Anhui YUANJING Machine Company |

|

Steel Light Pole Welding Machine

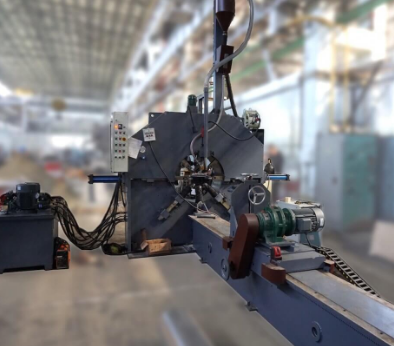

This machine composed by main machine head, tractive body and

feeding shelf. Tractive body was moved by collet in small vehicle

nipping the steel pole’s collet. When the small vehicle moved,

driven steel Pole, from small collet to big collet, Regularity

moved. The big side of the steel pole was hold by feeding vehicle,

Force automatic sewing from head of machine to steerable wheel.

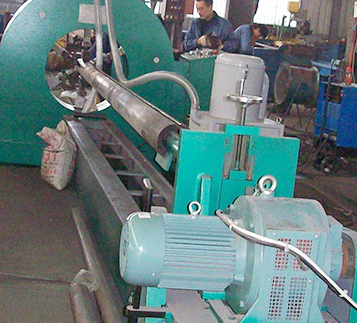

At one time, the welding machine starts welding. This machine adopt

multiple wire submerged arc welding, solder was reclaimed

automatic. Welding line was symmetrical and slinky. It has strong

filter, Forming one time, And be with high welding efficiency.

The speed of welding achieve 2 to 3 meters per minutes, Is about 3

times of the gas welding .The cost of the welding is lower than gas

welding. It is with speedy welding, high efficiency, And lowest

price in china light poles industry now.

it is suitable for one piece type polygonal and circle taper light pole. it is automatic welding line, the trolley with inverter speed adjustable motor can pull the light pole from small end to big end, The hydraulic cylinder through mechanical chain, worm wheel push the clamping wheel to close the pole and do welding at same time.

>LIGHT POLE

Suitable for various steel light poles welding;

Semiautomatic pole welding increase speed much;

Good and stable welding seam

>Main Welder

Hydraulic and mechanic pole holding system;

Synchronized 6-8pcs press;

Welding start from small end to big end;

Hold pole properly during weld;

>Motorized trolley

Speed adjustable motorized;

Pole clamp height adjustable;

Big pulling force for various size;

Guide way length can be configured according to various pole

length.

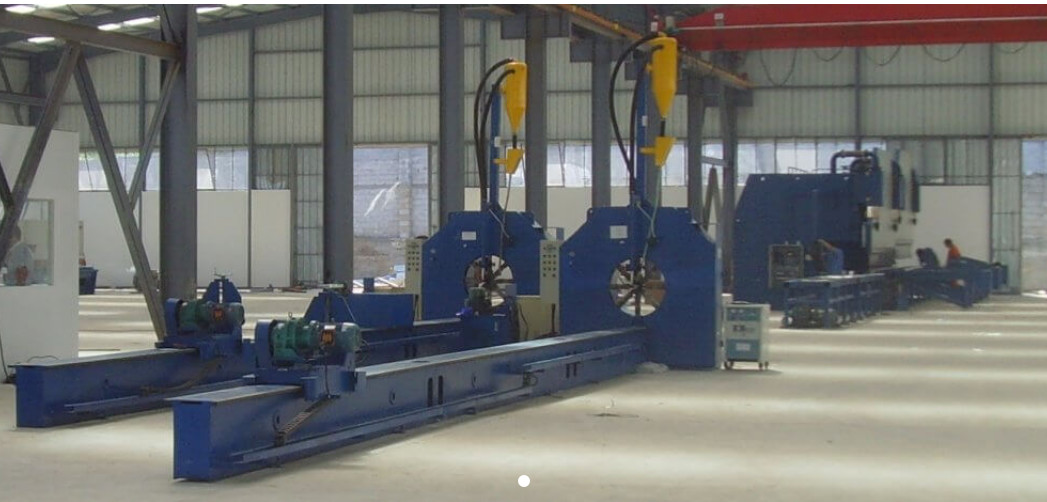

Light Pole Welder

Long guide working table with rack for pull dolly;

Motorized Dolly for pulling pole during pole welding;

Hydraulic clamping and welding unit

(3 sets clamping wheels for polygonal and circle pole);

Submerged Arc Welding and Gas-shielded welding(CO2) Welding system,

including welding wire feeding system.

The submerge welding flux recovering system;

Steel pole back support unit after welding;

Hydraulic station for whole system;

WELDING

Both Co2 shielded welding or Submerge welding can be applied on

steel light pole welding machine.

