decho Building Materials colour steel plate is mainly processed into, for example, colour steel corrugated board or colour steel composite sandwich board after our colour steel plate is widely used in the construction of airports, freezers, steel plants, warehouses, and other industrial buildings and commercial buildings, such as the roof of the colour steel tiles, colour steel plate sandwich walls and doors.

Reasons for choosing Decho Building Materials new material:

Welcome to enquire.