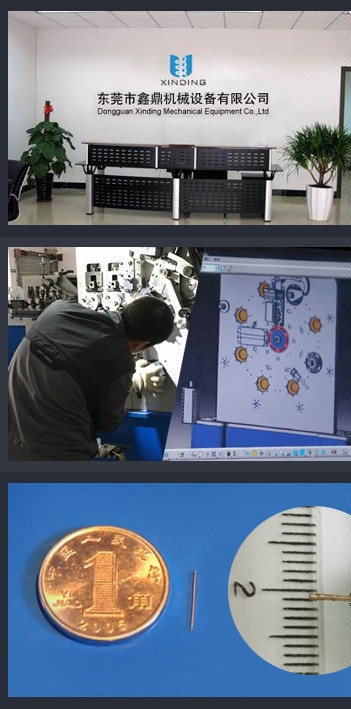

Dongguan Xinding Mechanical Equipment Co.,Ltd |

|

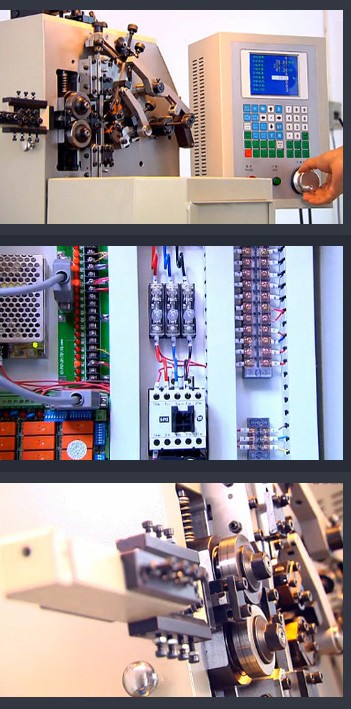

High Precision 5 Axis CNC Spring Forming Machine With Wire Rotation And Spinner

| DETAIL DESCRIPTION |

| 1.Axis count: | 5 axis |

| 2.Wire size: | ¢0.30-2.50mm |

| 3.Max outside diameter: | ¢70mm |

| 4.Wire feed motor: | 2.7kw |

| 5.Cam motor: | 2.7kw |

| 6.Wire rotation motor: | 2.7kw |

| 7.Quill motor: | 1kw |

| 8.Spinner motor: | 0.4kw |

| 9.Computer display: | Chinese/English |

| 10.Max wire feed: | 99999.99mm |

| 11.Min wire feed: | 0.02mm |

| 12.Computer memory: | 1000 programs |

| 10.Dimensions: | 1400*1100*1800mm |

| 11.Weight: | 1250kg |

| 12.Power ac: | 3-phase 380v 50hz |

| PRODUCTION FEATURES |

1. XD-CNC20W spring machine consists of cam axis, wire feeding axis, wire rotation, quill and spinner axis. mechanical part has eight sets of sliding blocks.

2. Computerized cam rotation system can be set from 0.1-359.9°,

every two wire feeding wheels constitutes of one group, totally two

groups.

3. XD-CNC20W cnc spring machine is equipped with XinDing 5 axis

spring machine controller. which can save 1000 files, axis

location, feeding data.wire rotation position, production speed and

production output are displayed on the screen.

| The company has always dedicated research and development, design, manufacture, sales and service in CNC spring machine equipment industry. |

| We have professional teams, expert in production, design and R&D for over 10 years to meet clients' different demands. | |

| Our machine produce high presicion spring at 0.07mm wire diameter. |

| High precison and excellent performance for producing all kinds of springs and wire forms, Sanyo Denki servo motor for each machine axis, each axis is controlled by a seperate machine CNC. |  |

| Machine test run(at least for one week) is a must before we ship the machine, in an effort to insure every mechanical and electrical parts are in perfect condition. | |

| After order placed, we accept to adjust the products according to customer's demand, and remain the program and tool settings on machine. in order to insure a quick start of machine once customer receive it. |

| OUR FACTORY & OFFICE |

| TIPS ON MACHINE MAINTENANCE |

| www.springxd.com |

| +86 13580987891 | |

| 0769-85560118 | |

| 0769-82883433 | |

| mr-bai | |

| sales@springxd.com, xinding@springmachine.net | |

| No. 7, Hongmian Road, Dabandi Industrial Park, Humen Town, Dongguan, Guangdong, China |