Submerge welding can be easier for beginner and it has no welding arc, is better for operator protection.

It is easier to check weld seam.

Co2 welding can be more popular for normal welding shop.

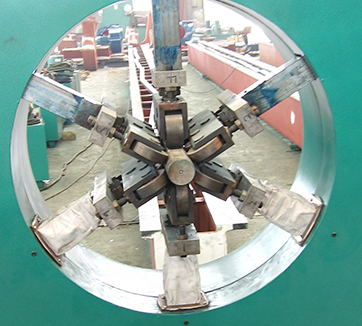

Main Welding Head

With 8 or 6 Pieces Pole holders, mechanical synchronized ;

Each holder will be with 3 rollers for Octagonal or Conic pole;

Holders will press and close pole seam properly during welding for

any pole slope rate;

With welding seam guider to make straight welding.

Operator can manually trace and adjust welding point even weld seam

twist;

Both Co2 or submerged welding can be applied;

Welding will be much stable and faster;

Welder Control

Start or stop Hydraulic station;

Control pole holders open , close or holding (in welding);

Steel pole pulling trolley frequency converter is adjustable from

control cabinet, moving speed;

Pole pulling trolley move forward / backward control;

Welding seam motorized guider vertical movement control;

Hydraulic assit pressing cylinders control;

Assist hydraulic station on/off control;

Move Trolley

Backward and forward control;

Speed is adjustable by frequency inverter;

Heavy driving gear and rack make big pulling force for heavy poles;

Pole pulling trolley move forward / backward control;

Quick and easy adjust pole holding clamp;

Hydraulic assit pressing cylinders control;

Quick clutch for trolley back movement (optional motorized);

| max light pole diameter | 340/450/500mm |

| Pole shape | conic/octagonal/polygonal |

| Pole wall thickness | 3~6mm |

| Max length | 10/12/14/16m |

| Suitable pole shape | conic steel pole, octagon steel pole or polygonal poles. |

| Operator numbers | 2 people |

| Welding Way | semi-automatic submerged arc welding |

Main Technology Parameter

| No | Model | Value | Unit |

| 1 | SEAM LENGTH | ≤14000 | mm |

| 2 | MAX SEAM THICKNESS | 5 | mm |

| 3 | HOST HEADER SIZE(L*W*H) | 1500*480*1645 | mm |

| 4 | WORKTABLE SIZE(L*W*H) | 15500*400*480 | mm |

| 5 | MAX SEAM DIAMETER | 500 | mm |

| 6 | MIN SEAM DIAMETER | 60 | mm |

| 7 | WELDING CURRENT | 630 | A |

| 8 | WALKING DEVICE MOTOR | 3 | KW |

| 9 | OIL PUMP MOTOR | 3 | KW |

| 10 | RECOVERY MOTOR | 2.2 | KW |

| 11 | GEAR PUMP | 25 | ml/r |

| 12 | MAX PRESSURE SYSTEM | 20 | MPa |

| 13 | SYSTEM WORKING PRESSURE | ≤5 | MPa |

| 14 | MACHINE SIZE | 33000X1600X1650 | mm |

Main spare parts supplier:

| NAME | SPEC. | SUPPLIER | ||

| 1 | GEAR PUMP | 25 ABOVE DISPLACEMENT | 1SET | HUAIYIN | |

| 2 | GEAR PUMP MOTOR | 3KW | 1SET | SIEMENS BADE | |

| 3 | BENCHER | 3KW | 1SET | SIEMENS BADE | |

| 4 | REDUCER | BWD220 | 1SET | DAJIANG | |

| 5 | SEALINGS | FULL SETS | 1SET | IMPORT FROM JAPAN | |

| 6 | ELECTRIC COMPONENTS | 1SET | SCHNEIDER | ||

| 7 | HYDRAULIC OIL | 46# ANTI-WEAR HYDRAULIC OIL | 1BARREL | SHANGHAI(CHARGED BY USER) | |

| 8 | BEARINGS | 1SET | |||

| 9 | HYDRAULIC VALVE STACK | DEDICATED SYSTEM | 1SET | HARBIN | |

| 10 | CYLINDER | SPECIAL CYLINDER | 1SET | HOME MADE | |

| 11 | UBMERGED ARC WELDING MACHINE | 630A | 1SET | HOME MADE | |

| 12 | WIRE FEEDING | 1SET | SHANGHAI | ||

| 13 | RECYCLING MACHINE | 1SET | SHANGHAI | ||

| 14 | LINE PANEL | 1SET | WUXI |

|  |

| |

| |